Product introduction and application of 450 filter sieve

Tuesday February-25 2025 11:11:02

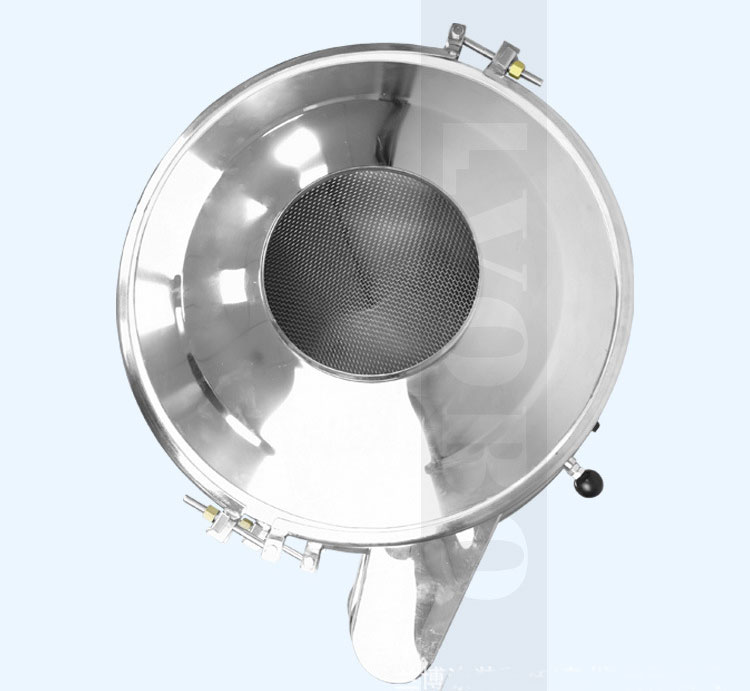

What is 450 filter sieve?

The 450 filter sieve is a single-layer filter sieve with a fixed model. It is small and does not take up space and is easy to carry. The weight of the machine is less than 50kg. It is used to remove impurities from powder or slurry materials with large particle content and good fluidity. It is a single layer, and compared with ordinary vibrating screens, the screen frame is designed to be heightened to prevent liquid from splashing during the screening process.

Product introduction of 450 filter screen

①High quality: The part in contact with the material is made of 100% stainless steel 304, which is safe and hygienic.

②Wide range of uses: The machine is exquisitely designed and suitable for any slurry, mucus and powder.

③Unique structure: Four spring locking frames, no leakage, easy to replace the screen and clean.

④Smooth screening: The machine is fully enclosed, the mesh is not blocked, there is no powder flying, and it can reach 400 meshes.

⑤Small footprint: The machine is small in size, light in weight, easy to move, and durable.

| Product Name | 450 Filter Screen | Keywords | Vibrating Screen |

| Engine | Vertical Vibrating Motor | Usage | Filter |

| Function | Screening, Separation, Sorting, Screening | Noise | Low Noise |

| Cleaning System | Bounce Ball | Warranty | 1.5 Years |

| Quality | Advanced Technology | Weight | 50 kg |

| Voltage | 380V/Customized | Dimensions (L*W*H) | 500*500*660 mm |

| Applicable Industries | Manufacturing Plants, Food and Beverage Plants, Farms, Home Use, Energy and Mining | ||

What is the application of 450 filter sieve?

The regular screen mesh of 450 filter sieve is the finest 400 mesh, and special mesh design can be carried out. According to the different conditions of screening materials, the screening output is 400-1200 kg/h. The following are the filtration conditions of some common materials and filter the output table:

| NAME | UNIT | Parameters | |

| Standard sieve frame layer number | s | 1 | |

| Screening size | mm | 0.038-5 | |

| Noise | dB | ≤85 | |

| Amplitude | mm | ≤5 | |

| Motor | Voltage | V | 380 |

| Rotaing speed | rpm | 1450 | |

| Power | kw | 0.18 | |

450 filter sieve can be widely used in geological, chemical, cement, medicine, research and production laboratories and other departments of scientific research and production test.

| materials | number of stitches | Yield |

| spray paint | 325 mesh | 1200L/h |

| flour | 30 mesh | 700kg/hour |

| juice | 40mesh-80mesh | 6-10 cubic meters/hour |

| pigment | 100-200 mesh | 500kg/hour |

| battery powder | 100mesh, 120mesh | 600kg/hour |

| Pomegranate juice | 100 mesh | 5 tons/hour |

| paint paint | 450 mesh | 800kg/hour |

| oat | 10 mesh | 800kg/hour |

Advantages of 450 filter sieve in application

1. Wide applicability, it can remove impurities from almost all powder and liquid materials with good fluidity, and it can penetrate the net quickly.

2. The heightened design of the sieve frame prevents powder and liquid from splashing during the sieving process, causing no pollution or waste.

3. Tight welding, anti-seepage treatment, motor waterproof grade IP54, safe operation, no leakage of sieving liquid.

4. The model is small and compact, and a trolley can be added for easy movement, and it can be easily operated by a single person.

Pre-sales service and after-sales service of 450 filter screen products

Pre-sales service

1. Provide technical consulting services to customers.

2. We can provide accurate quotations according to customers' models or drawings.

3. If necessary, you can send drawings and we can help you design the entire production line according to your model.

After-sales service

1. 24-hour online service and quick response within 12 hours.

2. The quality warranty period is 12 months from the date of shipment.

3. Regular tracking and accessories supply, and effective handling of customer feedback.

4. Provide assembly instructions, technical data and related soft copies or videos to ensure that customers can install and debug by themselves.