Vibro sifter is used in the pharmaceutical industry

Friday February-28 2025 13:59:44

Introduction of vibro sifter is used in the pharmaceutical industry

Vibro sifter is usually used in the pharmaceutical industry to sieve pharmaceutical raw materials such as Chinese medicine powder, raw material medicine, Chinese medicine formula granules, pellets, Chinese medicine pills, and Chinese medicine decoction pieces. The screening conditions and screening requirements of each raw material are different:

Name: Traditional Chinese Medicine Powder Mesh: 100-300 mesh Processing requirements: removal of impurities and oversized particles

Name: API Mesh: >150 mesh Processing requirements: uniform grading, removal of impurities Design: Ultrasonic system can be installed to improve screening accuracy

Name: Traditional Chinese medicine formula granules Mesh: 30-80 mesh Processing requirements: sieve to remove agglomerates, fine powder

Name: Pellet Mesh: 10-35 mesh Processing requirements: sieve to remove large particles and fine powder

Name: pills, decoction pieces Processing needs: remove damaged products, sieve powder

What is the working principle of a Vibro sifter vibro sifter is used in the pharmaceutical industry?

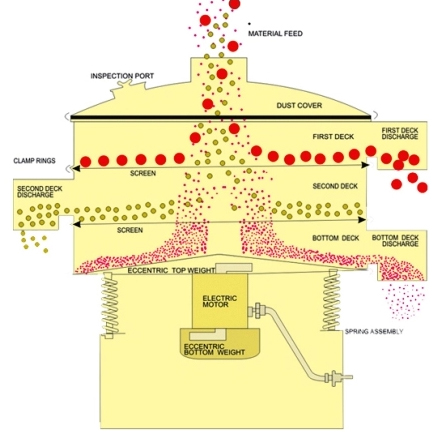

The vertical vibration motor of vibro sifter serves as the existing force source, with the eccentric weights installed at the upper and lower ends of the engine transforming the rotary motion of the motor into horizontal, vertical, and sloping three-dimensional action. Then, the vibratory movement is transmitted to the sifter surface for sieving.The moving track of the materials on the sifter surface can be modified by adjusting the phase angle of the upper and lower ends to fit the desired performance.

What is the purpose of vibro sifter in pharmaceutical industry?

Vibro sifter is widely used in the pharmaceutical and food industries to screen materials of different mesh sizes in pharmaceutical production.

1. Particle size analysis: Vibro sifter is used for particle size analysis of pharmaceutical raw materials. This ensures that the particles are within the required size range, which is crucial for the quality and stability of the final drug.

2. Screening and Separation: Vibro sifter is used to screen and separate pharmaceutical raw materials and formulations. This process ensures that only particles of the correct size are used during the production process.

3. Quality control:Vibro sifter plays a crucial role in the quality control process of drug production. By ensuring the use of only particles of the correct size, it helps maintain the quality and stability of the drug.

4. Ensuring drug quality and stability: By ensuring the use of only particles of the correct size, vibrating screens help maintain the quality of the drug. Consistent particle size is crucial for the efficacy of drugs as it affects the rate of dissolution and absorption in the body. The stability of drugs is also affected by particle size. Uniform particles are unlikely to separate or precipitate, which can affect the stability of the drug over time. The vibrating screen helps to achieve this uniformity, thereby improving the stability of the drug.

Advantages of vibro sifter in the pharmaceutical industry

The vibro sifter can sieve powders as fine as 500 meshes, and can meet the conventional needs of grading and sieving for traditional Chinese medicine powder and raw materials.

The number of screen layers can also be used flexibly. A single-layer screen can be used to filter and remove impurities from pharmaceutical raw materials, sieve out powder, soil, fiber, large-grained medicinal materials, and adhesive medicinal materials; The grading of pharmaceutical raw materials (up to six grades) can meet the application requirements of drugs with different characteristics.

Because some Chinese medicine pills and Chinese medicine formula particles will be wet or easy to stick, Chinese medicine powder and raw materials are too fine to cause network blockage, you can choose vibro sifter's silica gel (for food and medicine) jumping ball cleaning device to solve the network blockage caused by medicinal raw materials question.

Structural of vibro sifters used in the pharmaceutical industry

Vibro sifter is mainly composed of hopper cover, filter screen, metal mesh ring, oversized material outlet, screen material outlet, spring, control panel, engine and other components. The hopper cover can protect the raw materials being processed in the upper part of the machine from falling off during machine vibration. The filter element promotes material processing by producing a smooth surface finish. The metal mesh screening ring is the place where the metal wire mesh is bonded to the ring, and there is glue to help the metal wire mesh stick to the ring. After the screening process is completed, large particles are discharged through the oversized material outlet. The spring ensures that the machine moves hydraulically. When the machine vibrates and processes materials, the spring also holds the upper components of the machine in place. There are multiple buttons on the control panel that communicate signals to the machine about specific activities it should perform and display all programmed processes.

What is the use of vibro sifter in the pharmaceutical industry?

Vibro sifters are used in many industries for separating, filtering, and classifying powders and particles. They help ensure that materials meet size requirements and remove unwanted particles.

1.Pharmaceutical industry:It can remove particles that are too large or too small to ensure uniformity. In addition, it also helps to filter excipients and active ingredients.

2.Chemical industry:Vibro sifter is typically used to separate different grades of chemical powders and remove impurities from raw materials.

3.Raw material screening:Vibro sifter is used to screen raw materials before they are used in the production process. This ensures that only materials of the correct size and quality are used, which is crucial for the consistency of the final product.

4.Formulation screening:It is also used to screen drug formulations to ensure that the final product is uniform and free of particles that are too large or too small.

5.Component separation:A sieve can separate different components in a drug mixture, which is necessary to meet specific formulation requirements.

Features of vibro sifter in the pharmaceutical industry

Different models of vibro sifter filter and sieve the output of pharmaceutical raw materials are also different. The larger the model, the greater the screening output. Generally speaking, the screening output of vibro sifter can range from 50kg/h to 2000kg/h.

Due to the different screening purpose and screen mesh size, the output of screening will also vary. For example, pellets and Chinese herbal medicines are generally used for simple removal of impurities due to the large mesh size of the sieve, and the sieving output and sieving efficiency will be higher than other powdery graded pharmaceutical raw materials.