| picture display |  |

|

|

|

| Sieving Machine | Ultrasonic Sieving Machine | Powder Sieving Machine | Laboratory Sieving Machine | |

| $800.00-$4,500.00/Set | $800.00-$3,000.00/Set | $760.00-$3,090.00/Set | $860.00-$3,680.00/set | |

| Capacity | 100-3300kg/h | 100-5000kg/h | 3-30 t/h | ≤200g |

| Frequency | 1500 | 1500 | 1460(960) | 1420 |

| Mesh Size | 2-500 mesh | 10-635 mesh | 140 mesh | 20µm-125mm |

| Power | 0.25-3KW | 0.18-2.2 KW | 0.18-0.75 KW | 0.12KW |

| Usage/Application | High-capacity screening of powders, granules, and liquids | For ultrafine powder screening, prevent mesh blinding and blocking with ultrasonic system | It can be used directly in series in the pipeline to remove foreign matter and impurities in the pipeline | It can be used for particle size determination, separation and classification of powders, bulk goods and suspensions in the laboratory, |

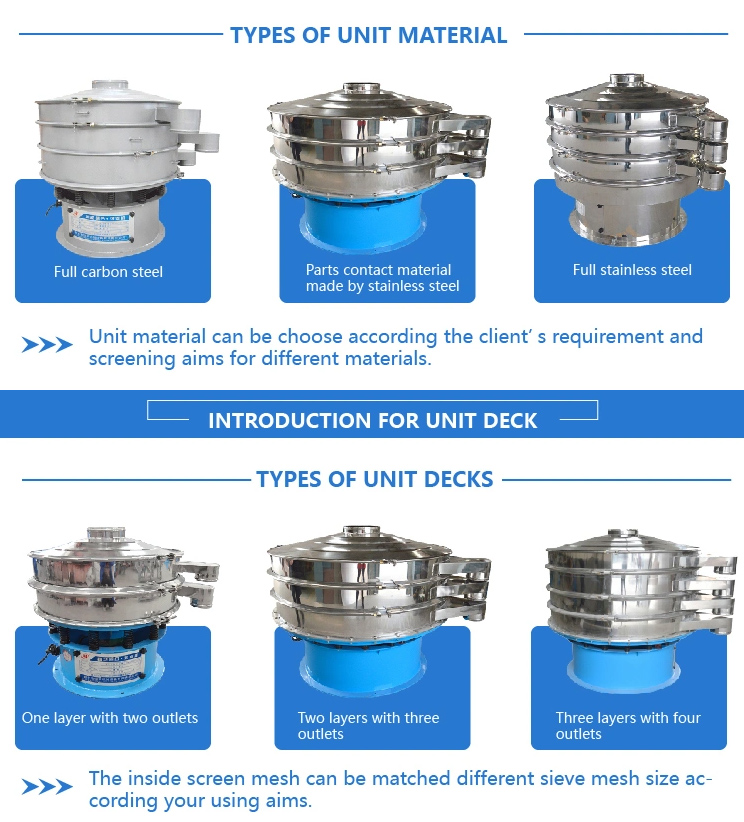

Carbon Steel Sieving Machine

The most common Sieving Machine is suitable for screening and impurity removal of common materials without special requirements and without corrosiveness.

Stainless Steel Sieving Machine

Usually made of 304 or 316L stainless steel, it is suitable for corrosive or hygienic materials, usually used in the fields of medicine, food and chemical industry.

PVC Plastic Sieving Machine

It also has the characteristics of corrosion resistance, suitable for processing some materials that are corrosive and cannot easily react with metals, and has relatively low price and weight.

In addition to the standard model of sieving machine, sieving machine can also be specially customized (non-standard) according to different material screening requirements:

Carbon Steel Sieving Machine

The feed port adopts a heightened protection design, and the edge design can increase the feed volume, prevent material splashing, and observe the screen condition.

Stainless Steel Sieving Machine

Install a scraper: The main purpose of installing a scraper is to dissolve, loosen and filter the material, so as to speed up the screening speed of the material through the screen and increase the screening output of the rotary vibrating screen.

PVC Plastic Sieving Machine

Gate type: The gap gate design can control the residence time and screening time of the material on the screen, ensure the processing accuracy of difficult-to-screen materials (viscous and fine materials), and increase the processing capacity.

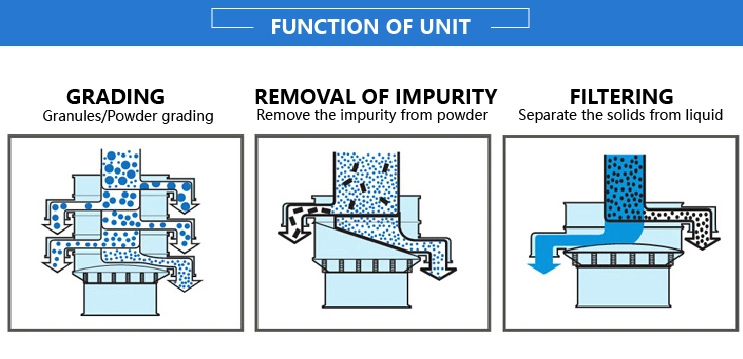

The Sieving Machine is driven by a vertical vibrating motor. When the vertical vibrating motor uses the centrifugal force generated by the high-speed rotation of the shaft and the eccentric block to obtain the exciting force, the exciting force is transmitted to the screen surface, and the materials on the screen surface are thrown From the beginning, it spreads out in a vortex shape in a jumping manner, and constantly contacts with the screen surface, so as to achieve the purpose of screening and grading materials.

Improve your product quality - Eliminate over-contamination in powders, ideal for screening incoming ingredients and final production inspection of finished products.

