| Vibratory Sieve Shakers | lectromagnetic Vibratory Sieve Shakers | Slap Vibratory Sieve Shakers | Ultrasonic Vibratory Sieve Shakers |

|

|

|

|

| Suitable for coarse material screening within 300 mesh | It solves the problem of dry sieving of ultrafine powder, which can be sieved to 20μm (635 mesh). | Suitable for coarse materials within 500 mesh, fast cutting, suitable for diamond powder, superhard material industry | High-precision powder within 500 mesh, not easy to block |

Vibratory Sieve Shakers are sieving instruments used for laboratory particle size analysis and testing, and can stack multiple 200, 300, 400mm test sieves. Vibratory Sieve Shakers provide accurate and repeatable sieving experiments for samples through motor vibration, with a timing function of 0-99min.

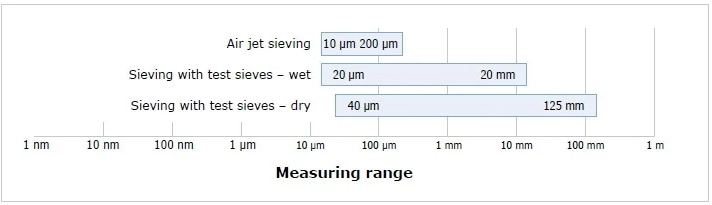

Suitable for dry and wet sieving.

Measurement range from 20 μm to 25 mm.

The screen frame is made of SUS304 stainless steel by stretching and polishing, the wall thickness is 0.6mm, the gloss is uniform, durable, and there is no magnetism.

Equipped with time relay control, it has excellent separation efficiency even in a very short screening time, and can be shut down regularly to ensure test repeatability.

The 3-D throwing motion ensures optimal use of the open sieve area and even movement of the sample across the entire sieve surface.

The screen mesh and the screen frame are fixed by soldering to prevent the problem of loosening and shaking, and can work stably at a temperature of >300 degrees.

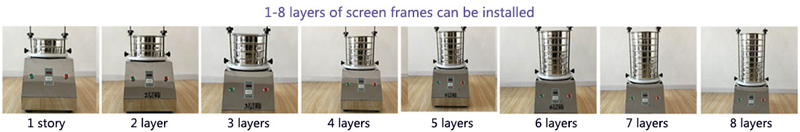

It can be installed with 8 layers of screen frame, which can precisely separate one kind of granular material into 2~8 particle segments at the same time.

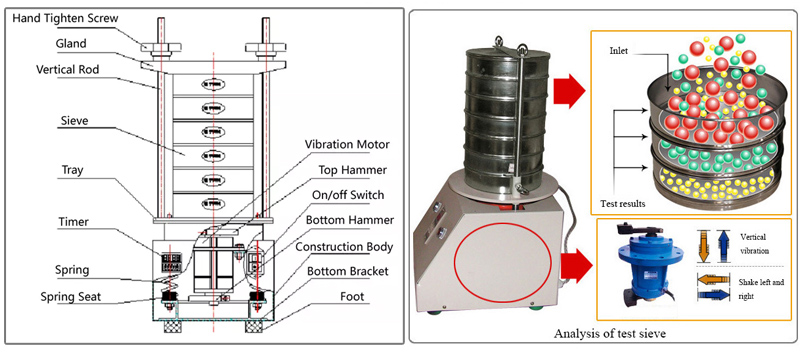

Vibratory sieve shakers use YZU vertical vibration motor as the vibration source of the whole machine, drive the upper vibrating plate to vibrate through the vibration motor, and then transmit it to the upper screen frame of the vibrating plate through the vibration plate, and then the screen frame needs to detect the mesh number. The material particles smaller than the sieve aperture are sieved to the lower sieve frame, so that only the same particle size remains in each layer of the test sieve, so as to achieve the separation of different particle sizes and determine the particle size composition of the material.

Once these questions are answered satisfactorily, the appropriate sieving method can be selected. Vibrating screen, wet screen vibrating screen or jet screen.

1.Vibratory sieving: Vibratory sieving allows the sample to move in three dimensions. The vertical throwing motion is superimposed with the circular motion. This mechanism distributes the particles evenly over the entire sieving surface and is thrown into the air, where they ideally change their orientation, allowing them to be compared to sieve openings of all possible sizes.

