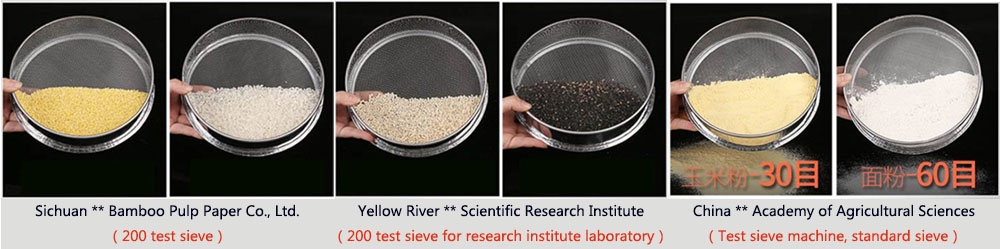

The sieve shaker is a sieving device that meets the technical requirements of the experimental sample sieving standard and is used for particle size analysis of samples. Through the nesting of multiple sieves with different apertures, samples of different sizes are retained in the corresponding sieve frames to achieve particle size separation of research samples.

In order to ensure the accuracy and repeatability of sample sieving, the sieve shaker is designed with a 0-99 minute timing device to achieve timing sieving accurate to the second.

There are a wide variety of sieve shakers. In order to measure different types of samples and achieve the best processing effect, different types of sieve shakers need to be selected.

Rotap sieve shaker

The Rotap sieve shaker rotates to the slide plate through the rotation of the motor, drives the test sieve to shake left and right, and at the same time drives the ejector pin gear to rotate, hits the hammer, and slaps the sieve placed on the Rotap sieve shaker to realize sample separation.

Standard sieve shaker

The standard sieve shaker drives the sieve to shake and circularly move through the motor, so that the samples in the sieve can be classified.

Electromagnetic Sieve Shaker

Electromagnetic Sieve Shaker drives the sieve to work through the joint action of electromagnet and spring. Electromagnetic typically produces ultrasonic vibrations with higher sieving frequencies and a unique 3D motion.

The criteria for selecting a sieve shaker should be determined by the characteristics of the sample.

The sieve shaker can handle samples in various states from rock to fine powder, but the processing effect depends on the correct equipment selection and correct operation in sample analysis.

If your sample has large particles, such as stone particles of about 20mm, choose Rotap sieve shaker or standard sieve shaker, or your sample cannot pass through the sieve well (if the actual sample particle size meets the specification) , select Rotap sieve shaker.

If the sample state is simple and the sample fineness is 0.8-0.1mm, choosing a standard sieve shaker can achieve good analysis results.

When the sample state is fine and fine powder, choosing Electromagnetic Sieve Shaker will achieve more accurate analysis results.

1. The sieve shaker is small in size and light in weight. It can be placed on the laboratory operating table and takes up less space.

2. It can realize the separation of 2-8 grades of samples, and the screening accuracy is high.

3. The 0-99 minute timing system can analyze samples accurately and repeatedly.

4. Compared with manual analysis, the accuracy is higher and the analysis time is shorter.

5. Simple operation and low purchase cost.

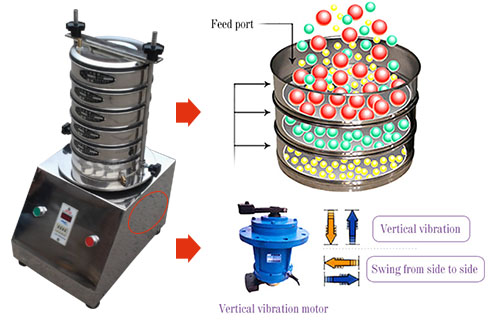

The sieve shaker uses a vibrating motor as the excitation source, and the vibration of the vibrating motor is transmitted to each layer of screen frame through the base, so that the material is screened into differentlevels from different screen holes.

| Serial number | name | unit | data | |

| 1 | Standard screen body | Floor | 8 | |

| 2 | Screen diameter | mm | φ200φ2100φ275 | |

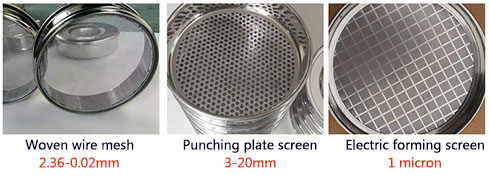

| 3 | Screening size | mm | 0.038-3 | |

| 4 | noise | dB | ≤50 | |

| 35 | Feeding amount (one-time) | g | ≤200 | |

| 6 | amplitude | mm | ≤5 | |

| 7 | Motor | Voltage | V | 220 |

| Rotating speed | r/min | 1420 | ||

| power | KW | 0.125 | ||

| 8 | Dimensions | mm | 360×300×736 | |

| 9 | Overall quality | Kg | 25 | |

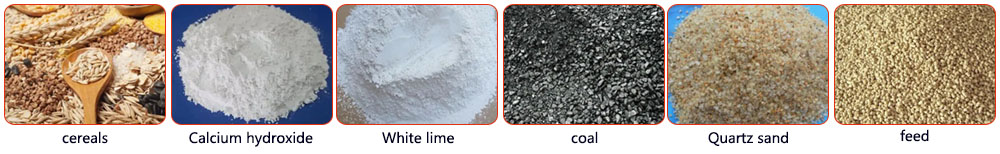

Sieve shaker is suitable for: grains, calcium hydroxide, white lime, coal, aluminum paste, gemstones for nail art,coal water slurry, white clay, glass powder, quartz sand, steel shot, fertilizer, feed, flour, coal slime,drysand , Tea, perlite, resin, plastic particles, iron powder, alloy powder, etc.

bismuth tungstate--500 mesh

sieve shaker for testing soil

how to use sieve shaker