High throughput - suitable for sieving from 36 microns to 25 mm, allowing production of 100 to 25,000 kg/h, depending on product, mesh and machine feed flow.

High throughput - suitable for sieving from 36 microns to 25 mm, allowing production of 100 to 25,00 kg/h, depending on product, mesh and machine feed flow..

Multistage Separation - Holds up to 5 layers of sieves to separate up to 6 products of different particle sizes.

Reduced cleaning downtime - the unit can be easily disassembled without tools. All contact parts are fully washable

Safeguards operator health and safety - the patented clamping system securely seals the screen and prevents product leakage. This protects the operator from harmful dust.

Technical parameters are provided below! Customization services are also ready for you to contact.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

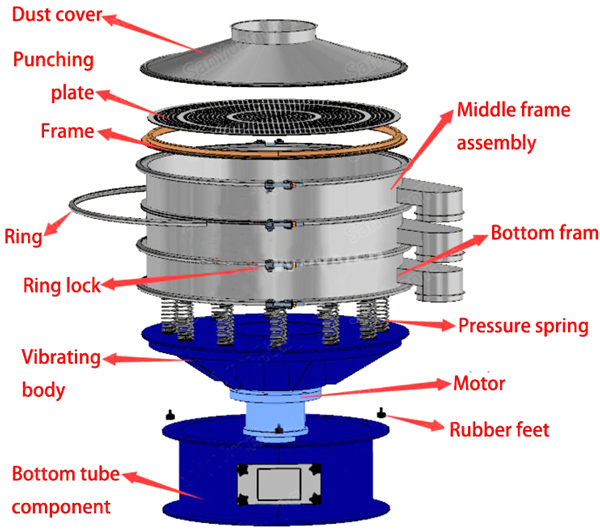

Sieveing machine consists of screen cover, screen frame, motor (vibration source), vibration isolation spring, base and other parts.

Dust cover: It is composed of feed inlet and inclined cone, and its lower end is connected with the screen frame to prevent the workshop dust from falling into the material when the vibrating screen is working. Commonly used materials are stainless steel, carbon steel and plastic. 3 other materials.

Screen frame: It is made of welded steel plate, with bearing rings at the upper and lower ends, and flange rings in the lower part, which are used to fix the structure of the screen members.

Vibration motor: vertical vibration motor, divided into four specifications: 2, 4, 6, 8, and horizontal. The number of vibrations is 2870, 1460, 980, 740RPM, and can be designed as explosion-proof type (flammable and explosive occasions)

Screen: Models are φ600, 800, 1000, 1200, 1500, 1800, etc. The materials are stainless steel, carbon steel, and plastic.

Cleaning device: to clean the blocked materials in the mesh of the screen to increase the output. It is available in silicone and rubber, with an optional ultrasonic cleaning unit (635 mesh electrostatic fine powder).

Shock-absorbing springs: There are 12-20 vibration-isolating springs along the vibration transmission body. The base is welded from steel coils. There are access doors and electrical switch sockets on the bottom wall. An annular flange is welded on the upper part of the base wall, and the flange is connected with the vibration transmission body through a vibration isolation spring.

| Model | Normal type | Edge type | Gate type | Filter type | High frequency |

| Image |  |

|

|

|

|

| Application | It can filter solid and liquid or carry out size classification and impurity removal of dry material | The screen frame is heightened and the feeding port is enlarged to prevent material splashing and easy to observe the screen. | The gate type design can prolong the screening time and improve the screening accuracy, suitable for fine powders, etc. | The screen frame is heightened and the feeding port is enlarged to prevent material splashing and easy to observe the screen. | Use a high-frequency vibration motor (3000 rpm) as the excitation source, suitable for filtering high-concentration slurries, such as ceramic glazes, etc. |

As a high-precision fine powder screening machine, sieving machine plays an important role in industrial production. Through the sieving machine, the material is divided into five grades: coarse powder, medium powder, fine powder, micro powder, and ultrafine powder. Sieving machine can be customized according to the different needs of customers with 1-5 layers of screens for simultaneous use.

The output of the sieving machine is from 100 to 5000 kg/h, depending on the product, the mesh size and the feed flow of the machine. It is suitable for screening materials from 36 microns to 25 mm. It allows the use of 5 layers of sieves and can separate up to 6 products of different specifications and sizes. It is widely used in food, medicine, chemicals, metallurgy, abrasives, ceramics and coatings.

Sieving Machine Widely used in the inspection and analysis of food, medicine, chemical industry, abrasives, pigments, mining,metallurgy, geology, ceramics, national defense and other industries in scientific research units,laboratories, inspection rooms, production control, etc.

1. Food screening or beverage filtering

Sieving Machine needs to be made of 304 or 316L stainless steel when processing food materials, in order to ensure the food safety of the materials. When filtering beverages, Sieving Machine uses a silicone sealing ring to seal between each sieve layer to avoid liquid leakage during filtration. At the same time, please choose a waterproof motor to ensure the safety of work and operation.

2. Chemical material handling

When the Sieving Machine is used for chemical processing, due to the particularity of the industry and the certain danger of some chemical materials, the Sieving Machine needs to use some special materials, such as stainless steel with high temperature resistance, PVC plastic that is resistant to strong acid and alkali corrosion and has no magnetism material, and special coatings can also be sprayed on the surface of the machine as required. Under normal circumstances, the Sieving Machine used in the chemical industry will choose an explosion-proof motor.

3. Experimental samples

When your processing requirement is to analyze the test samples in the laboratory, then choose the laboratory Sieving Machine, which has the advantages of large number of sieve frame layers, high sieve aperture standard, and conforms to ISO standards, and the laboratory Sieving Machine is small in size , easy to carry and can be placed on the laboratory operating table.