Sieve shaker

Features: Driven by electric motor, suitable for dry and wet sieves, equipped with 0 – 99 minutes timer, power meter for adjusting vibration speed and main switch.

Application: It is used in various laboratories, laboratories, article screening, screening, grading and other inspection departments.

Ultrasonic sieve shaker

FeaturesThe fine powder classification and filtration equipment developed on the basis of standard sieve shaker solves the problem of mesh blockage.

ApplicationIt is a common inspection equipment for mesh clogging when the laboratory is doing fine powder sample screening.

Electromagnetic sieve shaker

Features:Driven by electromagnetism, it can sieve to 20um (635 mesh): the negative pressure device designed by our company is added, which can sieve and screen materials 5μm.

Application: Inspection and particle size analysis of solids, powders, slurry materials and other materials.

Rotap sieve shaker

FeaturesIt has two vibrations of flapping and reciprocating at the same time, and the material is unloaded quickly and the material is not easy to be blocked.

ApplicationAbrasive particle size composition inspection, superhard material production classification and particle size composition inspection

1. Accurate, repeatable screening results

Sieving sample volumes up to 2kg and measuring ranges from 5μm to 63mm, ideal for quantitative particle size analysis of various solids and suspensions by dry or wet sieving using braided test sieves or micro-precision sieving.

2. SUS304 stainless steel

The screen frame is made of SUS304 stainless steel by stretching and polishing, with a wall thickness of 0.6mm, uniform luster, durable and non-magnetic.

3. High temperature resistance

The screen mesh and the screen frame are fixed by welding to prevent loosening and shaking, and can work stably at temperatures >300 degrees.

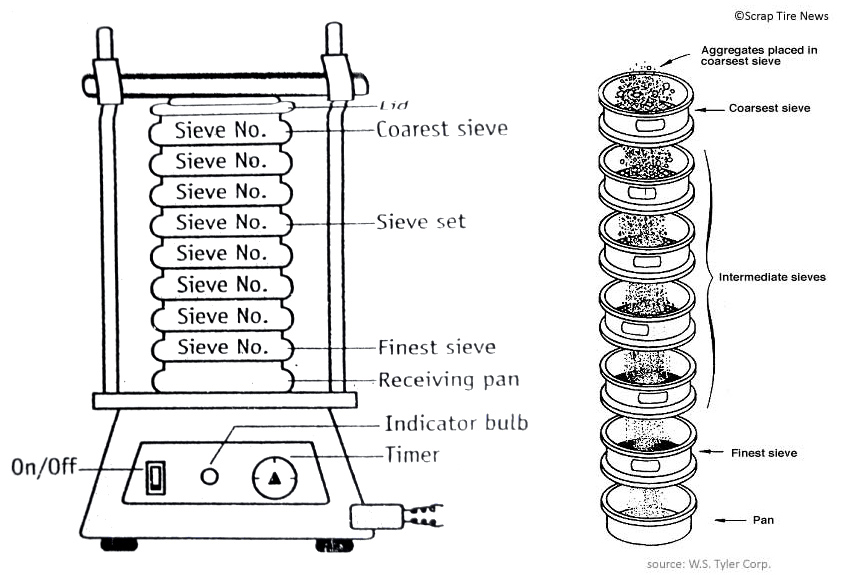

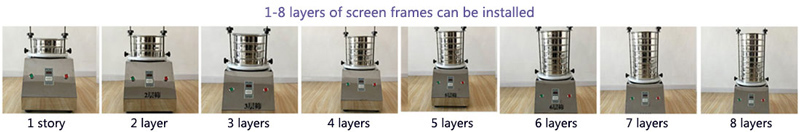

4. Multi-layer classification

The industrial sieve shaker can place 8 sieves (including receiving trays), which can accurately separate 2-9 different particle segments from 1 material at the same time.

5. 0-99 minutes customization function

The equipment is equipped with a timer, which can be shut down regularly to ensure the consistency of each production or test.

6. Not easy to block

The unit features a triple vertical-lateral-rotational vibration action that moves the sample through the sieve, resulting in faster, more efficient sieving, while the fast vertical motion also helps prevent hole clogging.

Industrial sieve shaker uses YZU vertical vibration motor as the vibration source of the whole machine. The vibration motor drives the upper vibrating plate to vibrate, and then conducts the vibration through the vibration plate to the upper screen frame of the vibration plate, and then the screen frame needs to detect the mesh. The material particles smaller than the screen aperture are screened to the lower screen frame, so that only the same particle size material is left in each layer of the sieve, so as to achieve the separation of different particle sizes and determine the particle size composition of the material.

