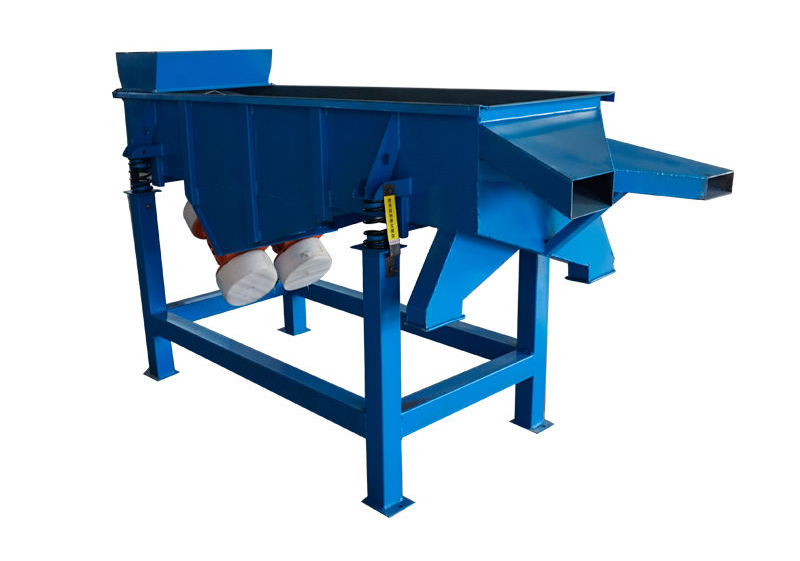

carbon steel:

The common Linear Vibrating Screen material is used for the screening of most scenes and materials. It is sturdy and durable, with low price and no special properties.

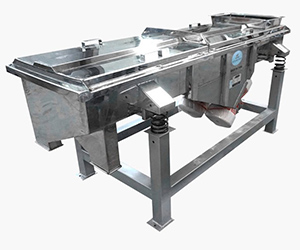

Stainless steel:

Made of 304 or 316L stainless steel, it is safe and non-toxic, resistant to acid and alkali corrosion, and does not rust.

Linear Vibrating Screen is suitable for non-viscous dry powder and particle screening and classification with moisture content less than 7%. It is driven by dual motors, which can make the material move linearly on the screen surface to complete the screening and removal of impurities. The screening efficiency is as high as 96%, and the consumption can be reduced by 30%.

1. 0.12-20 tons/hour large output screening and impurity removal.

