Advantages and limitations of sieve shaker

Wednesday March-05 2025 17:30:01

As a laboratory sample sieving tool, sieve shaker is able to achieve accurate sieving is his most important ability. Based on the standard sieve shaker, this article introduces the advantages and limitations of the sieve shaker:

What are the principles of a sieve shaker?

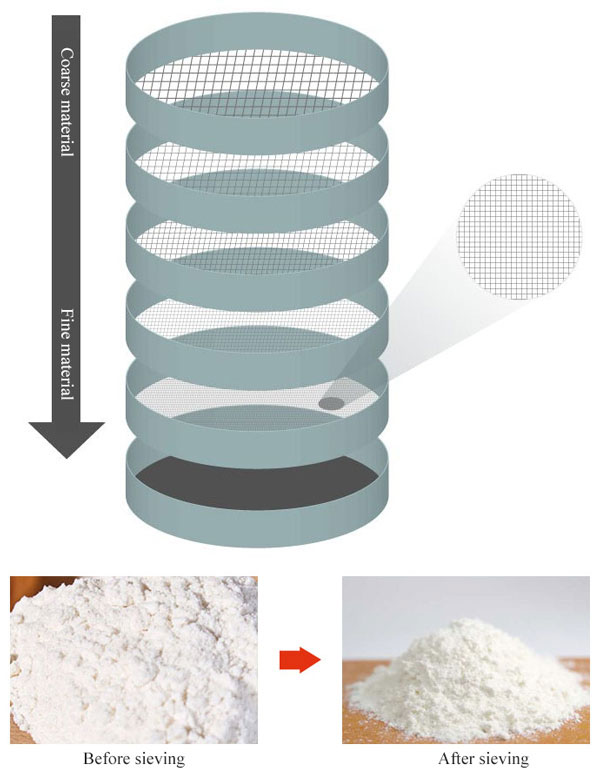

Sample loading: Place the material to be analyzed on top of the sieve stack. Depending on the application, the sample can be powder or particle.

Vibration motion: The screening machine is driven by an electric motor, generating vibration motion. The amplitude and frequency of this movement are usually adjustable and can be flexibly adjusted according to the specific material being tested.

Particle separation: With the vibration of the vibrator, particles will pass through the sieve. Larger particles will remain on the upper sieve, while smaller particles will pass through the lower sieve. This process continues until all particles are classified according to their size.

Data collection: After shaking, collect particles from each sieve and measure the weight of the material retained on each sieve. This data is used to determine the particle size distribution of the sample.

What are the advantages of sieve shaker?

Sieve shaker is very convenient to use, and users can easily and effectively use them for particle separation. The screening process requires less time, which is a major advantage of the screening machine.

Efficiency: Rapid and efficient separation of particles based on size.

Consistency: Provides consistent and reproducible results when operated under controlled conditions.

Versatility: Can handle a wide range of materials, including powders and granular substances.

Ease of Use: Relatively simple to operate, making it accessible for routine quality control procedures.

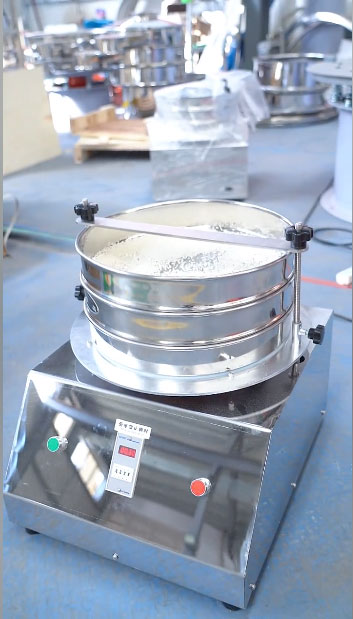

1. The operation is simple and does not require additional learning costs.

2. It has a 0-99 minute timing device, which can be automatically turned on or off to ensure accuracy and repeatability.

3. The machine has a compact structure and takes up little space, and can be used on the laboratory operating table.

4. It can realize the sieving treatment of most particles to powder samples.

5. It is made of all stainless steel, which is more hygienic and durable, and does not cause corrosion or iron filings due to rust.

6. Compared with manual analysis, it is more efficient and more accurate, saving time and effort.

7. The purchase cost of the sieve shaker is low and does not require excessive expenses.

What are the limitations of sieve shaker?

For particles smaller than 100 millimeters, the accuracy of dry screening is not as good as wet screening. In addition, screening studies infer that all particles are circular, but this is not the case. In addition, enlarged or flattened particles cannot be successfully studied using a sieve.The device is unable to successfully separate particles smaller than 50 millimeters. If the size is further reduced, errors may occur.

1. Affected by volume, the sample size of a single sieve by sieve shaker should not be too large.

2. The sieve shaker sieve assumes that the samples analyzed are all round or spherical, which is not entirely correct.

3. Elongated or flat particles cannot be analyzed using sieve shaker.

4. Samples that are too fine will be difficult to analyze accurately.

5. Most screens are fragile and require careful handling and maintenance.

Particles up to 50 um size can be obtained.

If the powder to be analyzed is moist then the sieve apertures get clogged due to which the sieving efficiency decreases.

As the particles collide with one another, it may lead to attrition and the particles may be further size reduced. This may give false results.