Square Tumbler Screen is suitable for controlled screening, grading and dedusting of dry, powdered, granular products, especially suitable for high output and multi-layer separation of fine, light products that are difficult to screen.

Square Tumbler Screen adopts reciprocating gyratory screening, which transmits the vibrating and swaying motion of the vibrator to the screen surface, so that the material is rapidly dispersed in the front of the screen machine. The screen is continuously cleaned under the working state to ensure that the screen is not blocked. It is suitable for dry and wet screening of particles such as machine-made sand and quartz sand.

1. Large output of 1-50t/h

Reciprocating gyratory screening, quickly disperse materials, the output is 5-10 times that of ordinary vibrating screen

2. Automatically clean the sieve

With its own bouncing ball to hit the screen, remove the particles or powder stuck on the screen, and keep the screen surface clean at all times

3. Multi-layer screening

1-5 layers of multi-layer design, two layers of screen boxes can be designed, which is equal to up to 10 kinds of screen mesh specifications, and various specifications of finished products can be obtained at one time

4. Dustproof and safe

The airtight structure and the gentle swinging form of screening do not cause pollution and waste, and are suitable for fragile, flammable, explosive and electrostatic materials.

The vibration force generated by the Square Tumbler Screen drive device is an inertial force whose direction changes regularly around a fixed axis. Its essence is the reciprocating inertial force formed by the rotation of the eccentric wheel around the fixed axis. The screening effect of the Square Tumbler Screen is achieved due to its inertia driving the movement of the material.

| model | Effective screening area (m²) |

power (KW) |

Screen inclination (º) |

Number of layers | Rotation frequency (r/min) |

Screen box stroke (mm) |

| FYBS1030 | 3 | 3 | 5-8 | 1-5 | 180-260 | 25-60 |

| FYBS1036 | 3.6 | 3 | ||||

| FYBS1230 | 3.6 | 4 | ||||

| FYBS1236 | 4.32 | 4 | ||||

| FYBS1530 | 4.5 | 5.5 | ||||

| FYBS1536 | 5.4 | 5.5 | ||||

| FYBS1830 | 5.4 | 7.5 | ||||

| FYBS1836 | 6.48 | 7.5 | ||||

| FYBS2030 | 6 | 7.5 |

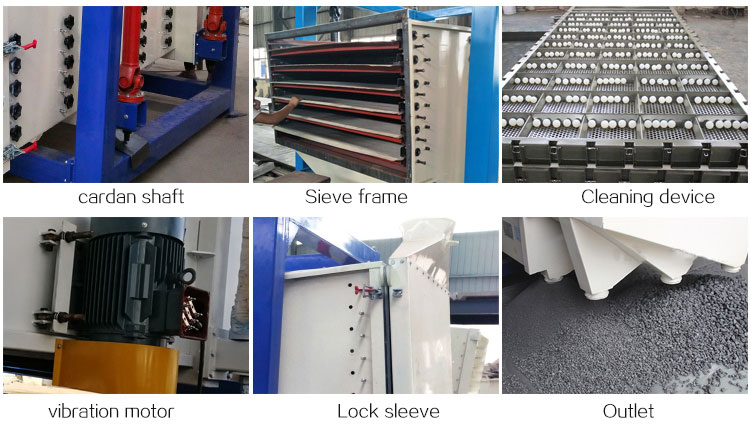

The Square Tumbler Screen itself has a certain inclination (about 0°-8°), which is mainly composed of the feeding port, observation hole, screen frame, screen, screen box, self-cleaning system, transmission, base, discharge port, motor and other parts composition.

1. Frame structure - key support: support the screen box;

2. Transmission - operating core: soften the exciting force generated by the motor;

3. Motor - power source: After the motor is energized, it provides running power for the entire machine;

4. Screen box and screen - screening main body: the screen box and screen are connected together by hook plates and screen clamps, the screen is stretched and the materials are more evenly dispersed, the screening accuracy is improved, and it is convenient to carry out the screening of the screen. Replacement, multiple screen boxes and multi-layer screens can be designed;

5. Self-cleaning system - auxiliary operation: the bouncing ball works while running, hitting the screen to solve the problem of material blocking holes;

6. Feeding port, observation hole and discharge port - close cooperation: observe the screening situation, automatically feed and discharge, suitable for assembly line work.

