Sand screening test Experimental purpose

Saturday May-17 2025 14:01:06

What is a sand screening test experimental purpose?

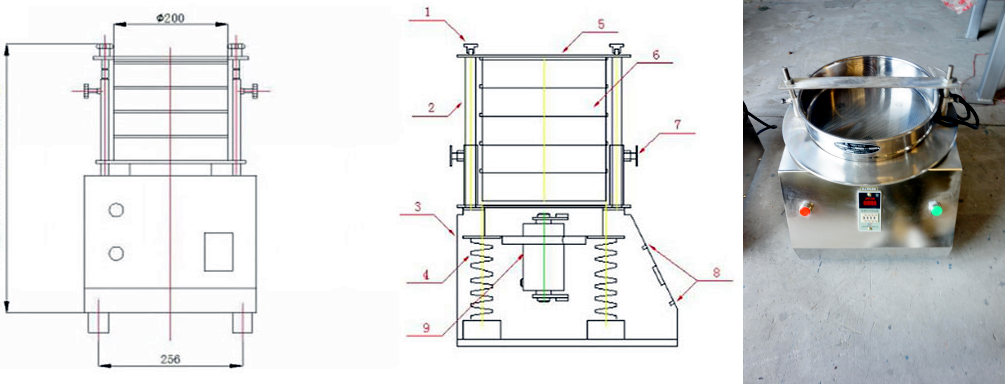

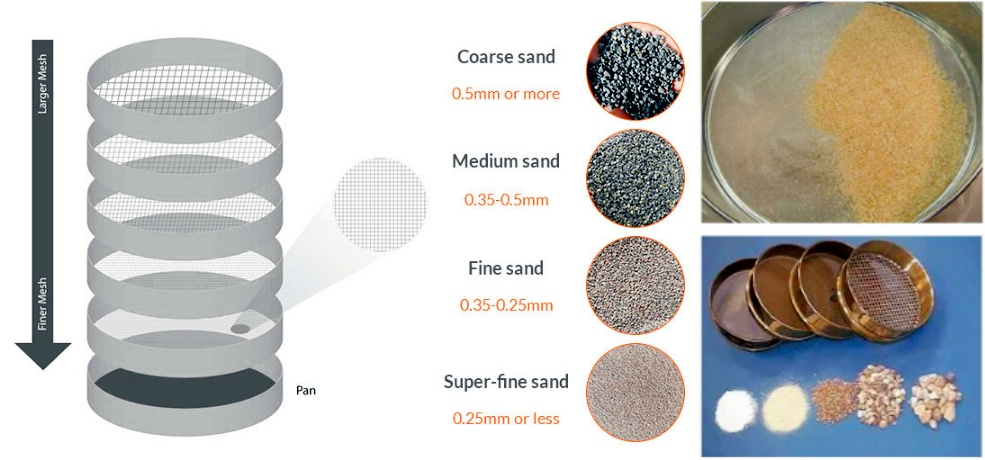

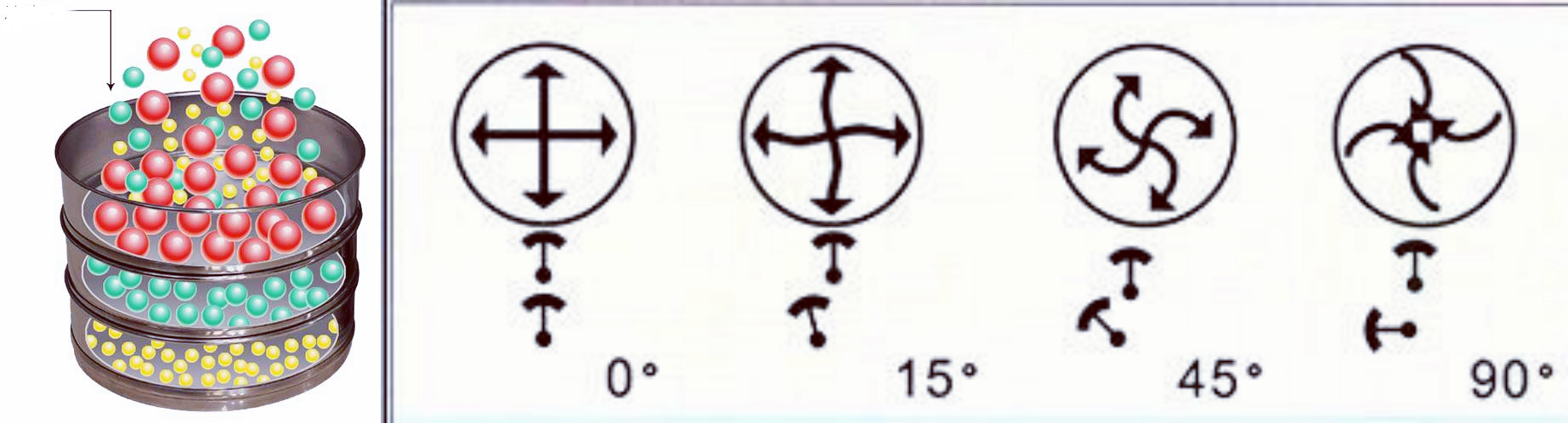

The sand screening test mainly uses a set of standard sieves, arranged in order according to the particle size, and uses mechanical or manual vibrating sieves to separate and weigh particles of different particle sizes, so as to obtain the mass percentage of each particle size, and finally calculate the fineness modulus and particle grading. The fineness modulus is an indicator reflecting the coarseness of sand. Its calculation method is to divide the cumulative percentage on each level of sieve by 100. The larger the value, the coarser the sand.

1. Determine whether the particle grading of sand is qualified

The definition of particle grading: refers to the matching ratio or distribution of sand particles of different particle sizes in the whole.

Test logic: The sand sample is screened through a set of standard sieves (such as square hole sieves, the aperture is usually 9.50mm, 4.75mm, 2.36mm, 1.18mm, 0.60mm, 0.30mm, 0.15mm, etc.), weigh the mass of the sample on each sieve, calculate its percentage of the total mass (that is, the percentage of the sieve residue), and further calculate the cumulative percentage of the sieve residue.

Standard comparison: Compare the calculated cumulative sieve residue percentage with the particle grading range specified in the standard (such as "Construction Sand" GB/T14684) to determine whether the particle grading of the sand meets the requirements (such as divided into three grading zones: Zone I, Zone II, and Zone III, corresponding to different engineering uses).

2. Provide a basis for concrete mix design

The impact of particle grading:

Void ratio: Well-graded sand has a reasonable particle size and a small void ratio, which can reduce the amount of cement slurry in concrete, reduce costs and increase strength.

Workability: Appropriate grading can improve the workability of concrete mixtures (such as fluidity, cohesion, and water retention), avoid segregation, bleeding and other problems.

Test function: Determine the coarseness (such as fineness modulus) and grading category of sand through screening results, provide key parameters for the selection of sand in concrete mix design, and ensure that the performance of concrete meets engineering requirements (such as strength, durability, etc.).

3. Evaluate the processing quality or source suitability of sand

Engineering application scenarios:

