There are two forms of conventional products of lab sieve shaker, the difference of product form mainly lies in the difference of sieving form

Standard lab sieve shaker

The number of screen frames that can be placed: 1-8 layers

Measuring range: 0.025mm~3mm

Timing range: 0-99min

Standard lab sieve shaker: suitable for the detection of laboratory powder, granule and liquid materials, and can be equipped with an ultrasonic system

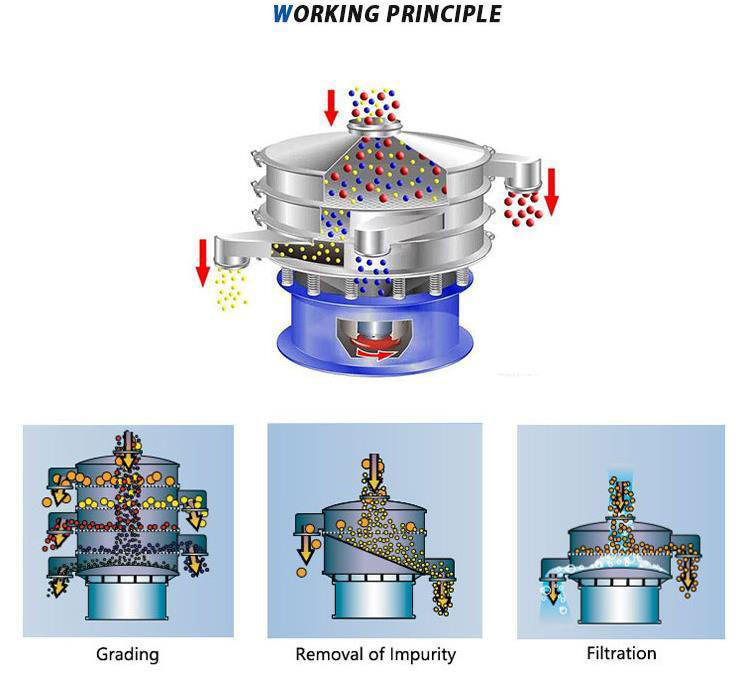

With the vertical motor as the power source, it is transmitted to the sample through the sieve tray for grading.

clapping lab sieve shaker

The number of screen frames that can be placed: 1-8 layers

Measuring range: 0.025mm~3mm

Timing range: 0-99min

clapping lab sieve shaker: suitable for inspection of ordinary abrasive grain size composition, superhard material production classification and material size composition inspection

In addition to the standard circular shaking, a clapping longitudinal motion is added to obtain more fine samples.

| According to the material | ||

| Stainless Steel Standard Sieve Shaker | Brass Sieve Shaker | Nylon Standard Sieve Shaker |

| 75/100/200/300/400mm | 200/300mm | 200mm |

| Common Standard Sieve Shaker material, resistant to wear and corrosion, no rust, and high hygiene standards. | Good ductility and is used for special sample screening. It is softer than stainless steel. | Non-magnetic material and metal material, used for sieving of special fibers, chemical additives and samples with active properties. |

| According to the screen | ||

| Metal braided wire mesh | Punching plate screen | Electroforming screen |

| The finer mesh type is mostly made of metal wire, the hole type is square, and the mesh number is 0.02mm-2.36mm | Most of them are punched from stainless steel. The mesh shape is round or square, and the shape can be customized. It is mostly used for soil, sand and other hard, granular or block samples | The most dense form of sieve mesh, the mesh number is 75μm-5μm, which needs to be supported by a mesh frame, which is suitable for sieving light, fine and small samples. |

The lab sieve shaker is used in the sample screening work in the laboratory. It has a timing function of 0-99 minutes and can prevent 1-7 layers of sieve frames. sieves of different diameters.