| General requirements | Model | YYBS1030/1036/1230/1236/1530/1536/1830/1836/2030 |

| Rotation frequency(r/min) | 180-260 | |

| main ingredient | Stainless steel (304/316L) \ carbon steel (Q235) | |

| Screen box stroke(mm) | 25-60 | |

| Sensor installation method | Built-in/External | |

| special requirements | sealing strip | Silicone/Rubber |

| Overall height | Please communicate in detail | |

| Inlet | Angle/Size etc. | |

| exit | Angle/Size/Valve | |

| Observation port | Silicone cover/Rubber cover/Glass cover | |

| spring | Can choose whether to add silicone protective cover | |

| Inner spray (mm) | PTFE/ePTFE/WC/Al2O3 | |

| Equipment surface treatment | Polishing/Sandblasting/Painting | |

| Body Metal Material Requirements | Example: Cu and Zn are not required (except electrical parts) | |

| vibration motor | Ordinary motor/explosion-proof motor | |

| other | Please contact us |

Square tumbler screen is widely used in chemical, metallurgical, abrasive, mining, quarrying, clay, glass, building materials, medicine, food processing, grain, plastics and other industries of fine classification. It can be used for the most demanding screening requirements of activated carbon, silica sand, fertilizer, limestone, petroleum coke, plastic particles, polyvinyl chloride powder, salt, sugar etc.

| materials | Mesh | Yield (KG/h) | Model |

| rubber powder | 24mesh | 1000 | FYBS-2000-2S |

| pepper seeds | 4mm | 500 | FYBS-600-3S |

| Petroleum coke powder | 110-120mesh | 3000 | FYBS-1500-2S |

| Panax notoginseng powder | 100mesh | 300 | FYBS-600-4S |

| Quartz sand | 2-200mesh | 6500 | FYBS-1536 |

| wheat | 6mm | 460 | FYBS-2000-2S |

| Chinese medicine powder | 325mesh | 600 | FYBS-600-4S |

| feed | 40mesh | 2200 | FYBS-1500-2S |

| fertilizer | 2mm | 10000 | FYBS-2600-1S |

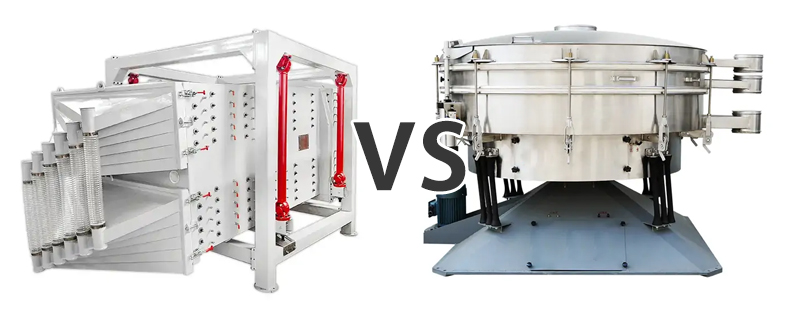

1、Material Adaptability

Square Gyratory Screen: It is widely applicable in industries such as chemicals, metallurgy, mining, feed, and food. It is particularly adept at handling various materials such as sand powder, carbon, heavy alkali, salt, resin, compound fertilizer, large and small particles of urea, and feed.

Circular Tumbler Screen:It is also suitable for multiple industries like chemicals, pharmaceuticals, food and spices, tea, feed, plastics, and rubber, particularly excelling in the grading of fine materials.

2、Screening Precision Consideration

Square Gyratory Screen: For materials below 300 mesh, SanYuantang’s square gyratory screen can provide excellent screening results. Its unique screening mechanism allows materials to vertically enter the screen surface and settle smoothly, enhancing screening efficiency.

Circular Tumbler Screen: With its design mimicking manual screening actions, Sanyuantang’s circular tumbler screen can effectively handle materials below 600 mesh, meeting the needs for higher precision screening.

Dahan machinery engineers are experts at suggesting the best equipment for existing operations and evaluating the solution most likely to improve the efficiency or capacity of your system. Based on our many years' experience on market development and project management, we provide specialized reconstruction services of production line for customers. Replacing old equipment with high-quality equipment greatly increases the output of production lines so that the customers can obtain huge return from relatively limited investment.