Before you spend time reading this page, I must say that this product (Soil Sieve) is more intended for use in the laboratory for soil sample analysis, although it can also handle your potting soil to a certain extent.

| Products | Chemical Powder Lab Standard Laboratory Particle Size Sieve for Sand 2mm soil sieve mesh screen |

| Material | Sus304, SS316Stainless steel, brass, or customized |

| Mesh count | Plain weave 1-635 mesh Dutch weave to 500 x 3500 mesh |

| Micron size | 1 micron - 2000 micron |

| Sizes | Diameter: 6 8 10 12 24 inches, 15cm 20cm 30cm 35cm 40mm or customized Height : 5mm, 8cm or customized |

| Features | Corrosion resistant, reusable, long use-life. Easy-clean |

| Applications | Lab/laboratory test sieve, sand, soil sieve and others |

1. The sieve hole is standardized, which is convenient for laboratory use and analysis

2. The Soil Sieve of the same model has a high degree of standardization and can be used nested

3. The large-diameter Soil Sieve screen surface is made of perforated plates, with uniform openings, stronger pressure bearing capacity, and longer service life

4. Easy to clean, high efficiency, high precision

For the laboratory, the Soil Sieve standard pore size and consistent nesting provide tool support for the analysis and detection of soil samples, determine the percentage of each particle size contained in the soil sample, and the test results can be used to generate soil particle size distribution curves.

| Type | Specifications |

| New standard sand sieve (φ300,7 pieces/set + bottom cover) | 9.50、4.75、2.36、1.18、600um、300um、150um |

| New standard stone screen (φ300 12 pieces/set + bottom cover) | 2.36、4.75、9.50、16.0、19.0、26.5、31.5、37.5、53.0、63.0、0.75、90.0mm |

| Road base aggregate screen (φ200, 300,11 / set + bottom cover) | 0.075、0.25、0.5、1、2、5、10、20、30、40、50mm |

| Drain the aggregate square sieve | 0.075、0.15、0.3、0.6、1.18、2.36、4.75、9.5、13.2、16、19、26.5、31.5、53mm |

| New standard square hole sieve (Φ200 ×50mm6 pieces/set) | Iron square hole:4.75、9.5、13.2、16、19、26.5、31.5、37.5、53mm Wire mesh square hole:0.075、0.15、0.3、0.6、1.18、2.36 |

| Blanking frame type sand screen (casting screen) φ200 (11 pieces/set) | 3.35、1.7、0.85、0.6、0.425、0.3、0.212、0.15、0.106、0.075、0.53mm |

| Pavement square hole aggregate screen | 80、60、50、40、30、25、20、10、5、2、1、0.5、0.2、0.075mm |

| Asphalt pavement aggregate screen (φ200, 300, 15 / set + bottom cover) | 0.075、0.15、0.3、0.6、1.18、2.36、4.75、9.5、13.2、16.0、19.0、26.5、31.5、37.5、53mm |

| Sand sieve Φ200 ×50(8 pieces/set) | Square hole copper mesh:2.5、1.25、0.63、0.315、0.16、0.08mm |

| Stone sieve Φ300 ×70mm (12 pieces/set) | 2.5、5、10、16、20、25、31.5、40、50、63、80、100mm |

| Lime screen (φ200 5 pieces/set + bottom cover) | 0.125、0.71、0.9、5、20mm |

| New standard pharmacopoeia sieve Φ 200×50mm (9 pieces/set) | 2、0.85、0.355、0.25、0.18、0.15、0.125、0.09、0、075mm |

