The high frequency vibrating sieve is the best choice for dealing with viscous or extremely cohesive slurry materials. It can be used to deal with liquids such as mud, ceramic glazes and milk for solid-liquid separation.

The biggest feature of high frequency vibrating sieve is that the 3000r/min high-frequency motor provides stronger vibration force for slurry filtration. The high-frequency vibration makes the viscous liquid quickly dispersed and difficult to aggregate and adhere, and improves the slurry and screen. contact area, so as to realize the separation of solid and liquid in the slurry and complete the filtration.

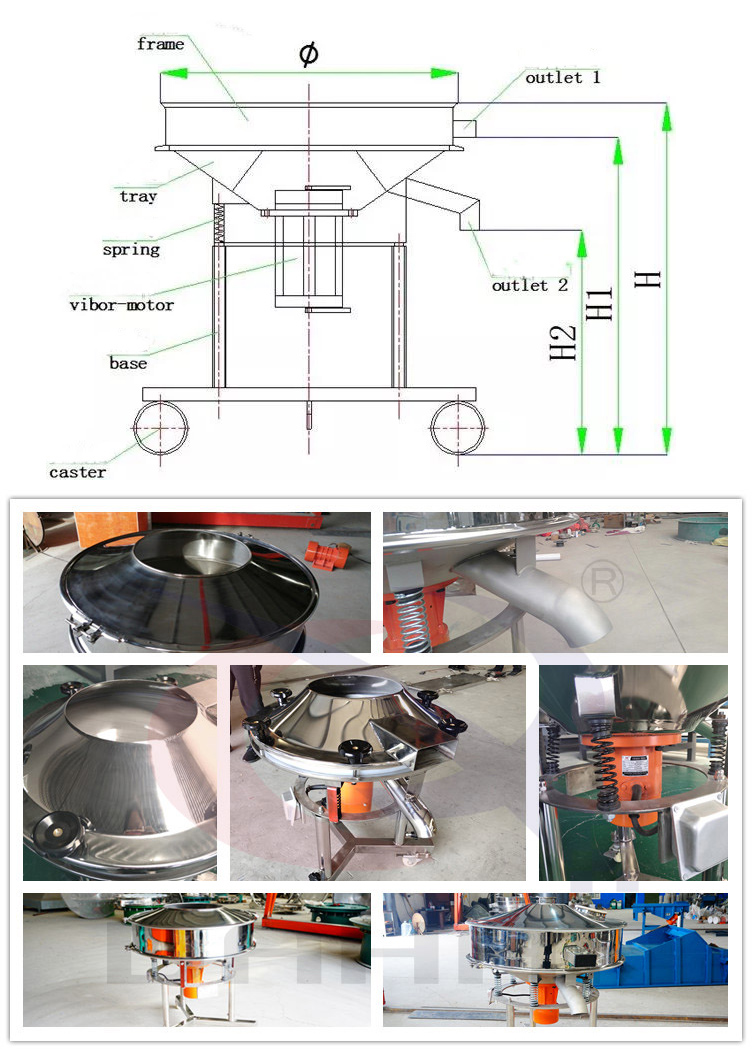

The high frequency vibrating sieve is a single-layer design, and the upper and lower layers of the sieve each have a discharge port, which is used to discharge the treated liquid and solid parts respectively.

Therefore, the single-layer structure design determines that the high frequency vibrating sieve only has the functions of solid-liquid separation and filtration and impurity removal.

Solid-liquid separation: It is used to realize solid-liquid separation of the processed paddle materials. The function of the screen is to separate liquid and solid, such as solid parts such as mud and stone particles in tailings, and the dehydration rate can reach 70%.

Filtration and impurity removal: It is used to separate liquids containing impurities or materials of two different particle sizes, such as removing unground beans from soy milk or milk skin formed after standing in milk.

high frequency vibrating sieve processing milk

high frequency vibrating sieve filter paint

1. High frequency, low amplitude, vibration frequency up to 3000 times/min, can effectively reduce the surface tension of the pulp, which is conducive to the separation and stratification of fine and heavy materials, and accelerates the passage of fine and heavy materials through the screen.

2. Using laminated screen, the single-layer aperture is increased, the life of the screen is increased, and it is anti-blocking and wear-resistant.

3. It can effectively deal with solid mixed materials, realize solid-liquid separation quickly, and the output is 2-5 times that of ordinary vibrating screen.

4. Rubber spring support screen frame, vibration isolation and sound absorption, low noise, small equipment load, no need for concrete foundation.

