Electromagnetic Sieve is also a mechanical laboratory sieve, which drives stacked sieves and samples by shaking to achieve analysis and detection.

The Electromagnetic Sieve is an update or upgrade to the standard test sieve.

Electromagnetic Sieve uses an electromagnetic vibrator as the vibration source, with a vibration frequency of 3000 times/min. The sieve surface can generate high-frequency vibrations to promote the movement of sample particles, which can greatly improve the sieving efficiency of fine samples. Dry sieving can sieve to 20um (635 mesh), add negative pressure device, can dry sieve to 5um. Electromagnetic Sieve can hold 8 layers of test sieves (including the bottom of the sieve), and can precisely divide a sample into 2-9 particle size segments at the same time.

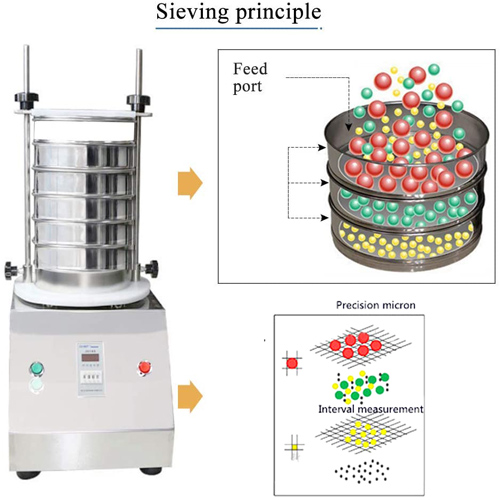

1. Three-dimensional vibration action: vertical, horizontal and rotating, which can produce faster and more effective screening. Because the screen surface can vibrate up and down at high frequency, the material can be thrown out of the mesh, and the material rarely sticks to the mesh.

2. The digital microprocessor control panel is adjustable: the timer is 0-99 minutes, continuous or intermittent vibration action, and automatic shutdown can be timed (for fine material screening).

3. Up to 8 sieves: The electromagnetic sieve shaker can be placed with 8 layers of test sieves (including the sieve bottom), which can precisely separate a granular material into 2-7 particle size segments at the same time.

4. Platform operation: The control panel can be fixed on the wall or placed on the workbench.

Electromagnetic sieve is a new type of test sieve, electromagnetic sieve shaker is a laboratory test sieve designed for ultrafine powder sieving detection on the basis of the original ordinary test sieve. The electromagnetic sieve has higher sieving accuracy than ordinary test sieves, which solves the problem that ultrafine powder is difficult to sieve.

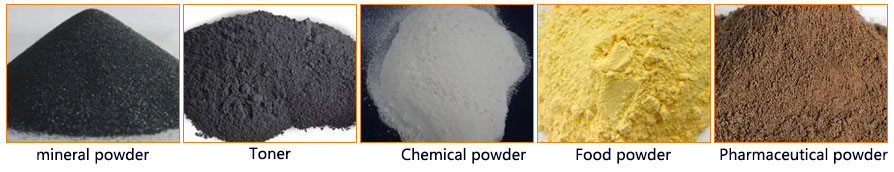

Fine particles, metal powder, carbon powder, chemical powder, food powder, pharmaceutical powder, diamond powder,building materials, dyes, ceramics, rubber, paper, dry and wet powders, etc.

| Materials | Mesh | Materials | Mesh | Materials | Mesh |

| Worm dung | 30 mesh | Soybeans | 4-5 mesh | green beans | 10 mesh |

| Rice | 12-14 mesh | rice flour | 30-40 mesh | Cornmeal | 30-40 mesh |

| flour | 50-60 mesh | Miscellaneous grains | 40-50 mesh | Sesame Millet | 22-24 mesh |

| Fried Chicken Burger Breaded | 20-30 mesh | Mung bean flour | 40-50 mesh | Sesame powder | 40-50 mesh |

| Notoginseng powder | 100-120 mesh | Pine pollen | 100-120 mesh | Chinese medicine powder | 40-50 mesh |

| Oral Chinese medicine powder | 60-80 mesh | Traditional Chinese Medicine Mask | 80-120 mesh | Pearl powder | 120-150 mesh |

| Medicine residue | 60-150 mesh | Soy milk | 80-120 mesh | honey | 80-120 mesh |

| Soup dregs | 120-150 mesh | Tea water | Cooking oilh | 120-150 mesh | 150-200 mesh |