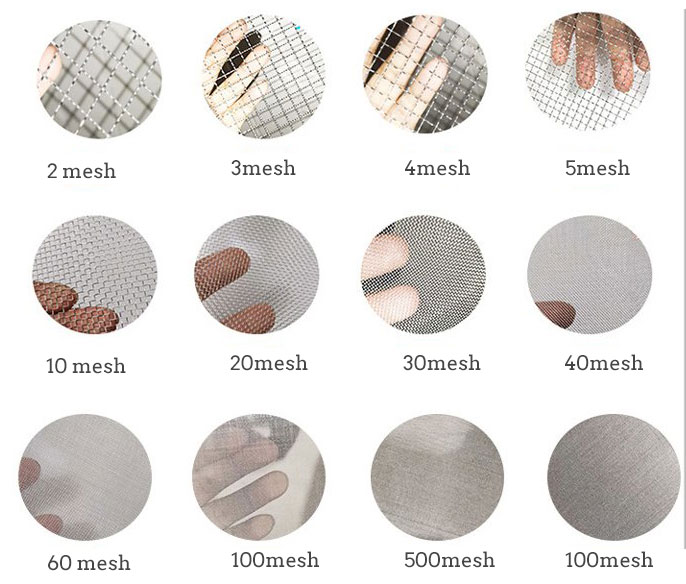

| Mesh | Aperture (mm) | Mesh | Aperture (mm) | Mesh | Aperture (mm) |

| 2 mesh | 12.5 | 45 mesh | 0.4 | 220 mesh | 0.065 |

| 3 mesh | 8 | 50 mesh | 0.355 | 240 mesh | 0.063 |

| 4 mesh | 6 | 55 mesh | 0.315 | 250 mesh | 0.061 |

| 5 mesh | 6 | 60 mesh | 0.28 | 280 mesh | 0.055 |

| 6 mesh | 4 | 65 mesh | 0.25 | 300 mesh | 0.050 |

| 8 mesh | 3 | 70 mesh | 0.224 | 320 mesh | 0.045 |

| 10 mesh | 2 | 75 mesh | 0.2 | 325 mesh | 0.043 |

| 12 mesh | 1.6 | 80 mesh | 0.18 | 340 mesh | 0.041 |

| 14 mesh | 1.43 | 90 mesh | 0.16 | 360 mesh | 0.040 |

| 16 mesh | 1.25 | 100 mesh | 0.154 | 400 mesh | 0.0385 |

| 18 mesh | 1 | 110 mesh | 0.15 | 500 mesh | 0.0308 |

| 20 mesh | 0.9 | 120 mesh | 0.125 | 600 mesh | 0.026 |

| 24 mesh | 0.8 | 130 mesh | 0.112 | 800 mesh | 0.022 |

| 26 mesh | 0.71 | 140 mesh | 0.105 | 900 mesh | 0.020 |

| 28 mesh | 0.68 | 150 mesh | 0.100 | 1000 mesh | 0.015 |

| 30 mesh | 0.6 | 160 mesh | 0.096 | 1800 mesh | 0.010 |

| 32 mesh | 0.58 | 180 mesh | 0.09 | 2000 mesh | 0.008 |

| 35 mesh | 0.50 | 190 mesh | 0.08 | 2300 mesh | 0.005 |

| 40 mesh | 0.45 | 200 mesh | 0.074 | 2800 mesh | 0.003 |

One, directly express the mesh size data

2. Mesh number: Mesh number refers to the number of holes and wires on a length of 1 inch 25.4 mm. Therefore, themesh number is a relative unit. There is a certain error relative to the direct expression of the mesh size. So ifyou have strict requirements on the mesh, you must Requires mesh size, not mesh

The following is a comparison table of mesh, wire diameter, and mesh

| Basic mesh size (mm) |

metallic line (mm) |

Screening area percentage (%) |

Net weight per unit area (kg/㎡) |

Equivalent mesh (M/inch) |

||||

| R10 | R20 | R40/3 | brass | Tin bronze | Stainless steel | |||

| 8 | 2.00 | 64 | 5.60 | 5.70 | 5.05 | 2.54 | ||

| 1.80 | 67 | 4.62 | 4.71 | 4.17 | 2.59 | |||

| 1.60 | 69 | 3.74 | 3.80 | 3.37 | 2.65 | |||

| 1.40 | 72 | *2.92 | 2.97 | *2.63 | 2.70 | |||

| 1.25 | 75 | 2.36 | 2.40 | 2.13 | 2.75 | |||

| 7.10 | 1.80 | 64 | 5.19 | 5.08 | 4.59 | 2.85 | ||

| 1.60 | 67 | 4.11 | 4.19 | 3.71 | 2.92 | |||

| 1.40 | 70 | *3.23 | 3.28 | *2.91 | 2.99 | |||

| 1.25 | 72 | 2.62 | 2.66 | 2.36 | 3.04 | |||

| 1.12 | 75 | 2.14 | 2.18 | 1.93 | 3.09 | |||

| 6.70 | 1.80 | 62 | 5.33 | 5.43 | 4.81 | 2.99 | ||

| 1.65 | 65 | 4.31 | 4.39 | 3.89 | 3.06 | |||

| 1.40 | 68 | 3.38 | 3.44 | 3.05 | 3.14 | |||

| 1.25 | 71 | *2.75 | 2.80 | *2.48 | 3.19 | |||

| 1.12 | 73 | 2.24 | 2.28 | 2.02 | 3.25 | |||

| 6.30 | 1.80 | 60 | 5.60 | 5.70 | 5.05 | 3.14 | ||

| 1.60 | 64 | 4.67 | 4.75 | 4.21 | 3.22 | |||

| 1.40 | 76 | 3.56 | 3.62 | 3.21 | 3.30 | |||

| 1.25 | 70 | *2.89 | 2.94 | *2.61 | 3.36 | |||

| 1.12 | 72 | 2.34 | 2.40 | 2.14 | 3.42 | |||

| 1.00 | 74 | 1.92 | 1.95 | 1.73 | 3.48 | |||

| 0.900 | 77 | 1.57 | 1.60 | 1.42 | 3.53 | |||

| 5.60 | 5.60 | 1.60 | 60 | 5.00 | 5.07 | 4.49 | 3.53 | |

| 1.40 | 64 | 3.91 | 3.98 | *3.53 | 3.63 | |||

| 1.25 | 67 | *3.19 | 3.25 | 2.88 | 3.71 | |||

| 1.12 | 69 | 2.62 | 2.66 | 2.36 | 3.78 | |||

| 1.00 | 72 | 2.12 | 2.15 | 1.91 | 3.85 | |||

| 0.900 | 74 | 1.74 | 1.77 | 1.57 | 3.91 | |||

laboratory test sieves for flour

laboratory sieve shaker for aggregate

How to use laboratory test sieves

1. Clean the Soil Sieve before soil sample analysis to ensure that the sieve surface is free from impurities, blockage and damage.

2. Weigh a representative dried soil sample.

3. Crush the soil sample into fine particles/powder using a mortar or soil pulverizer.

4. Weigh more than 500g of soil sample and set it as the total sample.

5. Stack the sieves according to the pore size of the Soil Sieve. The sieve with a large opening (small pore size) is placed above the small opening (large pore size), and the bottom end prevents the tray from collecting soil samples that pass through all the pore sizes, #4 and # A 200 sieve should always be included in the analysis of soil samples.

6. After placing the weighed 500g soil sample on the top of the Soil Sieve, place it on the laboratory vibrating sieve (all Soil Sieves stacked together), fix the sieve frame, set the analysis time, and start the machine.

7. After the machine stops running, take out the sieve frames one by one and weigh the weight of the soil sample retained in each sieve frame.

8. Carry out sample retention, data recording and analysis, and obtain the particle size distribution curve.