Maintenance and cleaning tips for laboratory test sieve

Tuesday February-25 2025 09:54:42

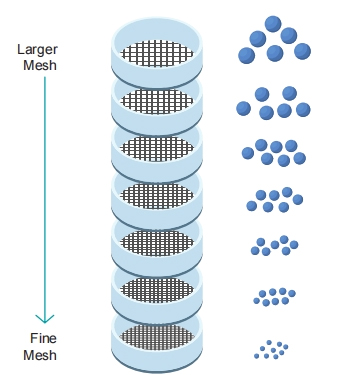

From the academic point of view of actual use scenarios, compared with other types of sieves, laboratory test sieve has higher requirements for the accuracy of mesh size, consistency of sieve frame specifications, and nestability.

Therefore, pay attention to the maintenance and cleaning of the laboratory test sieve. This article mainly introduces how to maintain and clean the laboratory test sieve in detail.

How to maintain the laboratory test sieve?

1. Regularly check the condition of the screen

It is one of the most basic maintenance to regularly observe whether the screen of the laboratory test sieve is worn or torn. The visual inspection of the screen should include the following aspects:

Mesh deformation or mesh deformation

Put the laboratory test sieve in a place with sufficient pipelines, and observe whether there is any depression or deformation on the mesh surface. The deformation of the mesh surface will affect the shape of the mesh, which will cause deviations in the test and analysis results during sample testing.

Scratches on the screen

The finer mesh of the laboratory test sieve also means that it is easier to break. If there are scratches on the screen, it is very likely to cause the tear of the screen.

Cracks or warping of the screen frame

The sieve frame provides a hand-held part and a sample holding space for the laboratory test sieve. If you find that the edge of the sieve frame is warped or cracked during inspection, please stop using it, so as not to affect the sieving effect or scratch the operator during sieving .

2. Correct screening

When using the laboratory test sieve, make sure not to use it for arbitrary sieving, use it according to the rules, and keep your sieve in the best condition.

Do not apply external pressure to force the sample through the sieve.

The sample volume for a single treatment should be moderate, and should not be too heavy or overfilled to avoid clogging the screen or affecting the free flow of the sample on the screen.

3.Clean after use

What utensil should be used to clean the laboratory test sieve?

The laboratory test sieve should be cleaned periodically with a soft brush and gentle circular motions. You need to make sure no bristles get stuck in the mesh after cleaning. Technicians should be careful not to press too hard on the mesh to remove stuck particles, and should not use sharp objects to remove blockages that could deform or break the mesh.

laboratory test sieve cleaning brush

These brushes are specially designed for cleaning and maintaining all test sieves. When used properly, they will not damage or hinder the performance or quality of the screen.

How do you clean a laboratory test sieve?

Gentle Brushing: After each use, gently brush the sieve to remove all sample material. Use gentle circular motions to brush the underside of the mesh, applying gentle pressure to remove particles.

Tap: Use the wooden handle of the brush to tap the sieve frame to help remove particles. Be careful not to deform the sieve frame.

Use Warm Soapy Water: Clean the sieve using a warm soapy water solution, carefully brushing the bottom to remove particles. For finer mesh sieves, consider using an ultrasonic cleaner as it is very effective. If using an ultrasonic cleaner, submerge the sieve in a solution of water and detergent. Ultrasonic agitation will help remove particles.

Close Inspection: Regularly inspect fine mesh sieves against a backlit or white background to identify any damaged openings or separations around the perimeter.

1、Cleaning Tips for Laboratory Test Sieves

Make sure the lab test sieves are properly cleaned and free of any residue before storage. It is also important to dry the lab test sieves to avoid discoloration and mold. Clean lab test sieves should be stacked and stored in a safe place such as a cabinet.

①Turn the sieve of the lab test sieve over and place it over a pan to collect the dislodged particles.

②Use a lab test sieve cleaning brush to gently brush the underside of the mesh in a circular motion.

③After brushing, gently tap the sides of the sieve frame to remove particles inside.

④Rinse the sieve with a warm, mild detergent solution.

⑤Dry the sieve by air drying.

2、Notes on Laboratory Test Sieve Cleaning Tips

| Precautions | Detailed instructions |

| Avoid force | Do not use tools or compressed air to force particles out of the opening. Excessive force may damage the sieve |

| No solvents | Avoid using solvents as they may damage the protective paint coating on some sieve frames |

| Avoid acidic solutions | Avoid acidic solutions during cleaning as they can change the wire diameter, widen the opening, weaken the wire weave, and ultimately affect the accuracy of the sieve |

| Brushing sieves finer than 45μm | For these sieves, ultrasonic cleaning can be chosen instead of brushing |

| Worn or damaged sieves | If the sieve is found to be worn, loose, or damaged, stop using the sieve. Check the sieve regularly to ensure that the sieve cloth is free of defects |

| Do not attempt to repair | Do not attempt to repair small holes or cracks. If such damage is found, it is best to replace the sieve |

| No dishwasher | Do not attempt to clean the test sieve in a dishwasher or dry it in an oven. This will damage the test sieve |

| No pressurized air | Do not use pressurized air to clean the test sieve as this will damage the test sieve |

3、What are the key indicators that a laboratory test sieve needs cleaning?

The easiest way to tell if a lab test sieve needs cleaning is by visual inspection. Over time, you will notice that the sieve openings become clogged with sample material buildup. This is especially true when dealing with particles of similar sizes and particles that are considered soluble in water. If you are unable to visually see the buildup of material throughout the test sieve, especially when using finer mesh sieves, you will begin to see anomalies in your sieve analysis results. More specifically, you will see that the sieves that need cleaning are producing a higher than average retention percentage.

Maintenance of laboratory test sieves, including regular cleaning and proper storage, is essential to prevent material buildup and ensure accurate results in laboratory work. Maintaining the integrity of these precision instruments will undoubtedly help improve the reliability and consistency of research and testing processes.One of the most common mistakes when cleaning laboratory test sieves is using an inappropriate tool to remove particles. Often, an object larger than the mesh opening is used, causing the mesh to tear or stretch. Additionally, excessive brushing force can damage the mesh and frame, especially those with finer mesh counts.