2.Wet sieving: use liquid substances to process samples that are difficult to pass through the screen or are solid. The method is to apply liquid (usually water) to the test sample to make the fine particles pass through the sieve, while grading and agglomerating, and then Samples are dried and evaluated, and wet sieving is suitable for samples with a high concentration of fine particles or samples where the particles are not easily broken by mechanical shaking. Clays, such as clay or silt, for example, can clump together to form larger particles that cannot pass through the mesh.

3.Jet Screening: To obtain a screen cut through an air jet screen, only one screen is used instead of a bunch of screens, and the screen itself does not move. Industrial vacuum cleaners create low pressure in the screen chamber. Intake air escapes at high speed from rotating slit nozzles below the screen and disperses particles, which can then be compared to the screen openings. When the particles hit the screen cover, they are not only redirected but also deagglomerated. Small enough particles are then transported through the screen and sucked out. They can also be collected in cyclones.

4.Dry sieving: It is used to process dry or free-falling high-flowing particles and powder samples. These samples can flow and separate by themselves, and are suitable for processing powder particles such as chemicals, food, and medicine.

| Items | Name | Unit | Data |

| 1 | Layers | layer | 1-8 |

| 2 | Diameter | mm | 75,100,200, 300 |

| 3 | Sieve frame | mm | 100, 200, 300, 400 |

| 4 | Noise | db | below 50 |

| 5 | Feeding Capacity (Once) | g | <200 g/ml |

| 6 | Amplitude | mm | <5 |

| 7 | Voltage | v | 220 v / customized |

| 8 | Power | kw | 0.125 |

| 9 | Overall Dimension | mm | 450*410*700 |

| 10 | Weight | kg | 35 |

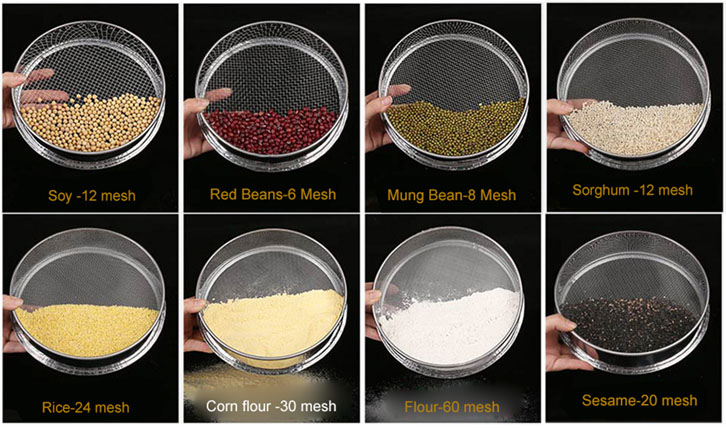

| Mesh number | Aperture ﹙㎜﹚ | Mesh number | Aperture ﹙㎜﹚ | Mesh number | Aperture ﹙㎜﹚ | Mesh number | Aperture ﹙㎜﹚ |

| 5 | 4 | 32 | 0.56 | 100 | 0.15 | 280 | 0.055 |

| 6 | 3.2 | 35 | 0.5 | 120 | 0.125 | 300 | 0.050 |

| 8 | 2.5 | 40 | 0.45 | 140 | 0.105 | 320 | 0.045 |

| 10 | 2.0 | 45 | 0.4 | 150 | 0.10 | 325 | 0.043 |

| 12 | 1.6 | 50 | 0.335 | 160 | 0.098 | 360 | 0.040 |

| 14 | 1.43 | 55 | 0.315 | 180 | 0.09 | 400 | 0.0385 |

| 16 | 1.25 | 60 | 0.3 | 190 | 0.080 | 500 | 0.030 |

| 18 | 1.0 | 65 | 0.25 | 200 | 0.074 | 600 | 0.025 |

| 20 | 0.9 | 70 | 0.224 | 220 | 0.065 | 800 | 0.020 |

| 24 | 0.8 | 75 | 0.2 | 240 | 0.063 | 1000 | 0.015 |

| 26 | 0.7 | 80 | 0.18 | 250 | 0.061 | 1250 | 0.010 |

| 30 | 0.6 | 90 | 0.16 | 260 | 0.057 | Bottom cover |

It is used in laboratories and quality inspection rooms to accurately analyze the particle size structure of particles and powder materials and test and analyze the liquid solid content. The screening accuracy is accurate and the efficiency is high.