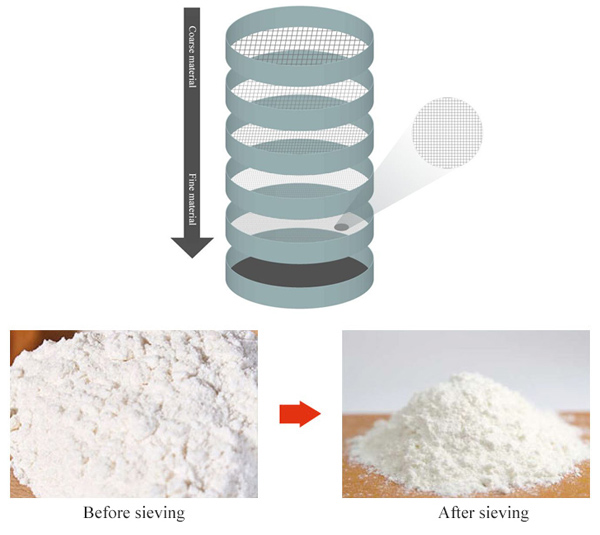

Electromagnetic sieve shaker uses electromagnetic vibrator as the vibration source. The vibration of the electromagnetic vibrator drives the base of the sieve machine to vibrate, and then transmits it to a set of standard test sieves arranged on the base from coarse to fine through the base seat, and vibrates up and down with high frequency. At the same time, the vibrating motor (or reciprocating mechanism) installed in the lower part spreads the material and produces a 3D throwing motion, so that the material particles smaller than the screen mesh of the test sieve are sieved into the lower test sieve, so that only the same size remains in each test sieve. The particle size of the material can be separated to achieve the separation of different particle sizes and determine the particle size composition of the material.

Electromagnetic sieve shakers are available in a variety of models:

A059-01 Kit: Dimensions Sieve Ø 200mm-8"; 320x380x850mm; Weight approx 40kg.

A059-02 KIT: Dimensions sieve Ø200-250-300-315mm-8"-12"; 380x440x1080 mm; weight about 65 kg.

A059-03 KIT: Dimensions sieve Ø 200-250-300-315-350-400 mm - 8"-12"; 430x460x1150 mm; weight approx. 80 kg.

A059-04 Kit: Size Sieve Ø 200-250-300-315-400-450 mm - 8"-12"-18"; 480x500x1150 mm; Weight approx. 85 Kg.

| Serial number | name | Unit | Value | |

| 1 | Sieve surface diameter | mm | Φ200/100/75 | |

| 2 | Number of layers of screen surface | Layer | 1——8 | |

| 3 | Number of swings | Times/Minutes | 290 | |

| 4 | Round trip distance | mm | 25 | |

| 5 | Number of round trips | Times/Minutes | 290 | |

| 6 | Number of vibrations | Times/Minutes | 3000 | |

| 7 | Amplitude | mm | 0——3 | |

| 8 | Motor | Power | KW | 0.37 |

| Speed | Revolutions/Minutes | 1400 | ||

| 9 | Dimensions | mm | 660X470X800 | |

| 10 | Weight of the whole machine | KG | 105 | |

1. If you need to adjust the vibration amplitude, you can adjust the potentiometer knob to get different amplitudes. If you adjust the material spreading range, please adjust the motor eccentric block. The method is to adjust the length of M8 bolts or additional screws on the excitation block on the motor to obtain different excitation forces. Generally not adjusted.

2. Adjust the time according to the screening needs. The first two digits of the time relay on the left side of the front panel of the electromagnetic sieve are minutes and the last two digits are seconds. The timing can be adjusted within 0-99 minutes and 59 seconds as needed.

3. For the test sieve used in the electromagnetic sieve shaker, the bottom layer is lowered (non-porous sieve), and the sieve cover is placed on the top. The middle of the sieve bottom and sieve cover can be put into 1-7 layers of test sieves according to the requirements of the sieving granularity section, from top to bottom, from coarse to fine, and the materials that need to be screened are put on the top (also the coarsest screen) layer.

4. Put the test sieve into the equipment and lock the nuts on the top and both sides. The specific method is: first loosen the four locking nuts on the top and both sides of the standard vibrating screen, so that the two columns on both sides can fall freely on the test screen that has been placed, and then lock the two sides of the screen first. Tighten the nut, just lock the two nuts on the top of the screen machine. Note: The nuts on the top and both sides must be tightened. The tightening is loosened when the two nuts on the top of the screen machine are on both sides of the top, and then the top nuts are tightened after pressing on both sides.

5. After completing the above steps, turn on the green button on the right side of the front panel of the electromagnetic sieve. After a period of time for screening, when the time ends, the screen machine will automatically stop, or you can press the red button to end the screening. At the end of the screening, you can screen out the materials with multiple particle size segments you need at one time.