Stainless Steel Linear Vibrating Screen is a linear screening system widely used in industrial fields, which can separate materials into various specifications according to size. The biggest feature of the Stainless Steel Linear Vibrating Screen is that it is made of 304 or 316L stainless steel, which can avoid contamination of food or medical materials, and at the same time ensure that the machine itself is corrosion-resistant and rust-free, and has a longer service life.

Stainless Steel Linear Vibrating Screen has 1-6 layers of screens, which can divide materials into 2-7 grades according to particle size (grade is calculated as: number of layers + 1), and each layer of screen box is fixed with buckles, which can be easily disassembled , to facilitate the replacement of the screen or the change of the number of layers of the screen box.

Features

1. Safety and hygiene. Stainless steel material for food or medicine, non-toxic and non-rusting.

2. Corrosion and wear resistance. Stainless steel has strong corrosion resistance and is not easy to wear.

3. The whole machine is finely polished and polished, smooth and flat, and the material will not be difficult to clean due to attachment to the screen wall.

4. Closed system. The whole machine is a closed structure, which can eliminate the dust problem in the air without causing pollution or material waste.

Due to the characteristics of the material, Stainless Steel Linear Vibrating Screen is usually used in industries with high hygiene standards such as food and medicine, or in some corrosive chemical industries.

Stainless Steel Linear Vibrating Screen is a kind of vibrating screen designed for sieving food, medicine and other materials with high hygienic standards, as well as acid-base corrosive materials in medicine and chemical industry.

The mesh size of the sieve is between 2-400 mesh, and the mesh number varies according to the product type. It can meet the requirements of primary filtration, impurity removal and fine screening of particles, powders, liquids and other materials.

| Product | Proportion | Mesh | Capacity(kg/h) | Model |

| Millet | 0.15 | 250 mesh | 600 | DZSF-515-2s |

| Quartz sand | 1.6 | 70 mesh | 30000 | DZSF-1540-3s |

| Raisin | 0.83 | 60 mesh | 6000 | DZSF-520-1s |

| Sunflower seeds | 0.04 | 80 mesh | 7100 | DZSF-525-1s |

| Plastic particles | 0.95 | 3 mm | 500 | DZSF-515-2s |

| Flour | 0.6 | 24 mesh | 1500 | DZSF-515-3S |

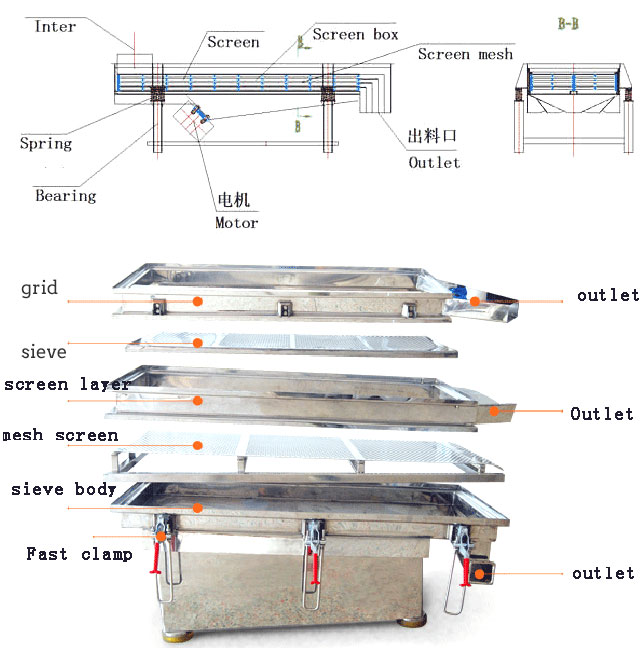

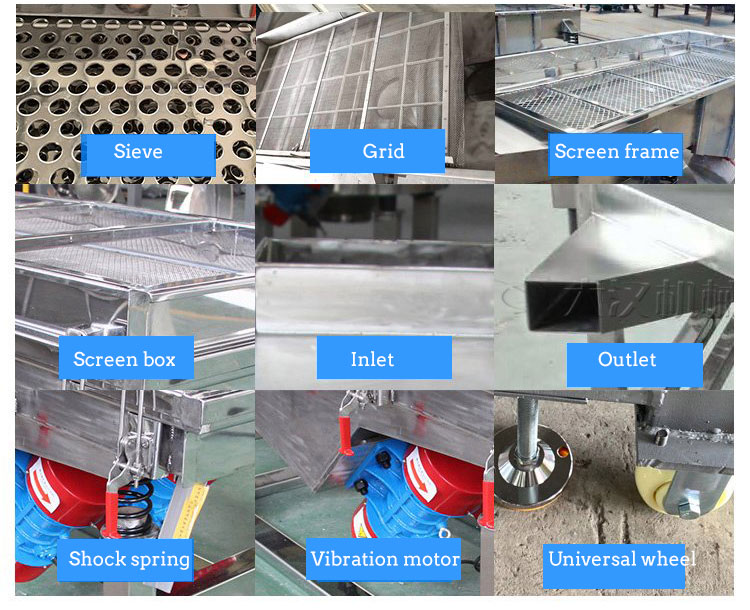

Linear Vibrating Screen is mainly composed of feed inlet, dust cover, screen box, screen mesh, discharge outlet, vibration motor, force guide plate, shock absorbing spring and base from top to bottom.

SScreen: mainly used for material screening, the aperture size of the screen ranges from 2 mesh to 400 mesh, and can be installed according to different screening requirements;

SScreen box: the main structure, providing a fixed space for the materials to be screened;

S Dust cover: reduce dust pollution and material waste;

SMaterial inlet and outlet: can automatically feed and discharge materials to achieve fully automatic production;

SVibration motor: power source;

Shock-absorbing spring: It plays a shock-absorbing role while transmitting the exciting force to avoid damage to the screen box.

The machine structure of the Stainless Steel Linear Vibrating Screen is more refined than the general linear vibrating screen. After grinding and polishing, the material will not adhere to the side wall of the screen box, ensuring more hygienic and easy to clean.

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |