1. The inlet and outlet are designed in the same vertical direction. The large flow outlet at the bottom allows the material to be discharged directly, reducing the residence time of the material on the screen surface. The material is discharged quickly and the processing capacity is 2-5 times that of ordinary circular vibrating screens. Combination of production lines.

2. It can be used directly in series in the pipeline to remove foreign matter and impurities in the pipeline without manual operation and avoid secondary pollution of materials.

3. Good air tightness, no dust scattering, can be used directly with the dust-free feeding station to achieve negative pressure and dust-free operation.

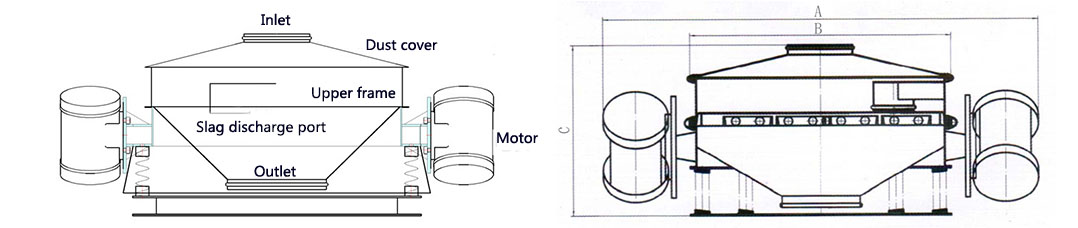

4. There are two arrangements of single motor and double motor, which can be adjusted from 30 to 60 degrees to increase the running track of the material.

5. The motor is designed on the outside of the equipment, reducing the height of the equipment and making effective use of the space; the equipment is easy to operate, and the large obtuse angle is easy to clean.

A horizontal vibration motor is installed on one side of the vibration body of the direct discharge sifter or a horizontal vibration motor is installed on both sides of the vibration body. The excitation force is generated by the unbalanced eccentric weights installed at the upper and lower ends of the horizontal motor shaft. The rotation of the screen surface makes the three-dimensional vibration of the screen surface in the horizontal, vertical and inclined directions, so that a large number of materials under the screen can quickly pass through the mesh holes and enter the next process vertically through the discharge port.

| model | power(kw) | Motor speed(r/min) | A | B | C |

| ZPS-600 | 0.18 | 1440 (960) |

1070 | 600 | 502 |

| ZPS-800 | 0.25 | 1390 | 800 | 525 | |

| ZPS-1000 | 0.37 | 1566 | 970 | 543 | |

| ZPS-1200 | 0.55 | 1875 | 1170 | 814 | |

| ZPS-1500 | 0.75 | 2226 | 1470 | 875 |

| 型号 | A | B | C | D | E | F | G |

| ZPS-600 | 600 | 150 | 380 | 560 | 325 | 120 | 80 |

| ZPS-800 | 800 | 200 | 540 | 600 | 350 | 125 | 90 |

| ZPS-1000 | 970 | 250 | 640 | 640 | 350 | 150 | 100 |

| ZPS-1200 | 1170 | 250 | 700 | 700 | 400 | 180 | 120 |

| ZPS-1500 | 1470 | 250 | 760 | 760 | 440 | 200 | 120 |

Direct discharge sifter is used for: paint, veterinary drugs, flour, fertilizer granules, pebbles, Oreo powder, lithium carbonate, lithium hydroxide, dyes, food additives, ammonium sulfide, lime powder , Sand, coal powder, plastic additives, condiments, sodium sulfate, metal powder, chemical raw materials, starch, silicon carbide, zinc oxide powder, puffed soybeans, feed additives, calcium powder, soda ash.

Sieving starch

In-line sieve for sieving washing powder

Direct discharge sifter with dust-free feeding station