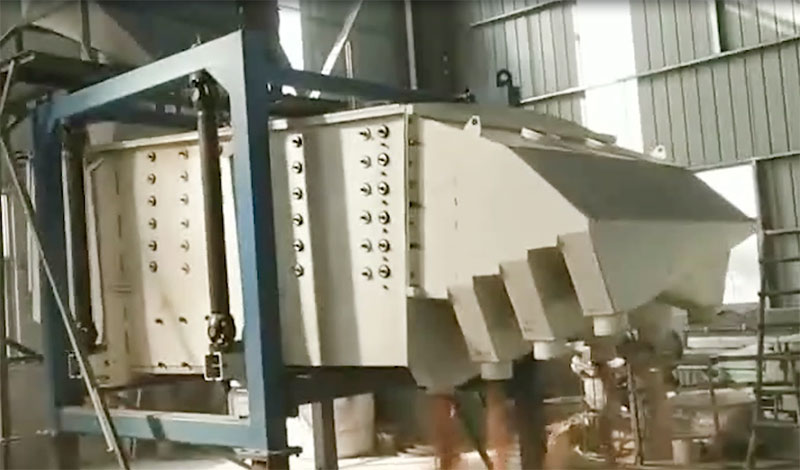

Application Note for Quartz Sand Square Tumbler Screen

Friday February-14 2025 10:32:42

Quartz sand Square Tumbler Screen is mainly used for primary screening and grading of quartz sand, the particle size range is 1-0.5mm, 0.5-0.1mm, 0.1-0.01mm, 0.01-0.005mm.

Quartz sand square drum screen mesh number

For the coarse crushing particles of raw quartz ore, such as 32mm, 16mm, 8mm, 4mm, 2mm and other specifications, Dahan Machinery currently has a corresponding series of machines. And for the screening of quartz sand of 10 mesh-20 mesh, 20 mesh-40 mesh, 40 mesh-80 mesh, 100 mesh-120 mesh, there are also detailed production processes. In addition, we can also customize and develop suitable models according to the specific production capacity requirements or other special requirements of customers.There are three types of quartz sand: ordinary quartz sand, semi-refined quartz sand and fine quartz sand. Quartz sand is larger than 120 mesh, and quartz powder is smaller than 120 mesh.

| model | Effective screening area(m²) | power(KW) | Rotation frequency(r/min) | Screen box stroke(mm) |

| FYBS1030 | 3 | 3 | 180-260 | 25-60 |

| FYBS1036 | 3.6 | 3 | ||

| FYBS1230 | 3.6 | 4 | ||

| FYBS1236 | 4.32 | 4 | ||

| FYBS1530 | 4.5 | 5.5 | ||

| FYBS1536 | 5.4 | 5.5 | ||

| FYBS1830 | 5.4 | 7.5 | ||

| FYBS1836 | 6.48 | 7.5 |

Application of square tumbler screen in quartz sand screening

It is specially used for screening and grading of quartz sand. It can process quartz sand particles or powder within the range of 0.5mm-32mm, and can perform multi-layer screening at the same time.

Quartz sand is a particle obtained by crushing quartz stone. Its main component is SiO2, which belongs to silicate minerals. Quartz has the characteristics of high hardness (Mohs hardness is 7), strong wear resistance and stable chemical properties. The color is usually milky white or colorless and translucent. As an important industrial raw material, quartz sand is not a chemical hazardous substance and is widely used in many fields, including glass manufacturing, casting, ceramic and refractory material production, ferrosilicon smelting, metallurgical flux, construction, chemicals, plastics, rubber, abrasives and filter materials.

Features of Quartz Sand Square Tumbler Screen

1. Two screen boxes can be designed for multiple screen layers, and the upper and lower screen boxes can work at the same time, which is 3-6 times the output of ordinary screen machines, and the output can reach more than 40 tons/hour.

2. During the screening process, 6 sieve plates can be installed to separate quartz sand of different specifications, and 7 kinds of quartz sand of different specifications can be separated, which can be divided into coarse, medium and fine-grained grades.

3. A distributor can be added in the feeding section to ensure that the screen is evenly distributed on the screen surface, and at the same time play a role in buffering and protecting the screen surface.

4. The upper cover of the equipment is designed with a dust removal device. It can be easily connected with on-site dust removal equipment. In a large-scale production line, multiple screening equipment can be configured.

Matters needing attention in Quartz Sand Square Tumbler Screen

In the quartz sand production line, Square Tumbler Screen is widely used, and its large screening capacity plays a decisive role in the quality and output of the produced stones and sand. In the sand and gravel production process, the use of the screening machine should also pay attention to some problems:

1. Screening from coarse to fine

If the sieving is from coarse to fine, the Square Tumbler Screen screen surfaces overlap according to the thickness, and the screen surface with a large screen surface should be placed on top, so that it is not easy to wear. If the excitation force of the sieving machine is increased, the fine particles can fully pass through all the sieve surfaces, thereby reducing the chance of being mixed in coarse-grained products.

2. Screening from fine to coarse

In the case of screening from fine to coarse, in order to facilitate the discharge, reduce the inclusion of fine particles accumulated in various specifications of discharge. With this screening sequence, the structure size of the Square Tumbler Screen is larger, and all materials will pass through the fine screen surface first, which will accelerate the wear of the fine screen surface.

3. Appropriate screening methods should be used

During the screening process, wet screening or dry screening should be selected according to the mud content and water content of the material in the sand screen machine. During the wet screening process, it is necessary to sprinkle water on the material of the screening machine to reduce the viscosity of the mud and rock and prevent the screen holes from being blocked. If dry screening is used, it is generally used when the mud content or water content is small.