Our screening range is capable of handling a wide variety of products manufactured in different industries. From small batch processing to large batch screening, we have the right sieve for you.

|

|

|

|

|

| Vibro Sifter | Ultrasonic Vibrating Screen | Direct Discharge Sifter | Tumbler Screen | |

| $800.00-$4,500.00/Set | $800.00-$3,000.00/Set | $760.00-$3,090.00/Set | $860.00-$3,680.00/set | |

| Capacity | 100-3300kg/h | 100-5000kg/h | 3-30 t/h | 6-60 t/h |

| Frequency | 1500 | 1500 | 1460(960) | 1500 |

| Mesh Size | 2-500 mesh | 10-635 mesh | 140 mesh | 500 mesh |

| Power | 0.25-3KW | 0.18-2.2 KW | 0.18-0.75 KW | 0.75-5.5 |

| Usage/Application | High-capacity screening of powders, granules, and liquids | For ultrafine powder screening, prevent mesh blinding and blocking with ultrasonic system | Connected in series at the front end of the production line, it is used to quickly remove impurities or agglomerates in powdered materials. | Imitating the manual sieving movement, it can gently sieve materials, suitable for fragile crystalline particles or fine powders, and the output is increased by 1.5 to 5 times. |

Improve product quality

Eliminate oversize and contamination from your powder or liquid slurries.

Increase production rate

Our industrial sieves achieve a higher throughput capacity than standard vibrating screens, 3 times higher throughput through precise sieving.

5 layers grading

The sieve industrial equipment provides up-to 5 levels of gradation for the removal of broken or undersized product while also grading the product by passing the product through a grid of up to 5 different pore sizes. precise particle size distribution in one single operation.

Small footprint

The compact form requires minimal headroom to easily fit into your existing production line.

Cut cleaning downtime

A tool-free, quick-release mechanism allows for easy disassembly and cleaning.

Eliminate dust and fumes

The enclosed sanitary screener ensures the total containment of screened materials.

less noise pollution

It comes with a rubber shock-absorbing and shock-isolation structure, which can protect the machine from damage while reducing the noise generated by the machine.

Sieve industrial equipment is widely used in the processing industry as an effective way to protect ingredients and final products from contamination and caking. Industrial sieves are usually made of a single-layer plate containing a screen that is used to screen out oversize, agglomerates and foreign bodies from liquids and powders. A motor attached to the screen uses an unbalanced force to create vibration, Accurate grading of materials by means of sieves equipped with 1 to 5 different aperture sizes, stacked on top of each other, the largest particles/parts are removed from the separator on the top sieve deck, and the finest particles are removed from the discharge port at the bottom.

Sieve industrial equipment is used to screen wet and dry materials to remove oversize and contaminants to improve the quality of your product. These industrial sieves are used in a variety of applications including sieving pharmaceutical powders, various food powders and powder coatings, and are also available in different sizes and options to suit your sieving requirements.

1. Removal of foreign matter: Used to remove broken or undersized products such as lumps and other contaminants for final quality inspection.

2. Classification: Accurately separate particles of different sizes from the product, so that the final material is classified into different sizes. This is usually achieved by passing the product through a grid of up to 5 different aperture sizes.

3. Solid-liquid separation: It can quickly remove insoluble solid substances in various slurries, and can contact slag discharge. Most are single-layered, but multiple layers can also be used.

4. Batch Screening: Improves product quality and safety by breaking down agglomerates and filtering out oversized particles, contaminants and debris, ideal for small processes, batch production or short production runs.

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

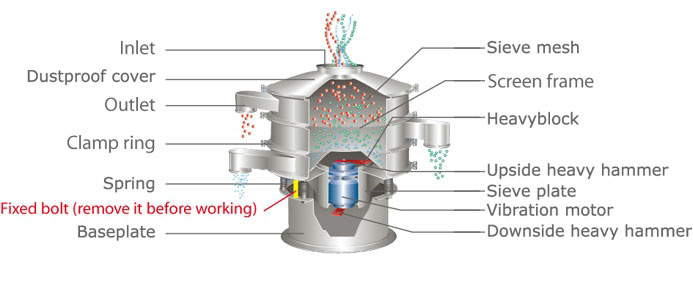

Dust cover: It is composed of feed inlet and cone, used to prevent material splashing and external pollution from entering the screen box, and the design of observation window can be added.

Screen frame and screen mesh: the main structure of the machine, materials are screened in the space formed by the screen frame and screen mesh, and can be disassembled and replaced freely.

