Differences between ultrasonic test sieve and ordinary test sieve

Thursday May-15 2025 17:46:11

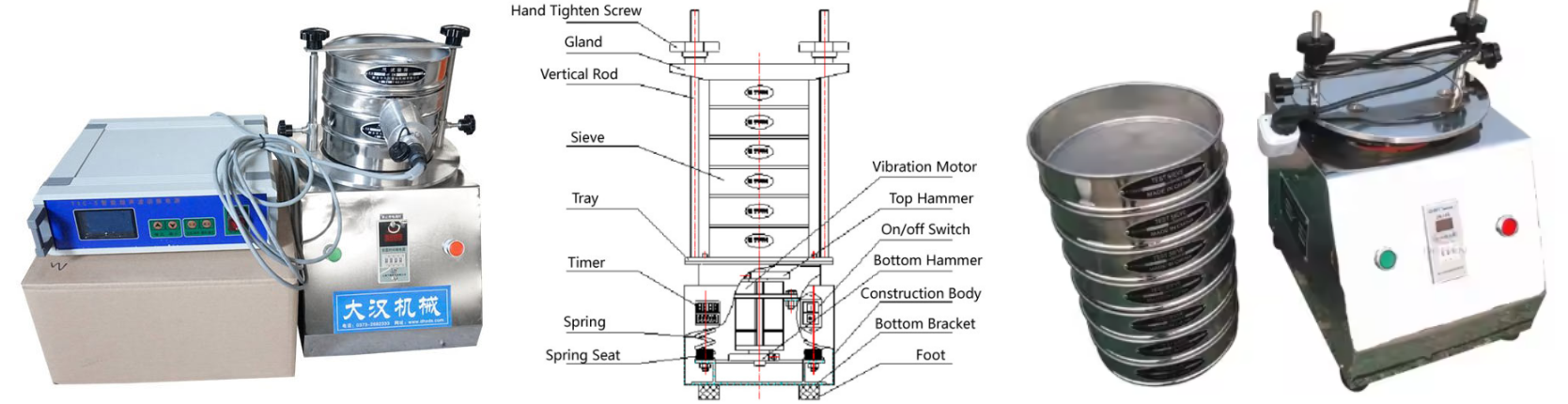

Although both ultrasonic test sieve and ordinary test sieve are equipment for screening and testing of materials such as particles and powders, they have obvious differences in working principle, structural composition, applicable materials, screening effect and application range.

1.Differences in working principle

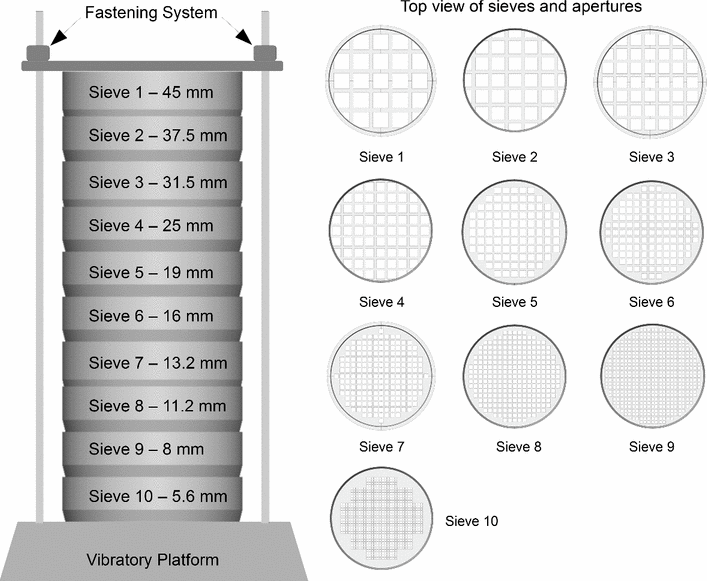

Ordinary test sieve vibrates the screen surface through mechanical vibration (such as vibration motor drive), drives the material to jump or slide on the screen surface, and the particles smaller than the sieve hole pass through the sieve to achieve classification. The vibration frequency and amplitude are fixed, and the screening is completed by the combined force of the material's own gravity and mechanical vibration, and the ability to disperse particles is limited.

Ultrasonic test sieve: On the basis of the ordinary test sieve, an ultrasonic vibration system (including ultrasonic power supply, transducer, screen, etc.) is superimposed. The ultrasonic energy is transmitted to the material through the screen, so that the material on the screen surface is subjected to high-frequency vibration (usually 20-40kHz). Ultrasonic vibration can effectively destroy the surface tension and adsorption force of the material, prevent particle agglomeration and screen clogging. The material is subjected to the dual effects of mechanical vibration and ultrasound on the screen surface, and the screening efficiency is significantly improved.