2. It can be sieved as fine as 400 meshes, and the best effect is below 200 meshes.

3. Fully sealed design to avoid waste and pollution.

4. The 1-6 layers are effectively screened, and the materials are separated in 2-7 specifications.

5. The fixed structure of the screen box is easy to disassemble, which can easily replace accessories and maintain.

6. Automatic feeding and discharging, uninterrupted continuous production, reduce labor costs.

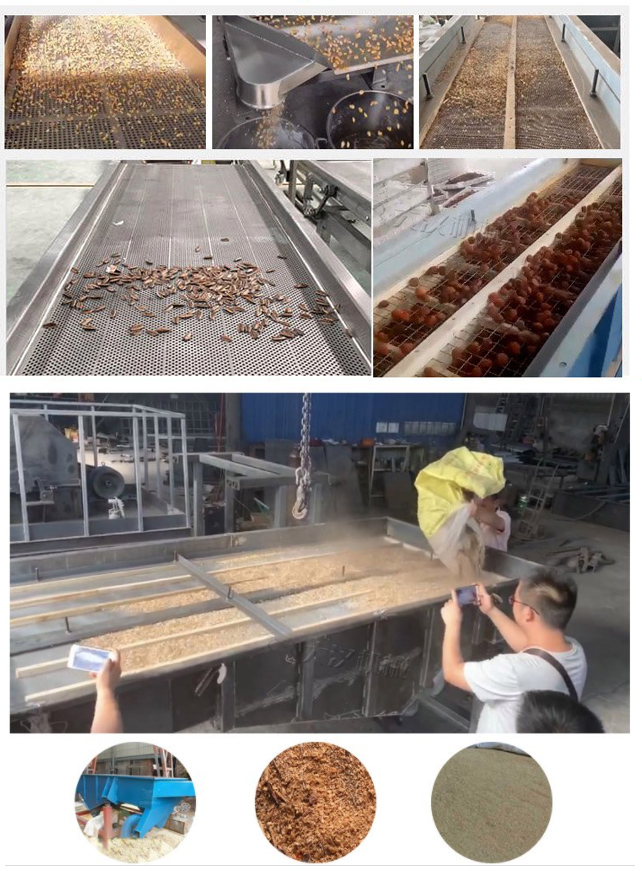

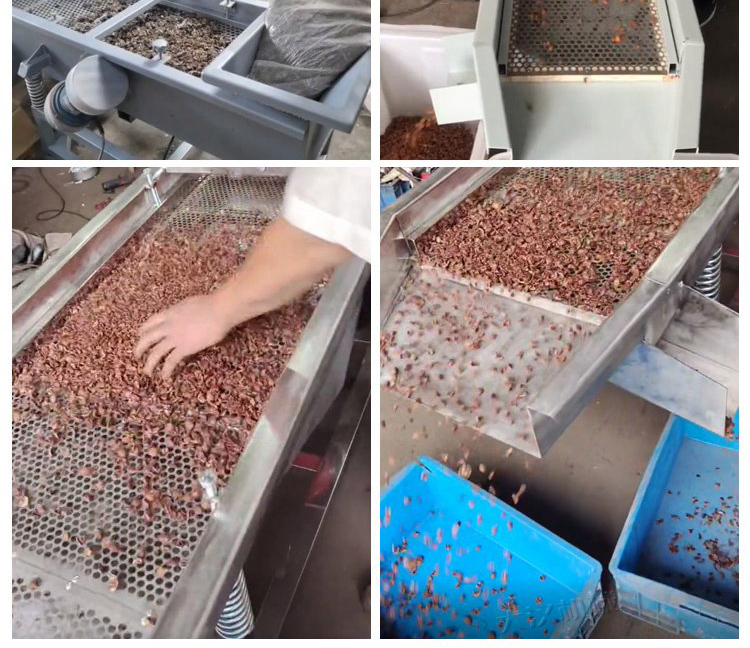

Stainless Steel Linear Vibrating Screen Screens Plastic Particles

Linear Vibrating Screen for sieving herbs

Oversized Linear Vibrating Screen for sand screening

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

| Name | Image | Features |

| Ordinary linear vibrating screen |  |

Suitable for handling a wide range of dry powders and granules |

| Air-cooled linear vibrating screen |  |

It is suitable for high temperature materials and can be screened after effectively reducing the temperature of the materials. |

| Adjustable Linear Vibrating Screen |  |

Adjust the angle and height of the linear vibrating screen according to the material screening process. |

| Suspended linear vibrating screen |  |

The screening equipment that can be installed in the air can save space on the screening site |

| Silo type linear vibrating screen |  |

Equipped with a feeding bin, the feeding speed can be controlled by adjusting the feeding bin insert. |

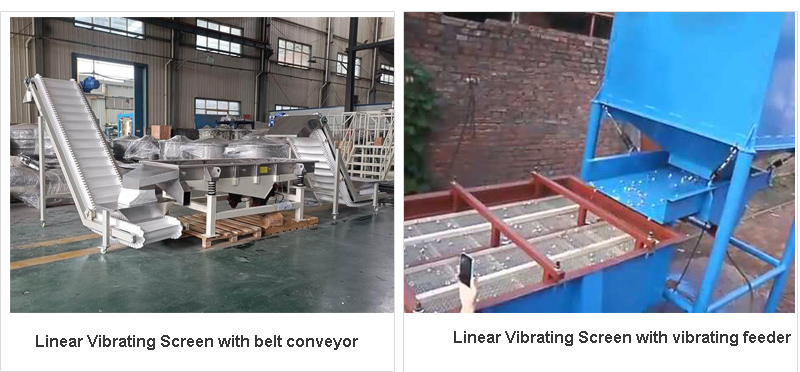

Linear vibrating screen has a wide range of application scenarios. In addition to food, plastic, abrasive, chemical, pharmaceutical, building materials, grain, carbon, fertilizer and other industries, it can also be used in the production line of various materials for screening or impurity removal. It can cooperate with the original upper and lower end feeding and processing machines (conveying equipment, lifting equipment, feeder, etc.), saving time, manpower and cost.

Grain food screening

Sand and gravel screening

Fertilizer feed screening