5. The heightened design of the upper frame can prevent the surface slurry from jumping during the filtration process.

6. The movable frame can be installed, which can be moved freely in the workplace, the height is adjustable, the installation is not complicated, the operation is simple, and it is not easy to damage

7. The unique screen structure prolongs the service life by 2 to 3 times, and it is convenient and simple to change the screen, and it only takes 3-5 minutes to replace once.

| Model No. | effective sieve plate diameter(mm) | Powder(KW) | Voltage | Vibration Force | Rotor Speed(r/min) |

| DH-600 | 550 | 0.55 | 380 | 8000N | 3000 |

| DH-800 | 760 | 0.75 | 380 | 10000N | 3000 |

| DH-1000 | 930 | 1.10 | 380 | 15000N | 3000 |

| DH-1200 | 1130 | 1.50 | 380 | 20000N | 3000 |

High frequency vibrating screens are widely used in mining, building materials, chemicals, food, pharmaceuticals, environmental protection, metallurgy, agriculture, electronics and water treatment industries due to their high-efficiency screening and strong dehydration capabilities. Their high-frequency vibration characteristics ensure efficient screening effects and meet the needs of different industries for fine screening and high-efficiency screening.

| Materials | Density (kg/m3) |

Mesh size (mm) |

Model | Processing capacity (L/h) |

| grape juice | 1 | 0.1 | GPS800 | 1000 |

| wine | 1 | 0.05 | 800 | |

| yeast | 0.5 | 0.5 | 6000 | |

| Orange juice | 1 | 1 | 1500 | |

| soy sauce | 1 | 0.15 | 4000 | |

| Ceramic Slurry | 1 | 0.028 | 800 | |

| coating | 1.2 | 0.045 | 3000 |

High frequency vibrating sieve is mainly used in solid-liquid screening and filtration in the ceramic industry (mud, glaze), paint industry, coating industry, and other industries, especially in the ceramic industry for the screening and filtration of glazes. A high-frequency screen with a diameter of 600 and a 120-mesh screen can filter 2-3 tons of glaze in one hour.

| main point | high frequency vibrating sieve | vibrating sieve |

| Motor speed | 3000r/min | 1500r/min |

| layers | Only 1 layer of screen | 1-5 layers of screen can be designed |

| structure appearance | The single-layer design has two outlets, which can be automatically discharged | 1-5 layers are designed with 2-6 outlets, which can be automatically discharged |

| handling materials | Viscous grout (paint, mud, etc.), or other liquid | Granules, powders, liquids within 500 mesh, almost unlimited |

| processing power | 200-1200 liters/hour | 100-3300kg/h |

| Purpose | Filter and remove impurities from the liquid, which is very advantageous when dealing with viscous slurries | Grade separation or impurity removal and filtration for particles, powders, and liquid materials |

1. High frequency vibrating sieve is suitable for handling materials with high viscosity and less impurities; ordinary vibrating sieve is suitable for handling dry powder particles and thin liquids, and is easy to filter or remove impurities.

2. The high frequency vibrating sieve rate is increased from the original 1440r/min to 3000r/min, so the vibration frequency is high, and the screen is not easy to block. The motor used for ordinary vibration screening is a 4-level vertical vibration motor, and the motor speed is only 1500r/ min.

3. The high frequency vibrating sieve is only used for filtering and removing impurities. In addition to removing impurities, ordinary vibrating sieves can also be used for screening.

Classification by vibration mode

| Type | Picture | Features | Applicable industries |

| Linear high-frequency vibrating screen |  |

Linear motion trajectory, high screening accuracy, suitable for dry screening | Mining, building materials, chemical industry, food, metallurgy |

| Circular high frequency vibrating screen |  |

The track is circular or elliptical, suitable for wet or sticky materials | mines, building materials, sand and gravel, coal |

| Rotary vibration high frequency vibrating screen |  |

Three-dimensional vibration motion, suitable for ultra-fine powder and high-precision screening | food, medicine, chemical industry, metallurgy, ceramics |

Classification by structural form

Single-layer high-frequency vibrating screen: single-layer screen, suitable for screening single-specification materials, suitable for powder processing, mining, food, and building materials industries

Multi-layer high-frequency vibrating screen: can be installed with 2-5 layers of screens, multi-level screening, improve production efficiency, suitable for metallurgy, chemical industry, food, medicine, and construction industries

Fine screening: Separate fine particles of 0.074-10mm with an accuracy error of ≤5%, avoiding the blockage problem of traditional screening equipment.

Dehydration and de-mediuming:Accelerate the separation of moisture or medium (such as magnetic powder in heavy medium beneficiation) on the surface of the material through high-frequency vibration, thereby improving the efficiency of solid-liquid separation.

Adapt to complex materials:Handle high-concentration viscous liquids, wet and sticky materials, and easily agglomerated powders, destroy the surface tension of the material, and improve the screening efficiency.

| Model | PH-1500 |

| Voltage | 220V/380V |

| Power | 1500W |

| Material | 304 Stainless steel |

| Production efficiency | 500-1000kg/h |

| Sieve diameter | 500mm(600/800mm, it can be customized) |

| Sieve height | 160mm |

High-frequency vibrating screen is a professional equipment designed for handling high-viscosity fluids and solid-liquid separation of thick slurry materials.

Dahan Machinery has been deeply involved in the field of fine screening. With its excellent performance, it has served the German and other European markets, covering countries such as Vietnam and Singapore, and continues to expand to more regions around the world, helping customers achieve efficient production with reliable quality.