2. Differences in structural composition

|

Comparison dimension |

Ordinary test sieve |

Ultrasonic test sieve |

|

Image |

|

|

|

Core components |

Vibration motor, screen frame, screen |

Vibration motor, screen frame, screen, ultrasonic power supply, transducer, resonance ring |

|

Screen design |

Ordinary metal screen (such as stainless steel mesh) |

Special screen, the surface may be coated and needs to be matched with the ultrasonic system |

|

Additional function |

No special function |

Can be equipped with ultrasonic frequency adjustment, amplitude adjustment and other control systems |

|

Sealing |

General sealing design |

Usually a tighter sealing structure is used to prevent ultrasonic energy leakage |

3.Different characteristics of applicable materials

Ordinary test sieve: Applicable materials: materials with large particles (usually greater than 40 mesh, that is, the mesh size is greater than 0.425mm), good fluidity, and not easy to agglomerate, such as sand, ore, grain, etc. The requirements for screening efficiency are not high, or the material has no special physical properties (such as static electricity, hygroscopicity).

Ultrasonic test sieve: Applicable materials: fine particles or ultrafine particles (such as less than 325 mesh, mesh size less than 45μm), such as pigments, coatings, pharmaceutical powders, nanomaterials, etc. Materials that are easy to agglomerate, have high viscosity, and carry static electricity, such as wet powders, magnetic materials, carbon powder, etc., can be effectively dispersed by ultrasound to avoid clogging. High-precision screening requirements, such as accurate analysis of material particle size distribution in the laboratory, require that particles can pass through the mesh quickly and accurately during screening.

4.Comparison of screening effects

Ordinary test sieve

Screening efficiency: Good effect on coarse particles (such as >100μm), but fine powder (such as <20μm) is easy to clog the screen and needs to be cleaned frequently.

Precision: Affected by material characteristics (such as humidity, static electricity), repeatability may decrease.

Scope of application: Suitable for materials with larger particle size and better fluidity, such as sand, grain, chemical raw materials, etc. For fine particles, micro powders or materials that are easy to clog the screen, the screening effect is poor, the screen is easy to clog, and the screening efficiency is low

Ultrasonic test sieve

Screening efficiency: The efficiency of ultrafine powders (such as 1-50μm) is increased by 30%-50%, and the clogging rate is reduced by more than 80%.

Accuracy: Ultrasonic vibration can eliminate static electricity and agglomeration, improve classification accuracy, and is suitable for high-precision detection (such as particle size distribution analysis).

Scope of application: Specially used for ultrafine powders, materials that are easy to agglomerate (such as metal powders, medicines, food additives, ceramic powders, etc.), colloids and other difficult-to-screen materials. Ultrasonic vibration effectively prevents screen clogging, increases screening accuracy, and significantly improves screening efficiency and powder output rate.

Related parameters

|

Model |

Name |

Unit |

Parameter |

|

01 |

Screen frame |

Layer |

1~8 |

|

02 |

Screen frame diameter |

mm |

Φ200 |

|

03 |

Screening particle size |

mm |

0.025~3 |

|

04 |

Noise |

dB |

less than 50 |

|

05 |

Amplitude |

mm |

0~3 |

|

06 |

Vibration frequency |

times/min |

1440 |

|

07 |

Dimensions |

Length, width and height |

350:350:300+N*50 |

|

08 |

Power supply |

V;HZ |

220;50 |

|

09 |

Machine weight |

Kg |

36 |

|

10 |

Vibration motor |

Power |

0.12KW |

5.Different application ranges

Ordinary test sieves are commonly used for conventional screening and detection in the fields of mining, metallurgy, building materials, and chemical industry. They are used for preliminary particle size classification of materials, and the screening accuracy requirements are relatively low. Ultrasonic test sieves are more suitable for screening and detection of high-precision and fine materials such as nanomaterials, pharmaceutical powders, ceramic powders, and food additives. It is also widely used in electronic materials (such as electronic paste, battery powder), laboratory research and other fields to meet the needs of accurate analysis of material particle size distribution.

In short, the choice of test sieve depends on the characteristics of the material to be screened and the requirements for screening efficiency and accuracy. For ordinary particles that are not easy to agglomerate, ordinary test sieves can meet the needs. For fine powder, easy to agglomerate, and highly adsorbable materials, ultrasonic test sieves are a better choice.