Direct discharge sifter

Yield: 3-30 tons/hour

Screen surface diameter: 600-1470mm

Advantageous application: powder material removal of impurities

Filter Sieve

Output: 400-1200kg/h

Screen surface diameter: 450mm

Advantageous application: solid-liquid separation of liquid materials

Food Grade Vibro Sifter

Output: 100-3300kg/h

Screen surface diameter: 400-1800mm

Advantageous application: granular material separation and size determination of particles

It is a small filter equipment used to remove impurities from liquids. The liquid outlet can be designed with a valve, which can be applied to the filtration of food and beverages such as fruit juice, cold pressed oil, and milk.

The most basic form of Food Grade Vibro Sifter can handle granules, powders and liquids, and the machine form can be designed according to the material conditions.

It is often used at the front end of powder food production lines such as flour or cocoa powder, as a "quality inspector" to intercept impurities such as large particles or stones in food powder, with a large flow rate and a high pass rate.

Here, I divide the food into three categories: granule, powder and liquid, please choose according to your actual usage.

granular food

Examples: Nuts, corn, seeds, peanuts, coffee beans, and similar foods

Purpose of use: to remove sundries (stones, dust, shells, broken nuts, etc.) in the fruit, and to classify the fruit according to the particle size, which is convenient for processing or final packaging.

Selection of sieve: The pore size of the sieve for granular food is usually measured in cm, and take the appropriate value according to the size of your fruits and sundries.

Results of use: It can remove about 98% of impurities in food particles, and the grade separation effect on fruits can reach 95% and above, and the output is 100-3300kg/h.

Use effect display:

Get details and ask for a quote

Powdered food

Examples: Spice powder, flour, coffee powder, potato starch, milk powder and similar foods

Purpose of use: To remove uncompletely ground raw material particles and possible thread ends, stones or powder agglomerates in food powder.

Results of use: Remove 95%-98% of unqualified particles or impurities in the powder, making the food powder more fine, loose and uniform.

Sieve selection: The sieve aperture of powder food is measured in mm or mesh, the common flour mesh is 80-140 mesh, and the spice mesh is 80-100 mesh.

Special note: If your food powder is oily or highly adhesive (such as spice powder), don't worry, the fully polished Food Grade Vibro Sifter is smooth and not easy to adhere, and the machine's own cleaning device can avoid clogging.

Use effect display:

Get details and ask for a quote

Liquid food

Examples: fruit juice, milk, soy milk, cold-pressed oil, and similar foods

Purpose of use: To remove fibers, sediment or husk fragments and even fabrics that may exist in the liquid.

Results of use: Remove nearly 98% of solid impurities in the liquid, making the final food liquid more silky and delicate, and prolonging the storage time is not easy to degrade and deteriorate.

Selection of sieve mesh: choose about 50 mesh for viscous food liquid, and choose about 100 mesh for thin liquid.

Special note: The Food Grade Vibro Sifter sieve box is seamlessly welded, and a silicone sealing ring is added between the sieve frames for sealing. You can choose a waterproof and explosion-proof motor, so you don't have to worry about liquid leakage.

Use effect display:

Get details and ask for a quote

1. The mesh size of the sieve is 2-500 mesh (0.028mm, the mesh number of fine bread flour is about 140 mesh [0.106mm]), which can meet the separation and size determination of particles of almost all food materials.

2. The inside and outside are meticulously polished, the machine is smooth without dead corners and burrs, no food is hidden, and it is easy to clean;

3. Use the silicone sealing ring for food, which is tightly sealed and does not cause waste in the screening process;

4. The silica gel net-clearing pinball for food can ensure that the food can pass through the net quickly, and the food residue attached to the screen can be removed in time;

5. The upper cover and the flange ring inlet can be added to connect the crushing equipment or the feeding equipment; the 360-degree rotatable design of the discharge port can be adjusted according to the conditions of the production site.

There are many types of food. Generally speaking, it can be divided into powder, granular block and liquid food. In the process of food processing or final packaging, it is often necessary to pass sieving and filtration to ensure that the product can be processed smoothly or has a better qualityand taste, Food Grade Vibro Sifter can meet almost any food screening, impurity removal or filtering needs.

