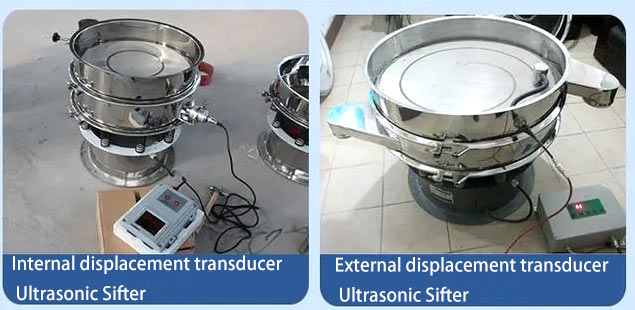

Internal displacement transducer Ultrasonic Sifter: screening of non-corrosive common powder materials, difficult to clean, high damage rate and low price;

External displacement transducer Ultrasonic Sifter: suitable for all powder material screening situations, not easy to damage, easy to clean, high price.

1. Ultrafine powder sieving - suitable for 10 micron to 200 micron screen to separate powder, especially for materials that are difficult to sieve;

2. No blockage - prevent the blockage of the mesh and the impact of similar particles on the mesh, and prolong the service life of the precious screen.

3.Improves product quality – Screen powders on meshes as fine as 20 microns without blinding or blocking, the precision can be improved by 1-70%.

4.Increases throughput capacity- speed up the separation of agglomerates, decompose adhering substances, and reduce the amount of oversized particles, thereby increasing the amount of sieves and reducing the number of large particles, and the output can be increased by 0.5-10 times.

5. Reduce production downtime - the ultrasonic system has its own screen cleaning function, and there is no need to add any other screen cleaning equipment, saving the time for cleaning the screen.

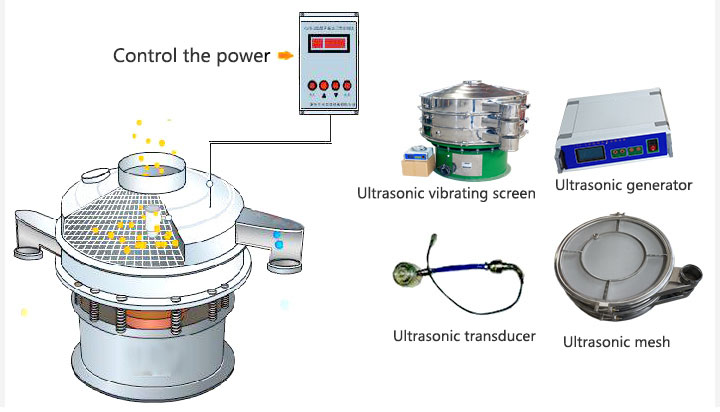

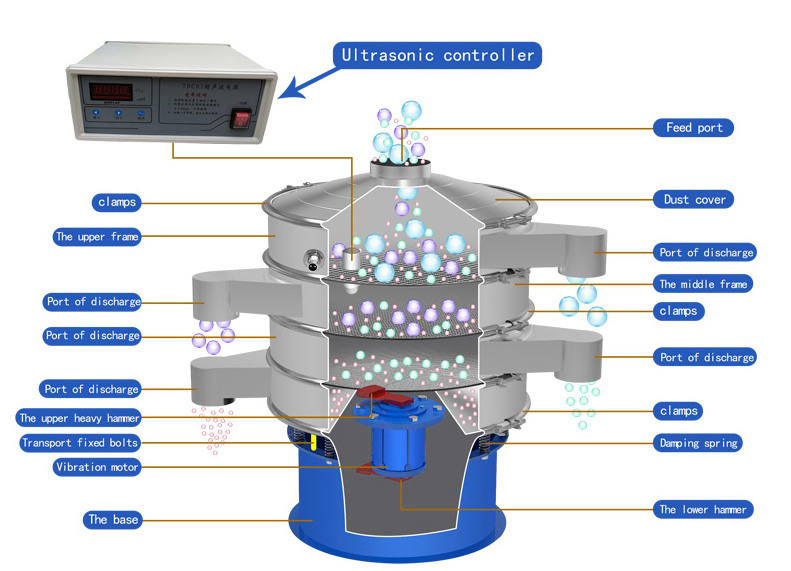

A ultrasonic sieving system comprises a generator, a converter and a matched screen resonator with installation frame. The generator and converter generate the vibrations and direct them into the resonator. Ultrasonic screening is a method that uses ultrasonic vibration technology to improve screening efficiency. It is particularly suitable for screening fine powders and high-viscosity materials.

Ultrasonic Sifter is to input 220V, 50Hz or 110V, 60Hz electrical energy into the ultrasonic transducer to make it into 36KHz mechanical vibration. The generated ultrasonic waves cause the screen to vibrate at high frequencies. Ultrasonic vibration is superimposed on the material on the sieve surface while undergoing low-frequency rotational vibration, which can not only prevent mesh clogging, but also improve the output and product quality of the sieving machine, making it easy for the Ultrasonic Sifter to sieve ultrafine powder.

| Model | Screen diameter | Screen specification | Power (kw) |

| DHC-400 | Φ350 | 80-600 meshes | 0.18 |

| DHC-600 | Φ550 | 0.25 | |

| DHC-800 | Φ750 | 0.55 | |

| DHC-1000 | Φ920 | 0.75 | |

| DHC-1200 | Φ1120 | 1.1 | |

| DHC-1500 | Φ1420 | 1.5 | |

| DHC-1800 | Φ1720 | 2.2 |

1) Ultrasonic vibro sifter uses an ultrasonic frequency to vibrate the mesh, and the vibration frequency can reach 36,000 times/second (ordinary vibro sifter vibration frequency is only 1450 times/second), so the ultrasonic vibro sifter solves the problem of the material generated when the material is sieved through the mesh. Excellent electrostatic adhesion, eliminating problems such as mesh clogging, suitable for light specific gravity, viscous or ultra-fine powder with static electricity.

