What is the difference between ultrasonic vibrating screen and rotary vibrating screen?

Thursday February-16 2023 12:27:37

Ultrasonic vibrating screen and rotary vibrating screen many users at the time of purchase will ask what are the differences? Today Xiaobian is for you to briefly introduce the difference between ultrasonic vibrating screen and rotary vibrating screen as follows:

First, the screening accuracy is different

Screening accuracy is different, rotary vibrating screen can mainly screen 200 mesh powder materials or 500 mesh the slurry material, and ultrasonic vibrating screen is mainly for 500 mesh powder materials, slurry can screen 1200 mesh.

Two, different net cleaning device

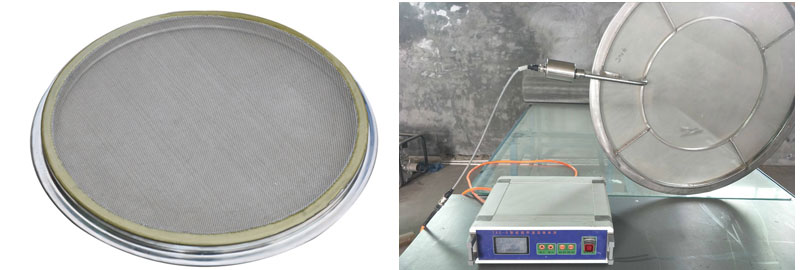

Network devices of different period of qing dynasty, vibration sieve qing network device to bounce the ball net, for some sticky, theater, adsorption, static electricity, light weight material is difficult to clean up that cause plugging problem, and the ultrasonic vibrating screen is used when the ultrasonic screening system (ultrasonic power supply, transducer, ultrasonic rack) open the ultrasonic vibrating screen after the screening system in the screen surface can form high frequency and low amplitude of ultrasonic vibration wave, thus effectively solve the above problem.

Three, ultrasonic vibrating screen and standard rotary vibrating screen model specific structure difference

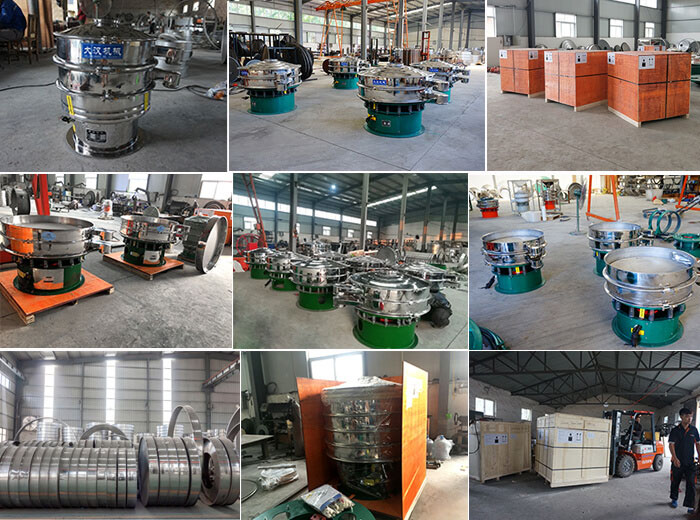

(1) the standard rotary vibrating screen model is composed of: top cover, small beam ring, mesh frame, sealing leather, punching plate, frame, large beam ring, bottom grid, vibration plate, drive motor, damping spring, bottom cylinder and other main accessories suitable for 200 mesh dry powder or 600 mesh slurry screening filtration; Its screening filtration efficiency is high, power consumption is small, does not occupy too much space, low noise, easy maintenance, etc., widely loved by users. Its decorate a style to compare flexible also.

Model (2) ultrasonic vibrating screen by: head, small clamps, ultrasonic rack, ultrasonic transducer, screen mesh, in the box, clamps, bottom, vibration plate, drive motor, damping spring, at the end of tube, ultrasonic main control box and other accessories composition mainly aims at below 200 mesh to 600 mesh sieving dry powder material, within the ultrasonic rack is by high-frequency ultrasonic pulse cleaning sieve, replace the standard vibration sieve machine by the simple device automatic qing qing tennis net, its high screening efficiency, no blocking by the network, the best separation equipment powder sieve divisions.

Four, screen distribution is different

The most direct difference between ultrasonic vibrating screen and rotary vibrating screen is that ultrasonic wave is more than a set of ultrasonic vibration screen producing device.

The sieving machine is exactly the same. The ultrasonic generator is composed of ultrasonic vibrating screen power supply and ultrasonic transducer. The transducer converts low-frequency current into high-frequency current, so as to screen materials with high-frequency vibration.

Above is Xiaobian for everyone to introduce the difference between ultrasonic vibrating screen and rotary vibrating screen as shown above, if you have any questions can consult Xinxiang Dahan vibration customer service personnel.