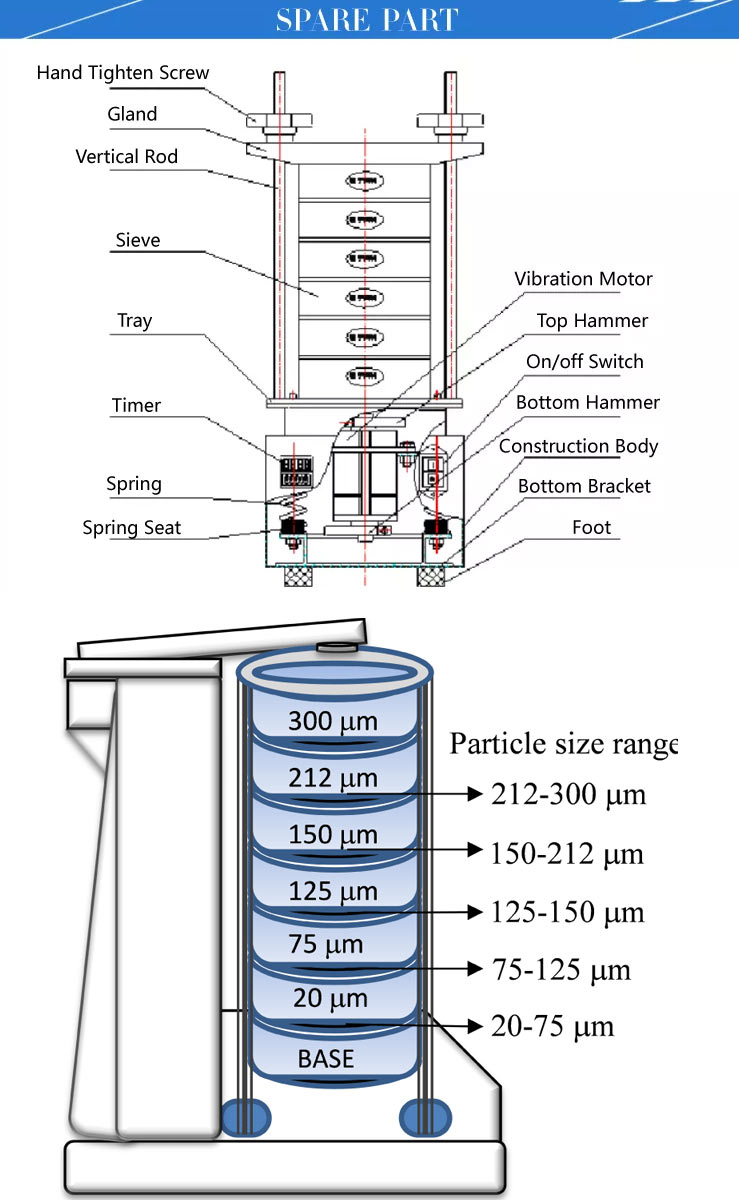

1. The adjustable screw and handle can flexibly adjust the number and height of the sieve frame that can be accommodated, and at the same time ensure that it is fixed firmly

2. There is no burr in the cross section, which meets the safety operation standard

3. A single machine weighs only 45kg, small in size, easy to carry and operate, and does not take up space

4. During the screening process, the machine produces vertical and side-to-side shaking motions, and the screening effect is good and the precision is high

5. 0-99 minutes timer relay can ensure the accuracy and repeatability of the experiment

The lab sieve shaker is mainly used in the internal laboratories of universities/research institutes/enterprises, and cooperates with experimental sieves for particle size analysis and detection of granule and powder materials. With 0-99 minutes automatic timing device, it can realize timing shutdown, fully automatic screening while ensuring the controllability and accuracy of sample analysis. It can be used in various fields such as geological research, chemical medicine, biological research, etc.

| Serial number | name | unit | data | |

| 1 | Standard screen body | Floor | 8 | |

| 2 | Screen diameter | mm | φ200φ2100φ275 | |

| 3 | Screening size | mm | 0.038-3 | |

| 4 | noise | dB | ≤50 | |

| 35 | Feeding amount (one-time) | g | ≤200 | |

| 6 | amplitude | mm | ≤5 | |

| 7 | Motor | Voltage | V | 220 |

| Rotating speed | r/min | 1420 | ||

| power | KW | 0.125 | ||

| 8 | Dimensions | mm | 360×300×736 | |

| 9 | Overall quality | Kg | 25 | |

lab sieve shaker is mainly composed of stainless steel sieve frame, sieve frame tray, adjustable screw, timing switch device, motor and base.

The motor provides power for the operation of the machine, and the screening time is set according to the material condition and the expected screening result. When the switch is turned on, the power device is transmitted to the sieve plate to drive the sieve to move.

According to the actual situation of the material and the requirements of particle size classification, select the screen frame with different meshes, place the screen frame on the tray, adjust the height of the tray, and carry out material screening.

During this process, the materials in the sieve frame are screened layer by layer by the large-aperture sieve, and are screened into the sieve frame layers with different meshes according to their own different particle sizes.

bismuth tungstate--500 mesh

sieve shaker for testing soil

how to use sieve shaker