| No. | Name | Unit | Parameters | |

| 1 | Standard sieve body | Layers | 1~8 | |

| 2 | Screen diameter | mm | Φ200 Φ100 Φ75 | |

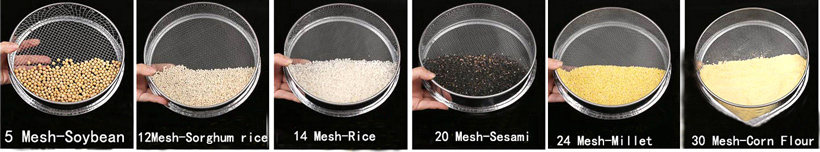

| 3 | Sieve particle size | mm | 0.038~5 | |

| 4 | Noise | dB | ≤50 | |

| 5 | Feeding amount (one-time) | Kg | ≤1 | |

| 6 | Amplitude | mm | ≤5 | |

| 7 | Motor | Voltage | V | 220 |

| Rotating speed | r/min | 1420 | ||

| Power | kw | 0.125 | ||

| 8 | Total Weight | Kg | 36 | |

| 9 | Timing | min | 0~99 | |

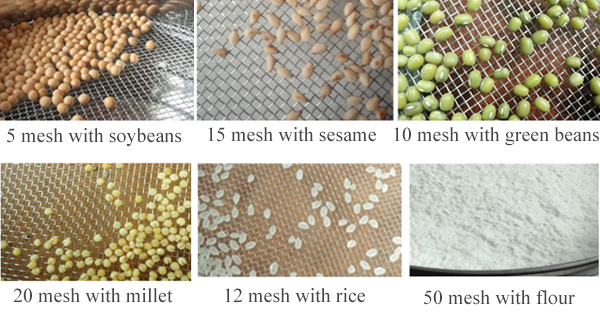

Mesh, which is the number of holes, is the number of holes per square inch. The larger the mesh number, the smaller the aperture. Generally speaking, mesh × aperture (number of microns) = 15000. For example, the aperture of a 400-mesh screen is about 38 microns; the aperture of a 500-mesh screen is about 30 microns.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

Material:SS wire 201, 304, 304L, 316, 316L, 431, 321 etc.brass, alumium, pvc coated,etc.

Wire Diameter:0.025mm -- 2.0mm,Special could be customized

Mesh count: 5-60

Weave pattern:Plain,twill,dutch Weave.

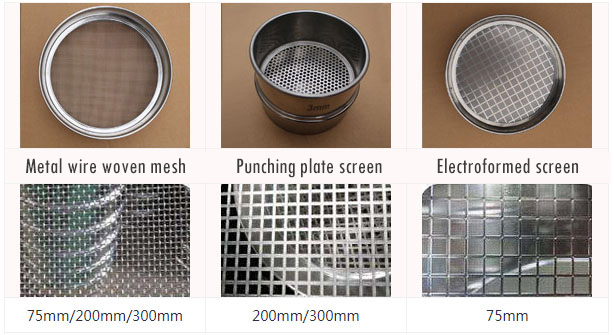

Industrial sieve shakers are available in three screen materials, each with different characteristics and application areas:

Metal wire woven mesh (2.36mm-0.02mm): good toughness, suitable for screening larger particle products.

Punching plate screen (≥3mm): the mesh precision is uniform and not easy to deform, suitable for screening large particle products.

Electroformed screen (500mm-5μm): the smallest screen hole, suitable for very fine product screening.

Industrial sieve shaker is a kind of equipment commonly used in laboratories for accurate sieving, filtration and detection of particle size structure, liquid solid content and foreign matter content of granular and powdery materials.

Chemical industry: resin, paint, medicine, medicine, cosmetics, fire extinguishing agent, plastic powder, abrasive glass, etc.

Ceramic industry: abrasives, alumina, porcelain mud, clay mud, glass powder, refractory materials, quartz sand, PVC resin powder, citric acid, polyethylene powder, washing powder, etc.

Food industry: sugar, monosodium glutamate powder, salt, fruit juice, starch, milk powder, food, soy milk, egg powder, rice noodles, soy sauce, fish meal, pineapple juice, etc.

Metallurgical industry: carbon black, cosolvents, activated carbon, pearls, etc.

| MATERIAL | MESH OPENING(MESH) |

| Flour | 40~60 |

| Face mask powder | 100~120 |

| Cellulose powder | 80~100 |

| 3D printing powder | 300~500 |

| toner | 80~120 |

| Plastic particles | 10~120 |

| Glass powder | 500~1000 |

| Ceramic powder | 325~1250 |

| Micro silica fume | 400~600 |

| Spice Powder | 60~150 |

Woven wire, usually square mesh, the most common type of screen(2.36mm-0.02mm)

Perforated plate screen (mainly used in large meshes, with round and square meshes ranging from 0.2 to several hundred millimeters)

It is made by mechanical punching of metal plate, the mesh is usually square or round, with good flatness and high compressive strength, suitable for soil and rock sample testing

Electroforming screen (mainly used in high-precision occasions, each mesh can be within the average error range, can be as fine as 5μm).

The finest sieve type, the mesh is extremely fine, only suitable for the analysis of a small amount of light and thin samples, and it is forbidden to handle heavy

Stainless steel Industrial Sieve Shaker: The most common type of stainless steel material, the sieve frame is polished, smooth and rust-free, and the sieve is flat, suitable for sieving of most samples.

Brass Analytical Industrial Sieve Shaker: Compared with Analytical Test Sieves made of stainless steel, brass has weaker properties and is a very traditional test sieve, but it is still used in some special occasions or in some regions.

Nylon Analytical Industrial Sieve Shaker: all made of PVC material, anti-corrosion nylon mesh, no metal, no magnetism, no static electricity. Handle sample materials that cannot be in contact with metals, such as: zirconium oxide, fluorescent powder, and some special chemical additives, etc.