Natural sand: Determine whether the particle size distribution of natural sand such as river sand, sea sand, and mountain sand is uniform and whether it meets the requirements of different projects (such as masonry, plastering, concrete pouring, etc.).

Mechanical sand: Evaluate whether the particle size distribution of artificially crushed sand meets the production process standards, and whether there are problems such as particle size concentration and excessive stone powder content.

Quality control: Monitor the quality of sand production, processing, and transportation to prevent unqualified sand from entering the construction site and affecting the quality of the project.

4. Perform quality control and predict material properties

In the production and use of sand, screening tests are important quality control methods. Regular testing can ensure that the quality of the supplied sand is stable and meets the requirements of the project. The particle size distribution of sand is related to many physical and mechanical properties, such as porosity, permeability, shear strength, etc. The results of the screening test can predict the behavior of sand in actual projects to a certain extent.

Precautions

The sample needs to be fully mixed and representative to avoid segregation.

The screening time should be sufficient to ensure that the particles are fully separated and to avoid entrainment.

Weighing should be accurate, the instrument should be calibrated, and the screen should be intact.

The particles after screening can be checked repeatedly, and if the distribution is abnormal, they should be screened again.

The fineness modulus should not be used as a single criterion, but should be judged in combination with actual use and other test data.

The Sand screening test provides a scientific basis for engineering material selection, mix design and quality control by quantifying the particle gradation and coarseness, and is a key link in ensuring the performance of materials such as concrete and mortar in construction projects. The particle gradation of sand is analyzed by scientific methods to provide a basis for the selection and quality control of engineering materials. The experiment is divided into modules such as preparation, screening, data processing, and result analysis. Each module must be operated strictly in accordance with the specifications to ensure the accuracy and reliability of the data. The test results can be used to judge the applicability of sand, optimize engineering design, and provide data support for subsequent material proportioning.