1. The sieving accuracy can reach more than 95%, and it can handle various particles, powders and liquids, and the output of sieving powder can reach 3300kg/h.

2. Easy to replace the screen, simple and convenient operation.

3. Do not block the mesh to prevent the powder from scattering, and the size of the filter is between 500 mesh or 0.028 mm.

4. Each layer of the screen box has a discharge port, can eliminate the completion of screening material, circular screen box design without dead Angle, can avoid hidden material.

5. Small size and easy to move.

6. The top layer of the screen is about 5 layers, but 3 layers are recommended.

The rotary vibrating screen uses a vertical motor as the vibration source, and eccentric hammers are installed at both ends of the motor to make the motor's rotating motion into a horizontal, vertical and inclined three-dimensional motion, and then transfer the motion to the screen. surface. The movement trajectory of the screen surface can be changed by adjusting the upper and lower phase angles.

The discharge port of the Rotary vibrating screen can be rotated 360° and adjusted with the lower end equipment. It can handle various particles, powders and liquid materials, and can be used in various fields such as food, industry, and agriculture.

Rotary vibrating screen with vacuum feeder

Rotary vibrating screen with screw conveyor

Rotary vibrating screen with belt conveyor

1. Food and medicine

Rotary vibrating screen filter juice

Rotary vibrating screen for screening coconut meat

Rotary vibrating screen for sifting flour

2. Chemical building materials

Rotary vibrating screen for sieving pigment powder

Rotary vibrating screen for sieving calcium powder

Rotary vibrating screen to filter chemical slurry

3. Agriculture

Rotary vibrating screen for screening corn

Rotary vibrating screen for screening feed

| Model | Power(kw) | Sieve diameter(mm) | Layers | Granularity(mm) | Voltage(v) | RMP(r/min) | Capacity(kg/h) |

| DH-400 | 0.18 | 350 | 1-4 | <10 | 380 | 1440 | 100 |

| DH-600 | 0.25 | 550 | 1-4 | <10 | 380 | 1440 | 500 |

| DH-800 | 0.55 | 750 | 1-4 | <10 | 380 | 1440 | 800 |

| DH-1000 | 0.75 | 920 | 1-4 | <10 | 380 | 1440 | 1400 |

| DH-1200 | 1.1 | 1120 | 1-4 | <10 | 380 | 1440 | 2100 |

| DH-1500 | 1.5 | 1420 | 1-4 | <10 | 380 | 1440 | 2600 |

| DH-1800 | 2.2 | 1720 | 1-4 | <10 | 380 | 1440 | 3300 |

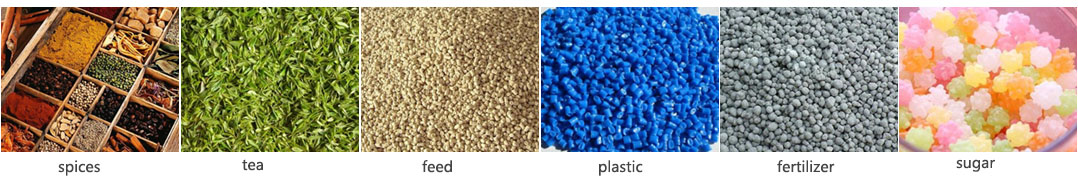

It is widely used in industries such as chemical industry, medicine, food and spices, tea, feed, plastic, fertilizer, sugar, salt and other renewable resources.

| Materials | Number of stitches | Materials | Number of stitches | Materials | Number of stitches |

| Cassia | 14 mesh | Buckwheat | 12 mesh | Tenebrio eggs | 12 mesh |

| Insect droppings | 30 mesh | soybean | 4-5 mesh | green beans | 10 mesh |

| rice | 12-14 mesh | rice flour | 30-40 mesh | corn flour | 30-40 mesh |

| flour | 50-60 mesh | grains | 40-50 mesh | sesame millet | 22-24 mesh |

| Fried Chicken Noodles | 20-30 mesh | mung bean powder | 40-50 mesh | Sesame powder | 40-50 mesh |

| Panax notoginseng powder | 100-120 mesh | pine pollen | 100-120 mesh | Chinese medicine powder | 40-50 mesh |

| Oral Chinese medicine powder | 60-80 mesh | Chinese medicine mask | 80-120 mesh | Pearl powder | 120-150 mesh |

| dregs | 60-150 mesh | soy milk | 80-120 mesh | Honey | 80-120 mesh |

| Soup dregs | 120-150 mesh | tea water | 120-150 mesh | edible oil | 150-200 mesh |

Vibrating sieve to sieve flour

Rotary vibrating sieve for screening metal powder

Ultrasonic vibrating screen mesh replacement