2) The screening fineness and grade are greatly improved. For the materials with higher requirements, the screening is completed at one time, which significantly improves the product qualification rate and improves the production efficiency;

3) It does not change the characteristics of the screened products and has a wide range of applications.

4) Ultrasonic screening can increase sieving capacity tenfold by enabling powders to pass through meshes faster.

5) The pollution caused by the conventional screening method to the sieved powder is eliminated and the noise pollution is reduced to a large extent.

| Model (mm) |

Testing materials | Ordinary Vibro Sifter | UItrasonic Vibro Sifter | ||

| Mes | Test results | Mesh | Test results | ||

| 1000mm | Silicon carbide | 500 | Unable to screening | 500 | 1500KG/H |

| Tungsten powder of cemented carbide | 600 | No fine powder was sifted out for 15 minutes | 600 | 30KG/H | |

| vitamin c powder | 400 | 1KG/H | 400 | 120-150KG/H | |

| 600mm | Pollen | 400 | No fine powder was sifted out for 15 minutes | 400 | Screen out 20% in 15 minutes.Fine and effective classification can be carried out in fine workmanship. |

| Nickel powder,Cobalt powder | 325 | Screen three times to meet the requirements | 400 | Screen once to meet the requirements | |

| 400mm | Ndfeb powder | 300 | 32.2% residual sieve in 30 minutes | 300 | 6.9%residual sieve in 30 minutes |

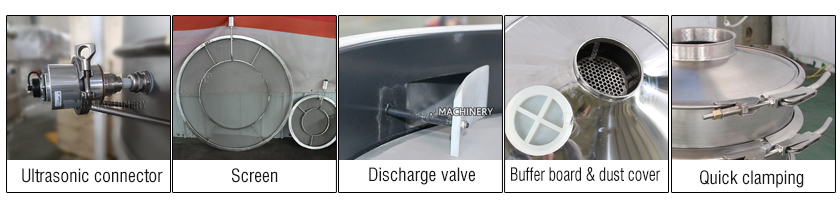

Ultrasonic vibro sifter consists of ultrasonic connector, screen, inlet, outlet and resonance ring.

Ultrasonic connector: It solves the problem of blocking the screen like adhesion.Improves the screening and cleaning efficiency.Solves the screening problems such as adsorbing strongly, easy to agglomerate, high static electricity, and so on.

Screen: The screen mesh can be up to 500 mesh.

Discharge valve: Adjust the discharging speed through valve as your required, so that increasing the screening accuracy.

Buffer board & dust cover: The buffer board makes the materials flow into the screen surface evenly.Dust cover prevents the dust flying.

Quick clamping: Quickly open the clamp ring to replace the screen.Reduce labor intensity.

Ultrasonic vibro sifter for graphite powder

Ultrasonic vibro sifter for plastic pellets

Ultrasonic vibro sifter for heavy calcium powder

1. Increase the height of the screen cover: increase the material holding capacity of the upper screen frame to prevent material splashing, and an observation window can be installed on the screen cover to facilitate observation of the screening situation in the screen;

2. Gate design: an active valve is added to the discharge port, which can close or adjust the flow of the discharge end, and can artificially control the duration of material screening and improve the fineness of material screening;

3. Integrated silo type: the feed port is connected to the feeding silo, and the silo has its own adjustable valve, which can control the feeding flow while cooperating with the feeding equipment.

4. Explosion-proof motor: BZDL explosion-proof vertical vibration motor is used to meet the screening requirements or usage scenarios of some flammable and explosive materials;

5. Gas protection device: It is mostly used in the field of 3D printing industry. It has a more airtight design and can be filled with inert gas to prevent pollution while strictly screening.

Ultrasonic Sifter is suitable for sieving powder or fiber materials that are light and fine, easy to stick to the net, easy to generate static electricity, and difficult to sieve. The sieving powder output is 1-10 times that of ordinary vibrating sieves.

Application materials: Chinese and Western APIs, Western medicine, coffee powder, cocoa powder, condiments, food additives, metal powders, copper, iron, aluminum, lead, zinc, alloy powders, magnetic materials, metal powders, alumina, corundum, emery, Quartz sand glass beads, abrasive materials, plastics, rubbers, resins, dyes, fillers, chemical chemicals, activated carbon, wood powder, wood chips, charcoal, fiber materials.

1、Ultrasonic Sifter in chemical plants

When Ultrasonic Sifter is applied to chemical powder processing, it has good sealing and screening accuracy, which can effectively screen the preparation while ensuring that the chemical preparation does not leak.

2、Ultrasonic Sifter application in pharmaceutical production

Ultrasonic Sifter is made of 316 medical stainless steel, which is safe, hygienic and non-toxic. It can be connected to vacuum feeders, packaging machines, etc., and can complete the processing of pharmaceuticals without manual intervention.

3、Ultrasonic Sifter for food powder processing

The Ultrasonic Sifter for food powder processing is 304 stainless steel for food. It can quickly process a large amount of flour, coffee powder and other materials. It can be connected with equipment such as grinders, packaging machines, and processing machines to complete the assembly line processing of food.