1. Effectively imitate the manual screening action and process, and the screening accuracy is as high as 90-95%;

2. The running track of the material screen surface is softer, the impact force is reduced, the damage to the screen is greatly reduced, and the maintenance cost of the machine is reduced.

3. A variety of screen cleaning devices can be added (such as: bouncing ball to clean the screen surface, ultrasonic technology to clean the screen surface, etc.), which can effectively solve the problem of screen surface blockage, ensure the continuity of screening, fully enclosed structure, and reduce environmental pollution ;

4. The discharge port can be rotated 360 degrees at will, and it is easy to disassemble and assemble;

5. Low noise, the noise can be as low as 75dBa;

6. Compared with traditional screening equipment such as rotary vibrating screen and linear screen, the processing capacity per unit area can reach up to 5 times, especially suitable for difficult materials.

Screening pollen

Sieving stainless steel powder

Screening flour

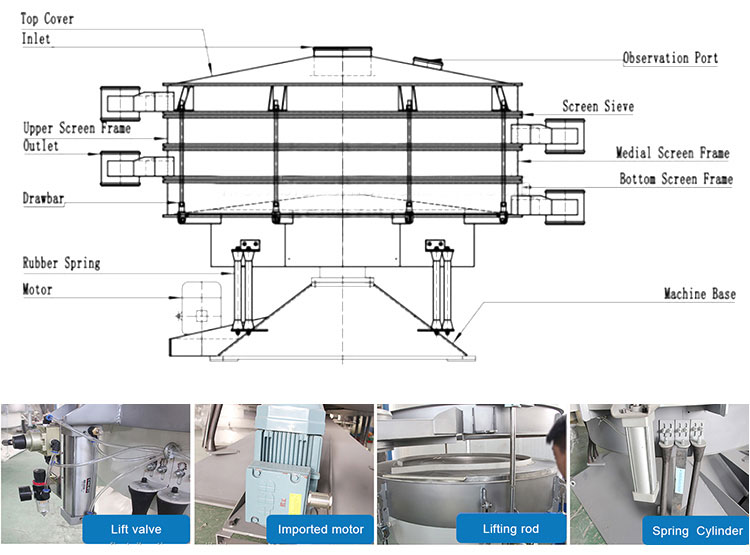

The Tumbler Screen generates power through a vibrating motor. The motor drives the main shaft and the eccentric block on the main shaft to rotate. The eccentric block drives the upper box to make the whole machine work by imitating the action of manual screening. The spring group controls the swing amplitude and acceleration of the screen box. The power group Cooperate with each other to effectively screen materials.

| Model | Diameter(mm) | The area of screen(㎡) | The angle of screen surface(。) | Layer(s) | Power(kw) |

| YBS-600 | 600 | 0.21 | 0-10 | According to customer's demand | 0.25 |

| YBS-1000 | 1000 | 0.66 | 1.5 | ||

| YBS-1200 | 1200 | 0.98 | 2.2 | ||

| YBS-1600 | 1600 | 1.81 | 4 | ||

| YBS-2000 | 2000 | 2.80 | 4 | ||

| YBS-2400 | 2400 | 4.15 | 5.5 | ||

| YBS-2600 | 2600 | 5.31 | 5.5 |

1. The direct-connected vibrating device is different from the ordinary vibrating screen. This device is connected to the motor and the transmission device through a belt, and through the reverse movement of the motor, the screen frame is put into artificial "dusting" and "kips" when passing through the transmission device. The screening is soft and does not damage the shape and characteristics of the material.

2. The design of the screen mesh prolongs the screening diameter and prolongs the residence time of the material on the screen surface, thereby improving the screening efficiency and accuracy. Compared with the ordinary vibrating screen, the screening efficiency is increased by 1-5 times, and the accuracy is increased by 90%. %-99%.

3. The mesh frame adopts a one-time forming punching design, and a trawl plate is designed in the middle to ensure that the screen mesh bears evenly and achieves the purpose of improving the service life of the screen mesh.

4. There are three kinds of net cleaning devices, namely: bouncing ball net cleaning device, rotary brush net cleaning device, and ultrasonic net cleaning device, to ensure that the screen holes will not be blocked, and users can choose according to their own needs.

5. The vibration motor is installed on the outside of the screen machine, which is more convenient for maintenance and repair in the later period.

Tumbler Screen can upgrade the design of the product according to the actual use needs, so as to achieve the expected screening effect of more special occasions or special materials. The more common customizations of Tumbler Screen are as follows:

Machine surface treatment to suit different applications or application needs, such as polishing, brushing, sandblasting, painting, spraying special coatings, etc.

The addition of an ultrasonic system further improves the ability of the Tumbler Screen to handle fine powders. The high-frequency and low-amplitude vibration can keep the thin powders in a low-altitude suspension state during the sieving process. The powders are easier to disperse and pass through the screen faster, and it is not easy to generate static electricity. To a large extent, it also avoids the situation that the material clogs the screen.

