Standard Test Sieve is a screening equipment commonly used in experiments, which can be used manually or with machines, saving the trouble of manual operation.

Standard Test Sieve has strict requirements on accuracy and conforms to ISO3310-1:1990R20/3, R20, R40/3 series standards. There are 37 Standard Test Sieves in the whole set. The Standard Test Sieve of the same model ensures accurate nesting and can meet the Analysis standard for experimental samples.

Standard Test Sieve

A test sieve specially designed for Standard Test Sieve. It has an automatic timing function of 0-99 minutes. It can set the same screening time for the same material as needed to ensure the uniformity of sample analysis data. Reduce inspection errors.

1. According to the material

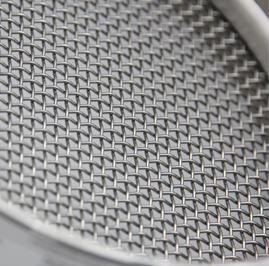

Stainless Steel Standard Test Sieve:

Common Standard Test Sieve material, resistant to wear and corrosion, no rust, and high hygiene standards.

Brass Standard Test Sieve:

It has good ductility and is used for special sample screening. It is softer than stainless steel.

Nylon Standard Test Sieve:

Non-magnetic material and metal material, used for sieving of special fibers, chemical additives and samples with active properties.

2. According to the screen

Metal braided wire mesh:

The finer mesh type is mostly made of metal wire, the hole type is square, and the mesh number is 0.02mm-2.36mm.

Punching plate screen:

Most of them are punched from stainless steel. The mesh shape is round or square, and the shape can be customized. It is mostly used for soil, sand and other hard, granular or block samples.

Electroforming screen:

The most dense form of sieve mesh, the mesh number is 75μm-5μm, which needs to be supported by a mesh frame, which is suitable for sieving light, fine and small samples.

Divided by purpose:

| Screening type | Picture | applicable materials | features | applicable industries |

| Sonic sieve |  |

Ultrasonic powders, easily agglomerated materials | Applicable to ultrafine powders (20μm-300μm) Prevent clogging and improve screening efficiency |

Pharmaceuticals, chemicals, metallurgy, food |

| Standard sieve |  |

Various powders and particles | Classic test sieve, commonly used for particle size analysis Mesh number standardization |

building materials, geology, food, medicine, chemical industry |

| Wet washing screen |  |

viscous powder, easy-to-block particles | Suitable for fine particles Combined with water flow to reduce screen blockage |

environmental monitoring, mining, ceramics, chemical industry |

| Airflow screening instrument |  |

light powder, ultrafine powder | Suitable for low-density, fine-particle powder High precision, fast screening speed |

food, medicine, powder materials, metallurgy |

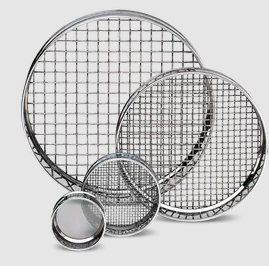

Weaving mesh sieve

Frame diameter: ø 200/203 millimeters (8 inches)

Surface type: metal mesh Grid size: 125mm -20mm Standard: ISO 3310-1 / ASTM E11

Weaving wire mesh sieve>

Frame diameter: ø 100/305/400/450 millimeters Surface type: metal mesh Grid size: 125mm -20mm Standard: ISO 3310-1/ASTM E11

Perforated plate sieve

Frame diameter: ø 200/305/400mm Surface type: perforated plate Aperture size: 125mm -1mm Standard: ISO 3310-2/ISO 5223

