1. High-alloy stainless steel is used, which has strong corrosion resistance and is easy to clean.

2. It can effectively analyze and process the particle powder sample of 20μm~125mm, and can realize extremely fine mesh through the screen electroforming technology.

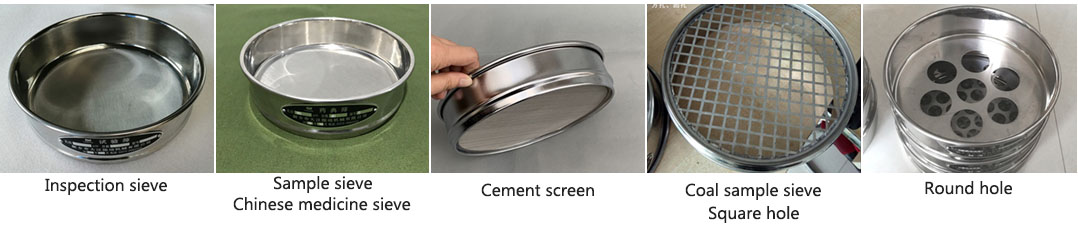

3. A perforated plate sieve with square or round holes can be used instead of wire mesh. Orifice sieves with square holes are down to 4mm and round holes down to 1mm.

4. In line with the international standard ISO3310-2:1990 R20/3, R20, R40/3 series.

5. The frame wall of Round Sieve is made of stretched and polished SUS304 stainless steel, smooth and firm, with a wall thickness of 0.6mm.

6. The screen mesh and the standard screen frame are fixed by welding, which will not loosen and shake, and can withstand high temperatures below 300 degrees.

Stainless steel round sieve

Brass material round sieve

Nylon material round sieve

Stainless steel round sieve

Stainless steel is the most common round sieve material, 304 or 316L stainless steel can be selected, it is widely used, and there are no special restrictions and requirements. There are square hole, round hole, metal woven mesh and other hole type standards.

The basic size of the mesh is 2.36mm-0.038mm, which conforms to the international standard ISO3310-1:1990R20/3, R20, R44/3 series.

Brass material round sieve

The round sieve made of brass metal and copper wire woven mesh has good wear resistance and chemical resistance, and is used to detect and analyze some samples with high hardness and special chemical properties.

The basic size of the mesh is 2.36mm-0.038mm, which conforms to the international standard ISO3310-1:1990R20/3, R20, R44/3 series.

Nylon material round sieve

The screen frame and screen are made of PVC nylon round sieve, no metal components, nylon material has good elasticity, usually nylon woven screen, can be used to screen some materials that are easy to react with metals, such as: oxidation Zirconium, phosphors and some special additives.

The basic size of the mesh is 2.36mm-0.038mm, which conforms to the international standard ISO3310-1:1990R20/3, R20, R44/3 series.

| Name | Specification |

| New standard sand and gravel screen (φ300, 7 pieces/set + bottom cover) | 9.50, 4.75, 2.36, 1.18, 600μm, 300μm, 150μm |

| New standard gravel sieve (φ300 12pcs/set+bottom cover) | 2.36, 4.75, 9.50, 16.0, 19.0, 26.5, 31.5, 37.5, 53.0, 63.0, 0.75, 90.0mm |

| Pavement base aggregate screen (φ200, 300, 11 pcs/set + bottom cover) | 0.075, 0.25, 0.5, 1, 2, 5, 10, 20, 30, 40, 50 |

| Asphalt aggregate square hole sieve | 0.075, 0.15, 0.3, 0.6, 1.18, 2.36, 4.75, 9.5, 13.2, 16, 19, 26.5, 31.5, 53mm |

| New standard square hole sieve (φ200×50mm6pcs/set) | Iron plate square hole: 4.75, 9.5, 13.2, 16, 19, 26.5, 31.5, 37.5, 53mm |

| Wire mesh square hole: 0.075, 0.15, 0.3, 0.6, 1.18, 2.36 | |

| Frame punching sand screen (casting screen) φ200 (11pcs/set) | 3.35, 1.7, 0.85, 0.6, 0.425, 0.3, 0.212, 0.15, 0.106, 0.075, 0.53mm |