Vibration motor: vertical vibration motor, divided into four specifications: 2, 4, 6, 8, and grades, the vibration times are 2870, 1460, 980, 740RPM respectively, and can be designed as explosion-proof type (selection for flammable and explosive production scenarios)

Screen cleaning device: clean the clogged materials in the screen holes and increase the output. There are two materials of silica gel and rubber to choose from, and an ultrasonic cleaning device (635 mesh) can also be selected.

Shock-absorbing spring: It is used to conduct the exciting force generated by the motor and play a role of buffering and shock-absorbing to prevent the upper screen body from breaking due to excessive vibration.

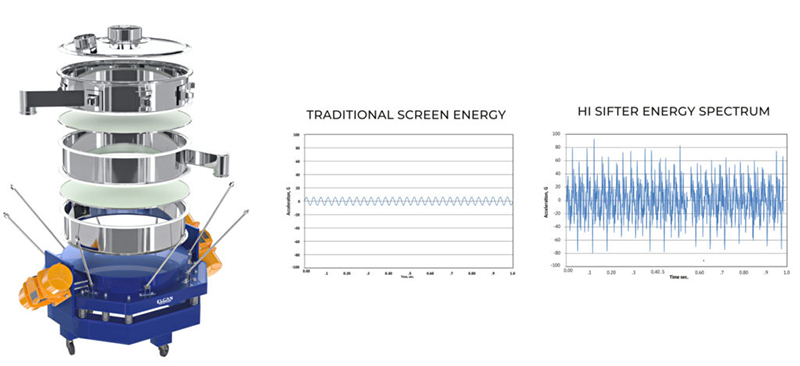

High output, high productivity, yield rate up to 98%

400mm, 700mm, 1000mm screen area

Single, double, triple layer configurations

Lowest operating cost compared to traditional ultrasonic screens and vibrating machines

Low noise (<85 dB), low energy consumption, no screen obstruction

Sieve industrial equipment is suitable for medium and large production in industrial screening. It can be used in the separation process of solids in liquids, for the separation of different particle sizes of the same product, for safety screening to eliminate foreign particles, for particle homogenization, etc. The table below is our sieve industrial equipment in different industries or application in material:

| PRODUCT | MESH LIGHT | DH-600 | DH-0800 | DH-1200 | DH-1500 |

| Milk powder | 400µ | 350Kg/h | 800Kg/h | 1,800Kg/h | 2,800Kg/h |

| Orange juice | 1000µ | 1,600l/h | 3,500l/h | 8,000l/h | 12,000l/h |

| Spices | 600µ | 400Kg/h | 1,000Kg/h | 1,500Kg/h | 1,800Kg/h |

| Peppers | 1000µ | 180Kg/h | 350Kg/h | 1,000Kg/h | 1,300Kg/h |

| Powdered sugar | 150µ | 800kg/h | 2,000 kg/h | 3,000kg/h | 3,500Kg/h |

| Wheat flour | 300µ | 300kg/h | 600kg/h | 1,350kg/h | 2,100Kg/h |

| polyethylene pellets | 3000µ | 600Kg/h | 1,300Kg/h | 3,000Kg/h | 4,500Kg/h |

| toner powder | 100µ | 90Kg/h | 170Kg/h | 400Kg/h | 600Kg/h |

| Crystal powder (container) | 100µ | 270Kg/h | 500Kg/h | 1,300Kg/h | 2,000Kg/h |

| shredded tire | 1000µ | 300Kg/h | 650Kg/h | 1,500Kg/h | 2,200Kg/h |

| Slurry | 125µ | 2,000l/h | 4,000l/h | 10,000l/h | 15,000l/h |

| recycled pet | 5000µ | 400Kg/h | 850Kg/h | 2,000Kg/h | 3,000Kg/h |

| biofuel oil | 200µ | 800l/h | 1,600l/h | 4,000l/h | 6,100l/h |

| acrylic paint | 80µ | 500l/h | 1,200l/h | 2,700l/h | 4,200l/h |

Sieve Industrial can be used in a production line or a single machine. In the production line, it is often used in the filtration and impurity removal steps before the product is finely processed and before the packaging process after the product is processed, as a granular or powder product. Particle size inspection machine or work as a "quality inspector".

Sieve Industrial With belt conveyor

In order to meet the selection and use needs of different users in different industries, Dahan manufacturers support customization of supporting equipment according to user usage scenarios, such as: hopper type, gate type, mobile type, edged type and heightened sieve industrial equipment with different structures.