1. The mesh surface is smooth and smooth, the sample flows freely, and the effect is good;

2. High-quality materials are not easy to wear and corrode, and do not contaminate samples;

3. The screen is edged and polished to be smooth and not easy to cause damage;

4. The mesh is uniform and the aperture is accurate to ensure the accuracy of analysis;

5. ISO standard Standard Test Sieve, the same type of products can ensure consistent nesting.

| Model | The mesh size(mm) | Texture |

| Φ200X50 | 0.500 | Stainless steel/brass/nylon mesh |

| Φ200X50 | 0.600 | |

| Φ300X65 | 0.500 | |

| Φ300X65 | 0.600 | |

| Φ400X85 | 0.500 | |

| Φ400X85 | 0.600 |

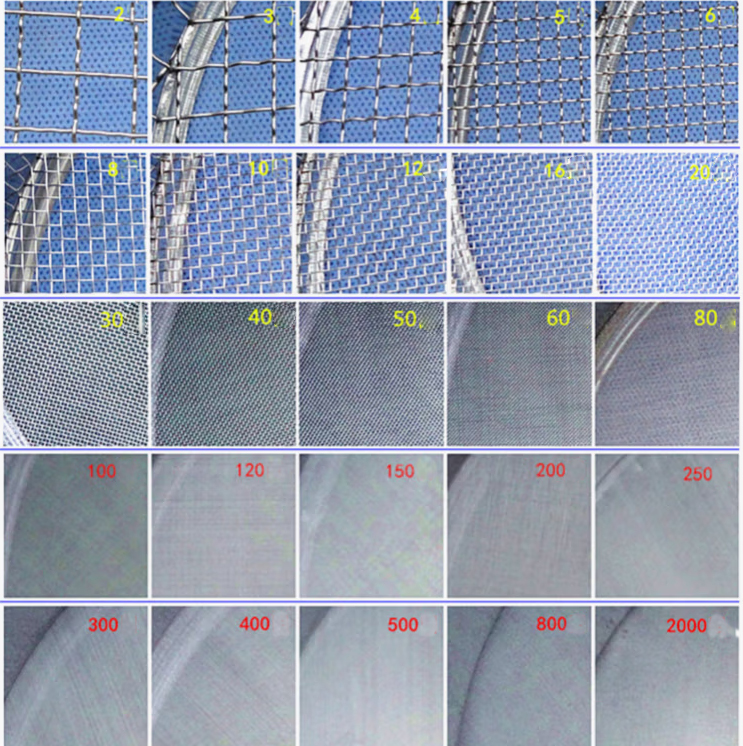

| No. | Type | Mash(mm) | No. | Type | Mash(mm) |

| 1 | 8# | 2.360 | 17 | 100# | 0.150 |

| 2 | 11# | 2.000 | 18 | 120# | 0.125 |

| 3 | 12# | 1.700 | 19 | 140# | 0.106 |

| 4 | 14# | 1.400 | 20 | 170# | 0.09 |

| 5 | 16# | 1.180 | 21 | 200# | 0.075 |

| 6 | 18# | 1.000 | 22 | 230# | 0.063 |

| 7 | 20# | 1.850 | 23 | 270# | 0.053 |

| 8 | 25# | 0.710 | 24 | 325# | 0.045 |

| 9 | 30# | 0.600 | 25 | 400# | 0.038 |

| 10 | 35# | 0.500 | 26 | 500# | 0.028 |

| 11 | 40# | 0.425 | 27 | 635# | 0.020 |

| 12 | 45# | 0.355 | 28 | 700# | 0.018 |

| 13 | 50# | 0.300 | 29 | 800# | 0.015 |

| 14 | 60# | 0.250 | 30 | 1000# | 0.01 |

| 15 | 70# | 0.180 | 31 | 1250# | 0.005 |

| 16 | 80# | 0.180 | 32 | 1800# | 0.003 |

Standard Test Sieve is widely used for accurate screening and particle size detection of granular materials in the experimental process of abrasives, geology, metallurgy, pharmacopoeia, chemical building materials, etc. It is suitable for screening a small amount of samples.

Applications: Particle Size Distribution Analysis, Sample Preparation, Fractionation

Material to be Sieved: Powders, Aggregates, Suspensions, Seeds, etc.

Industrial Areas: Agriculture, Construction (Building & Road Construction), Environmental Technology, Food Industry, Geology, Medicine & Pharma, Metallurgy

Tailored test screens for various applications, with tolerances that meet or exceed ordinary screen standards, providing detailed certification consistent with the given tolerances

Do you face screening tasks or other analytical issues that require the use of uncommon or luxurious screen sizes that cannot be found in any typical screening criteria?

Through our unique customization service, we can achieve single piece or small batch production of any perforated pattern: any perforated pattern, any board thickness, customized board material, any hole spacing and tolerance, all meet customer specifications.

Technical specifications:

Available screen types: circular holes (Rg, Rv, RdV), slotted holes (Lg, Lv, Lvc), square holes (Qg, Qv, Qdv), triangular holes, hexagonal holes (Hc), etc.

Aperture width: starting from 2.00 millimeters

Standard tolerance for aperture width: ± 0.05 millimeters

High quality manufacturing, reliable results: The accuracy of the standard test sieves depends on the manufacturing process used. The sieve measurement of Dahan Machinery is accurate and consistent.

Multiple alloys can achieve seamless integration: the alloy of tstandard test sieve determines its performance. Choosing appropriate materials can ensure the required durability, chemical resistance, and accuracy.

Meet the precision required for your process: Each laboratory has different requirements for precision. Understand the functions of the matching sieve, standard test sieve, and gold test sieve to best meet your accuracy requirements.