Application of Tumbler Screen in spice screening

Friday February-28 2025 10:26:57

What is Spice Tumbler Screen

The Spice Tumbler Screen is entirely made of stainless steel (SS304 or 316L) with a compact structure, which is very suitable for small spaces where material receiving and screened product discharge are close to each other, for screening spices and ensuring safety. Tumbler Screens are easy to arrange, just place them at the outlet of a discharge hopper, grinder, mixer, etc.

How does the application of tumbler screen in spice screening work?

Application of Tumbler Screen in spice screening can produce horizontal and throwing three-dimensional rolling motion. This principle is similar to manual screening. The material moves in an involute spiral on the screen surface, and the screened material is evenly distributed on the entire surface from the center to the periphery. The radial inclination angle makes the screening material move outward from the center, and the tangential inclination angle makes the material move in a circular motion, thereby realizing the spiral motion. The fine particles pass through the center, while the coarse particles move outward in a circular pattern at the periphery and exit from the outlet.

Advantages of Tumbler Screen in Fragrance Grading or Impurity Removal

1. Use 304 or 316L food/pharmaceutical grade materials, which can meet the hygienic standards required for spice screening.

2. The processing method imitating artificial sieving can make the spices be sieved more carefully, and increase the mesh surface contact frequency and penetration rate of the spices.

3. More forms of mesh surface cleaning methods (bouncing ball, roller brush, ultrasonic deblinding) can be selected, which can be based on the conditions of the spices being processed (humidity, irregular particles, oiliness, light powder, etc.) and the actual machine Purchasing budget for design.

4. Sealed structure. The Tumbler Screen adopts a fully enclosed structure, which prevents the spice powder from leaking out and prevents external pollution from entering, which meets the hygienic requirements.

6. Ease of maintenance. The vibration part of Tumbler Screen has been modularized and standardized, and can be replaced quickly as a whole, which can greatly shorten the maintenance time and improve the screening efficiency.

、

、

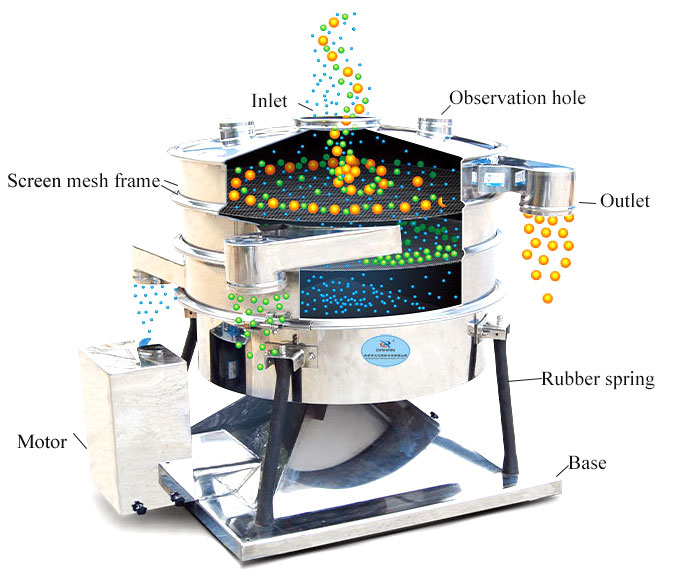

Application of Tumbler Screen in spice screening Structures

Application of Tumbler Screen in spice screening usually consists of a dust cover, feed port, screen, screen, mesh frame, discharge port, and other parts.

Feed port: The design of the buffer plate allows the material to flow evenly into the screen surface, and the material can be inspected through the viewing port.

Dust cover: It limits the material's movement range and protects the machine and the surrounding environment from dust.

Vibration motor: The vibration motor makes the vibrating screen vibrate in multiple planes. This movement increases the speed of the material passing through various sieves.

Shock-absorbing spring: Let the entire upper part of the machine vibrate freely, it helps to minimize power consumption, prevent any vibration from being transmitted to the floor, and reduce noise.

Screen: Maintains tension and makes it easier for the material to move in the direction of vibration. This can be horizontal or vertical. One machine can achieve the separation of multiple materials at the same time.

Discharge port: The discharge port size can be designed according to needs, and the discharge speed through the valve can be adjusted according to needs.

Tumbler Screen maintains a uniform tensile force on the entire screen surface to ensure that the system has a very high screening accuracy for spices, and reduces the strong impact on the screen, which increases the life of the screen and reduces maintenance costs.