Basic Information of Food Grade Vibro Sifter

Material: 304/316L stainless steel

Number of layers: 1-5 layers can divide materials into 2-6 levels

Net cleaning: Silicone bouncing ball net cleaning device

Output: 100-3300kg/h (standard model)

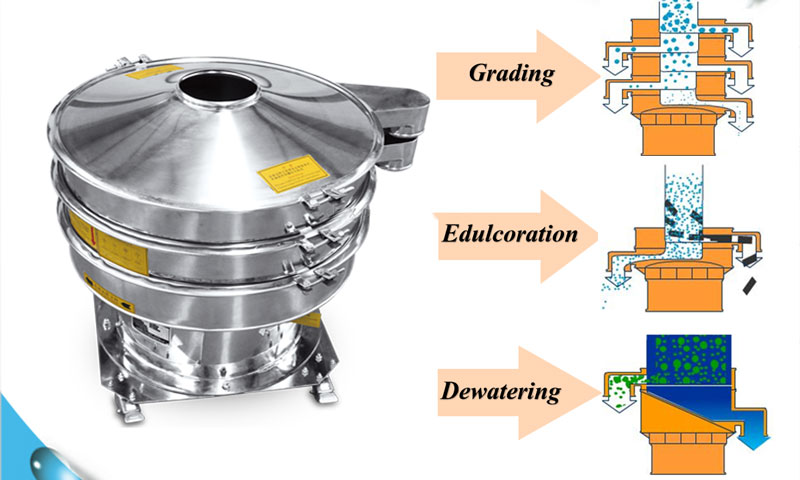

Uses: Single-layer filtration for impurity removal, multi-layer for grading

Mesh: 2-500 mesh (0.025mm-12.7mm)

Customer 1: The material is food additive powder, the material itself is about 100 mesh, the specific gravity of the material is 0.29, the screening accuracy is 40 mesh, and the processing capacity is 1000KG/h. Food Grade Vibro Sifter is required.

Solution: Install an ultrasonic deblinding system

Applicable conditions: suitable for fine powder materials with fine materials, light specific gravity and large output requirements.

Customer 2: Sieve seeds, 200 kg per hour, need a small model Food Grade Vibro Sifter to remove impurities, don't know the size of the mesh, use it yourself

Solution: Single Layer Small Model Food Grade Vibro Sifter

Applicable situation: home use, low cost, small space occupation

Customer 3: Sieve pepper granules for personal use. Choose a 1-meter rotary vibrating sieve. Choose 20 mesh, 30 mesh, or 60 mesh for the screen mesh. The material has good fluidity and 100 kg per hour. 50% of the above 20 mesh, and 30% of the 60 mesh or less

Solution: Adjust the diameter of the discharge port proportionally

Applicable conditions: suitable for large differences in the proportion of different fineness in the material, so that the output is smoother

| Application of food grade vibro sifter in food aindustry | |||||

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200 IT |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 IT |

| Salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏ |

| Orange juice | 1 | 80/100 | DH-1000-1S | Wet | 2200㎏ |

Food Grade Vibro Sifter for use in food processing plants

Food Grade Vibro Sifter Sieve Corn Kernels

Food Grade Vibro Sifter Sifted Cinnamon Powder

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Food Grade Vibro Sifter consists of dust cover, material inlet, material outlet, beam ring, stainless steel screen, counterweight, upper weight, vibration body, vibration motor, spring, base and other parts.

Dust-proof cover: prevent the material from spreading outward, and also protect the external dust from entering, thereby polluting the screened material.

Brace ring: used to fix the screen frame part in the middle of the screen body.

Upper heavy hammer, lower heavy hammer: Changing the phase angle of the upper and lower heavy hammers of the vibrating motor motor can change the trajectory and residence time of materials on the screen.

Spring: Vibration and sound insulation.

Frame: supporting stainless steel rotary vibrating screen.

1. Ultrasonic system: finer screening to prevent mesh blockage

2. Increase the feed inlet: prevent the liquid from splashing

3. Gate type: extend the time of food screening

4. Mobile: easy to move, suitable for frequent changes in screening locations

5. Feeding silo type: The silo is designed with a butterfly valve, which can control the feeding flow and is more convenient for feeding.

6. The height of the bottom barrel: it is convenient to combine with the production line and cooperate with the feeding equipment