Increase the design of the hopper to increase the feeding amount of materials received by the Tumbler Screen, so that the Tumbler Screen can be used with more feeding equipment, such as screw feeders, belt conveyors, and silos. The lower end of the hopper is usually equipped with an adjustable butterfly valve, which can adjust the flow of the material entering the Tumbler Screen from the hopper according to the actual feeding needs.

The Tumbler Screen is used in the chemical and food industries to produce high-quality powders with sensitive properties; the technology also allows gentle handling of powders. The technology can also be used as an efficient method for recycling high-quality raw materials.

In food processing, use a simpler single-layer Tumbler Screen with a screen size of 1 to 4 mm to remove foreign matter and ensure product safety.

This technology is also applied in metallurgy and ceramic industry, and can be used to process ceramic particles, refractory materials, etc.

1. Rotary screening: Two layers of screens with the same aperture allow the materials that have been screened once to be screened again to achieve higher screening accuracy.

2. Rotary reverse sieving: the material is sieved from fine → medium fine → medium → coarse, and the coarse material plays a certain role in cleaning the mesh.

3. Double treatment and screening: The materials entering the sieve machine are evenly distributed to two levels, so that the processing capacity of a single sieve machine is nearly doubled, and one sieve machine can be used as two.

4. Combined screening: ordinary screening + rotary screening, improving the utilization rate of a single screening machine.

Tumbler Screen is used for: sugar, sawdust, graphite, ceramic powder, polyvinyl alcohol, corn, calcium dioxide,abrasive, flour, tea, feed, plastic, rubber, fertilizer and other materials.

| Tumbler Screen material application classification display | ||

|

Particles: | Oat kernel 14 mesh, cassia seed 16 mesh, corn chopped 16 mesh, rice 12-14 mesh, black bean 5 mesh, red bean 5 mesh, soybean 6 mesh, barley 8 mesh mung bean 10 mesh, buckwheat 12 mesh, black rice 14 mesh, brown rice 14 Mesh, sesame 24 mesh, millet 24 mesh |

|

Powder category: | Traditional Chinese medicine powder is generally 60 mesh, coarser 40 mesh, oral 60-80 mesh, fine Chinese medicine mask 100-120 mesh, fried chicken powder 10-30 mesh, corn flour 30 mesh, almond powder 30-40 mesh, flour 50-60 Item, Rice roll 60 mesh, whole grains 30-40 mesh, Panax notoginseng powder 80-100 mesh, pearl powder 120-150 mesh, pine pollen 80-120 mesh, coffee powder 100-120 mesh |

|

Liquid category: | Filter soybean milk, honey 60-120 mesh, filter medicine residue, soup residue, tea water 80-150 mesh |

|

other: | Pepper 6 mesh, insect dung screen 30 mesh, cat litter 30-40 mesh, butterfly noodle 50 mesh, pepper seed 8-10 mesh, sand painting 80-120 mesh, edible oil, mechanical oil residue 150-200 mesh, yellow mealworm production Egg sieve 12 mesh |

Tumbler Screen imitates manual sieving with gentle operation, more suitable for handling fragile crystalline particles, and can ensure the integrity of materials to the greatest extent. The screening efficiency is generally 93%~95%. A cleaning device will be placed between the screen layers. The output of tumbler sieve is about 6~60t/h. The output will vary according to different materials. The screening of materials below 600 mesh has obvious advantages .

| Classification | Tumbler screen | Vibro Sifter |

| principle | Imitating manual screening, the material does non-linear three-dimensional motion on the sieve surface | Three-dimensional vibration screening |

| Screening capacity | 1-10 tons/hour | Horizontal, inclined, vertical three-dimensional motion |

| materials | fine powder, brittle crystalline particles | Granules, powders, liquids |

| Yield | 5-10 times the yield of the Vibro Sifter | 100-3300kg/h/td> |

| price | higher | Low |

1. Bouncing ball cleaning net: most granular materials

The bouncing ball is installed between the perforated plate and the grid, and the power of the Tumbler Screen makes the bouncing ball continuously hit the grid to clear the net

Applicable to the cleaning of rice, medicine, quartz sand, etc.

2. Ultrasonic deblinding: easy to agglomerate, hold groups, strong adsorption ultrafine powder

The ultrasonic deblinding method can suspend the materials attached to the surface of the screen, thereby inhibiting the blocking factors such as adhesion, friction, and flat drop;

Applicable to the cleaning of flour, coffee powder, wood chips, aluminum oxide, etc.

3. Drum brush device: spherical, crystalline and brittle materials

The drum brush relies on the rotation of the brush arranged under the screen to clean the Tumbler Screen

It is suitable for cleaning nets of chicken bouillon, table salt, PVC (polyvinyl chloride) plastics, etc.