Gas protection vibrating screen

Gas protection vibrating screen is a high-precision fine powder screening machine with low noise and high efficiency. In order to process some materials with special properties, a gas protection device is added to process powder materials in a sealed environment without air isolation. Inert gas can be filled according to material properties.

1. Flange design at the feeding port, connected with the upper machine, automatic screening;

2. Install inert gas protection system to avoid deterioration of active materials;

3. The fully sealed screen machine avoids material exposure to air while reducing dust and waste;

4. The ultrasonic system is installed to realize ultrafine powder screening and automatic net cleaning.

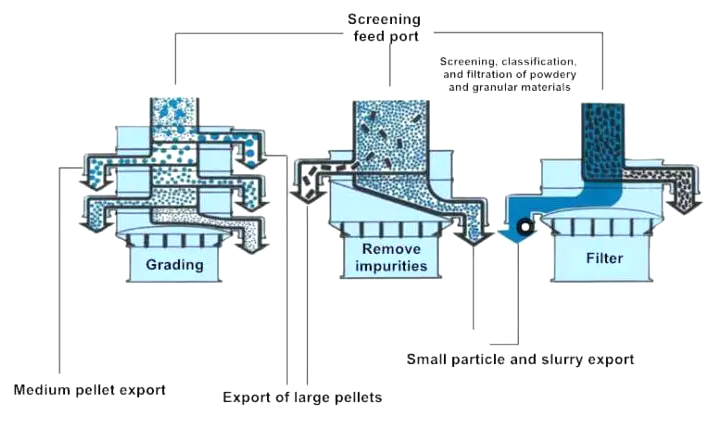

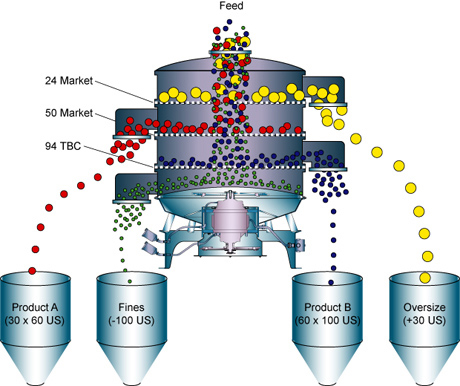

The gas protection vibrating screen is equipped with a gas protection device. The part in contact with the material is made of 304 material. The vertical vibration motor is used as the excitation source, which can generate three-dimensional movements of horizontal, vertical and inclined. When the movement track is transmitted to the screen surface, it is larger than the screen hole The material with the largest size remains on the screen surface and is discharged from the coarse material discharge port, and the material smaller than the size of the sieve hole falls into the lower layer.

Gas protection vibrating screen is extremely suitable for the screening of fine, sensitive and reactive powder materials, and can also be used for the screening of some granular materials. It is widely used in metal powder, alloy powder, stainless steel powder, aluminum powder, silicon powder, graphite powder, tungsten powder. Screening of new materials such as powder and 3D printing materials.

Gas protection vibrating screens are installed for the characteristics of certain materials, such as some materials cannot be exposed to oxygen, carbon dioxide, etc. Gas protection vibrating screens are highly efficient, compact and durable in design, meshes are not blocked, there is no flying powder, impurities and coarse materials are automatically discharged, and they can run continuously. High efficiency, exquisite and durable design, can screen powders and mucus.

| Model | Screen Diameter (mm) |

Sieving Area (m2) |

Screen Size (mesh) |

Layers | Power (KW) |

| DHC-400 | 340 | 0.091 | 80-600 | 1~3 | 0.18 |

| DHC-600 | 540 | 0.229 | 0.25 | ||

| DHC-800 | 730 | 0.418 | 0.55 | ||

| DHC-1000 | 900 | 0.636 | 0.75 | ||

| DHC-1200 | 1100 | 0.95 | 1.1 | ||

| DHC-1500 | 1400 | 1.539 | 1.5 | ||

| DHC-1800 | 1700 | 2.269 | 2.2 | ||

| DHC-2000 | 1886 | 2.792 | 2.2 |

| Vibrating screen type | picture | working principle | main features | applicable scenarios |

| Ultrasonic vibrating screen |  |

On the basis of traditional vibrating screen, high-frequency and low-amplitude ultrasonic waves are superimposed to destroy the surface tension of the material | High screening accuracy, which can effectively solve the screening problems such as strong adsorption and easy agglomeration | fine powder, medicine, food, chemical industry and other industries with high screening accuracy requirements |

| Gas protection screen |  |

Introduce inert gas during the screening process to prevent the material from contacting with the air and avoid risks such as oxidation | High safety, which can effectively protect the properties of special materials | Screening of special materials such as flammable, explosive, oxidizable, toxic and harmful |

| Linear vibrating screen |  |

Using dual exciter drive, the screen body makes reciprocating motion in a straight line, and the material jumps forward on the screen surface | Large processing capacity and high screening efficiency | Coarse, medium and fine particle screening of large-volume materials such as mines, coal, building materials, and grain |

| Scope of application | Description |

| Flammable and explosive materials | Applicable to flammable and explosive materials, protected by inert gasto prevent combustion or explosion. |

| High-purity materials | Applicable to materials that need to maintain high purity to prevent contamination during the screening process. |

| Special chemicals | Applicable to chemicals that are sensitive to oxygen or moisture to ensure that they remain stable during the screening process. |

| Pharmaceutical and food industries | Applicable to the screening of materials that require strict environmental control in the pharmaceutical and food industries to ensure product safety and quality. |

At this stage, metal 3D printing has completed the development of large-scale equipment, and many printing service providers have begun to deploy large-scale equipment in batches. While using high-capacity milling equipment, stable and efficient classification of the produced powder is also required.

However, 3D printing powders are light, fine and some have special properties, which puts forward higher requirements for the use of screening equipment.

The screen surface of common screening equipment is a metal wire woven screen, which can distinguish powders of different particle sizes through its fixed aperture. However, the static powder is easy to get stuck in the screen holes. The ultrasonic device of the Gas protection vibrating screen can provide the function of cleaning the screen and solve the problem of blocking the screen.

3D printing powder needs to use airflow classification, and for more active metals such as titanium alloys and aluminum alloys, it is necessary to use inert gas circulating airflow to prevent their properties from changing, so Gas protection vibrating screen is an excellent choice.

20-100 mesh: suitable for screening materials with coarse particles, such as certain metal powders, chemical raw materials, etc.

100-200 mesh: suitable for screening materials with medium particle size, such as fine chemical products, food additives, etc.

200-400 mesh: suitable for screening finer materials, such as high-purity metal powders, pharmaceutical intermediates, etc.

400 mesh and above: suitable for screening extremely fine materials, such as nanomaterials, high-precision ceramic powders, etc.