Filter sieve also adds filter sieve machine, which is suitable for single-layer sieving and filtration of manufacturers in various industries, and handles materials with little production volume or less impurities, such as: powder sieving and slurry filtration with large particle content; 325 mesh filtration specific gravity 1.1 spray paint material, up to 1200 liters per hour; 30 mesh sieved flour can process 700 kilograms per hour.

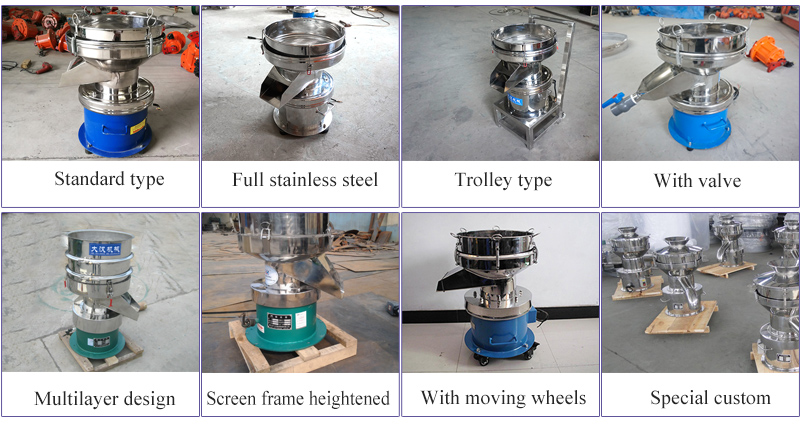

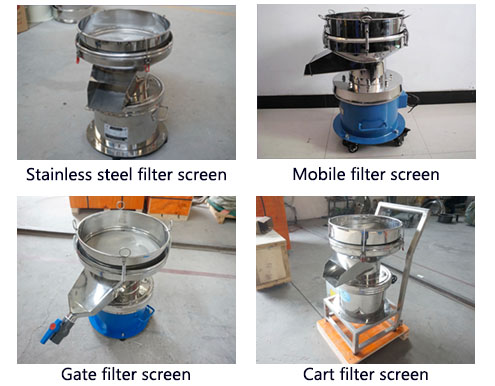

Filter sieve machine is suitable for single-layer sieving and filtration used by manufacturers in various industries. It can handle materials with small production volume requirements or less impurities. Generally, the equipment can be selected when the amount of sieve (impurities) does not exceed 5%.

Chemical industry: paint, ink, color paste, paint, latex paint, aluminum powder paste.

Food industry: starch, soy milk filter, fruit juice, beverage, dairy mouth, condiment.

Other industries: mud, pulp, waste liquid, Chinese and Western medicinal liquid, etc.

1. Stainless steel (304) material is more conducive to liquid filtration and impurity removal.

2. The motor with waterproof grade IP54 + anti-seepage water treatment, the operation is safer, and the damage to the motor caused by liquid can be prevented.

3. The heightened design of the screen grid prevents the slurry from splashing, and the large observation port makes it easy to observe the screen surface.

4. Independent 360-degree automatic spray head, 100% screen cleaning, automatic cleaning (prepared according to the characteristics of materials).

5. Special inlet and outlet gates, the cloth is more uniform and the precision is higher.

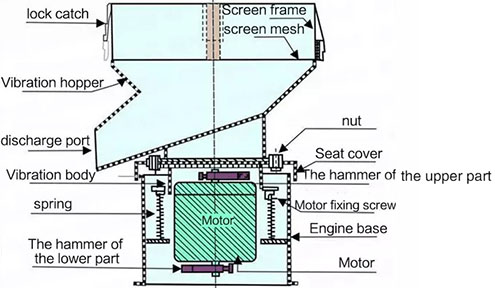

The filter screen has the vibration of the motor eccentric block, which makes the screen body produce horizontal,vertical and inclined three-dimensional motion (the difference of the eccentric block angle affects the running track of the material on the screen) so that the material is thrown up on the screen and from the center to the outside. It rotates and spreads to the discharge port for discharge, and the material is divided into two different grades of material on the screen and under the screen by using the different size of the screen mesh.

| Model | Screen area | Frequency | Power | Voltage | Layer | Screen range |

| DH-450 | Φ400mm | 1440 | 0.18 | 380V | 一 | 0.038-3mm |

Filtered soy milk

Sieving flour

Replacement steps of screen