| Pavement square hole aggregate screen | 80, 60, 50, 40, 30, 25, 20, 10, 5, 2, 1, 0.5, 0.2, 0.075mm |

| Asphalt pavement aggregate screen (φ200, 300, 15 pcs/set + bottom cover) | 0.075, 0.15, 0.3, 0.6, 1.18, 2.36, 4.75, 9.5, 13.2, 16.0, 19.0, 26.5, 31.5, 37.5, 53mm |

| Sand and gravel screen φ200×50(8pcs/set) | Iron plate round hole 10, 5 |

| Square hole copper mesh 2.5, 1.25, 0.63, 0.315, 0.16, 0.08 | |

| Stone sieve φ300×70mm (12pcs/set) | 2.5, 5, 10, 16, 20, 25, 31.5, 40, 50, 63, 80, 100mm |

| Lime sieve (φ200 5pcs/set+bottom cover) | 0.125, 0.71, 0.9, 5, 20 |

| New Standard Pharmacopoeia Sieve φ200×50mm (9pcs/set) | 2, 0.85, 0.355, 0.25, 0.18, 0.15, 0.125, 0.09, 0, 075mm |

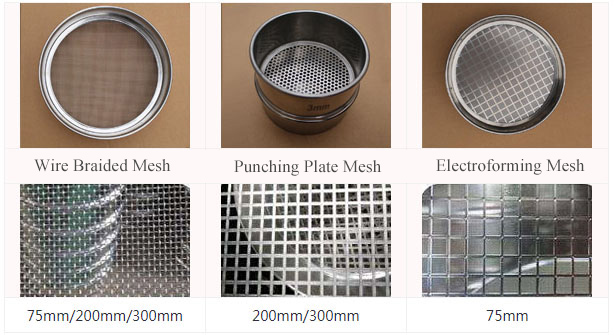

Metal wire mesh: It is produced by the national standard GB/T6003.1-1997, the basic size of the mesh is 2.36mm-0.038mm, in line with the international standard ISO3310-1: 1990 R20/3, R20, R40/3 series, screen mesh Materials are brass, tin bronze, stainless steel.

Metal perforated plate: The national standard GB/T6003.2-1997 is adopted, and it conforms to the international standard ISO3310-2: 1990R20/3, R20, R40/3 series. There are two kinds of meshes, round holes and square holes, from 0.2 to several hundred millimeters.

Electroforming mesh: mainly used in high-precision occasions, each mesh can be within the average error range.

| Serial number | name | unit | data | |

| 1 | Standard screen body | Floor | 8 | |

| 2 | Screen diameter | mm | φ200φ2100φ275 | |

| 3 | Screening size | mm | 0.038-3 | |

| 4 | noise | dB | ≤50 | |

| 35 | Feeding amount (one-time) | g | ≤200 | |

| 6 | amplitude | mm | ≤5 | |

| 7 | Motor | Voltage | V | 220 |

| Rotating speed | r/min | 1420 | ||

| power | KW | 0.125 | ||

| 8 | Dimensions | mm | 360×300×736 | |

| 9 | Overall quality | Kg | 25 | |

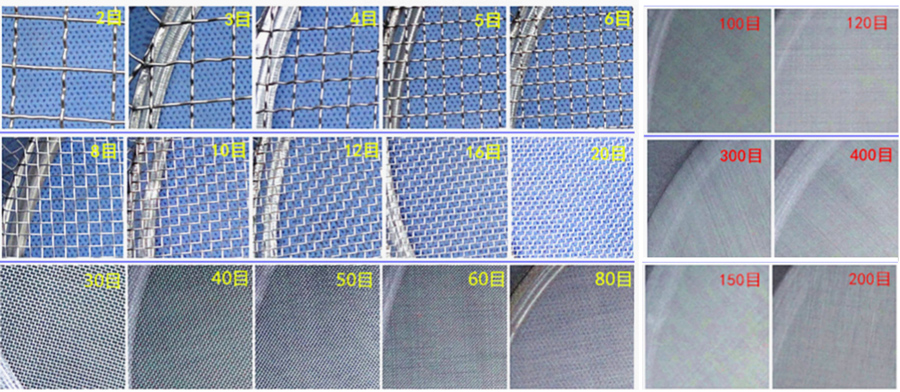

| Mesh number (mesh) | Aperture | Mesh number (mesh) | Aperture | Mesh number (mesh) | Aperture | Mesh number (mesh) | Aperture |

| 5 | 4mm | 40 | 0.45mm | 180 | 88μm | 325 | 34μm |

| 6 | 3.2mm | 50 | 0.355mm | 190 | 80μm | 360 | 40μm |

| 8 | 2.5mm | 60 | 0.3mm | 200 | 76μm | 400 | 38.5μm |

| 10 | 2mm | 70 | 0.25mm | 220 | 70μm | 500 | 30.8μm |

| 12 | 1.6mm | 80 | 0.2mm | 240 | 65μm | 600 | 25μm |

| 14 | 1.43mm | 100 | 0.15mm | 250 | 63μm | 800 | 15μm |

| 16 | 1.25mm | 120 | 0.125mm | 260 | 57μm | 900 | 10μm |

| 18 | 1mm | 140 | 0.105mm | 280 | 55μm | 1000 | 8μm |

| 20 | 0.9mm | 150 | 0.1mm | 300 | 50μm | 1200 | 5μm |

| 30 | 0.6mm | 160 | 97μm | 320 | 48μm | Bottom cover | Nonporous |

round sieve is a kind of laboratory sieving equipment. There are two options of manual sieving and machine sieving. Machine sieving can use a sieving machine instead of manual sieving. The sieving machine has an automatic timing function of 0-99 minutes, which can Ensure the accuracy and reliability of analysis between sample groups, saving time and manpower.

1. Dry sieving: It is used to process dry or free-falling high-flowing particles and powder samples. These samples can flow and separate by themselves, and are suitable for processing powder particles such as chemicals, food, and medicine.

2. Wet sieving: use liquid substances to process samples that are difficult to pass through the screen or are solid. The method is to apply liquid (usually water) to the test sample to make the fine particles pass through the sieve, while grading and agglomerating, and then Samples are dried and evaluated, and wet sieving is suitable for samples with a high concentration of fine particles or samples where the particles are not easily broken by mechanical shaking. Clays, such as clay or silt, for example, can clump together to form larger particles that cannot pass through the mesh.

| Materials | Number of stitches | Materials | Number of stitches | Materials | Number of stitches |

| Cassia | 14 mesh | Buckwheat | 12 mesh | Tenebrio eggs | 12 mesh |

| Insect droppings | 30 mesh | soybean | 4-5 mesh | green beans | 10 mesh |

| rice | 12-14 mesh | rice flour | 30-40 mesh | corn flour | 30-40 mesh |

| flour | 50-60 mesh | grains | 40-50 mesh | sesame millet | 22-24 mesh |

| Fried Chicken Noodles | 20-30 mesh | mung bean powder | 40-50 mesh | Sesame powder | 40-50 mesh |

| Panax notoginseng powder | 100-120 mesh | pine pollen | 100-120 mesh | Chinese medicine powder | 40-50 mesh |

| Oral Chinese medicine powder | 60-80 mesh | Chinese medicine mask | 80-120 mesh | Pearl powder | 120-150 mesh |

| dregs | 60-150 mesh | soy milk | 80-120 mesh | Honey | 80-120 mesh |

| Soup dregs | 120-150 mesh | tea water | 120-150 mesh | edible oil | 150-200 mesh |

Chemical products: feed silicone, glass, glass fiber, polyamide, paint

Food: rice bran, cereals, corn, sesame, sugar, milk

Medicine: baking soda, Chinese medicine

Metallurgy: cement, aluminum powder, ore, lime, kaolin

Ceramics: ceramic slurry, clay, volcanic rock, coke, tar