Vibro sifter applied to juice processing

Friday February-28 2025 10:55:00

Vibro sifter used in juice processing workflow

The production and processing of fruit juice generally needs to go through the process of picking → sorting → cleaning → crushing and peeling → juicing → coarse filtration → blending → filtration → homogenization → degassing → sterilization → filling and sealing → sterilization → cooling inspection → packaging of finished products , Food vibro sifter is mainly used in the coarse filtration and filtration stages in fruit juice processing to separate impurities such as fiber, pulp, seeds and other impurities remaining in the juice from the juice to ensure the taste and quality of the juice.

How to classify a vibro sifter applied to juice processing?

There are many kinds of vibrating screens used in the field of juice processing, including circular vibrating screens, 450 filter screens, high-frequency screens, etc. The biggest difference between the 450 filter screen and the circular vibrating screen is that the rotating vibrating screen can do 5 layers, while the filter screen can only do 1 layer with an outlet, and the one-time feeding amount does not exceed 5 kilograms. The most important thing is that this equipment is suitable for the objects on the screen. There is less material, so it is suitable for juice slurry. If there is little residue, you can use the 450 type filter screen. The circular vibrating screen can be divided into several stages, up to 5 layers. Each layer has an outlet, which can be operated continuously and has manual cleaning. However, it is discharged directly from the outlet. It is suitable for screening and filtering of particles, powders, mucus and other materials. The high-frequency screen increases the vibration frequency. When the vibrating screen is subjected to high-frequency vibration, it can filter very viscous juice and achieve good filtration effects.

The food vibro sifter for juice removal is made of stainless steel and can be divided into two types: vibro sifter and 450 filter sieve.

The former vibro sifter is suitable for large-volume fruit juice production lines, and is usually used with large juicers, vacuum feeders and other equipment to form an automated juice production line.

The latter 450 filter sieves are mostly produced in small quantities or for household use. The machine is compact and takes up little space. The total weight of the machine does not exceed 50kg, which is convenient for storage when the machine is idle.

The design of food vibro sifter for impurity removal and filtration of fruit juice usually increases the upper feed port in order to avoid pollution and waste caused by juice splashing, and uses a waterproof motor to ensure that no production accidents occur during the juice filtration process.

How does a vibrating screen work?

Vibro sifter applied to juice processing is a new high precision fine powder screening machine. It uses vertical vibration motor as excitation source. This motor is equipped on both sides with an eccentric hammer which functions to transfer the rotation movement of motor to horizontal, vertical and inclined motions,and then transforms the motions to screen surface for sifting. The vibro sifter is widely applied in mediccal, food ,and other industries.

What are the advantages of vibro sifter applied to juice processing?

1. Good sealing performance. No leakage is the foundation of liquid filtration, and the food vibro sifter for juice filtration is sealed with a food-grade silicone seal to ensure no leakage.

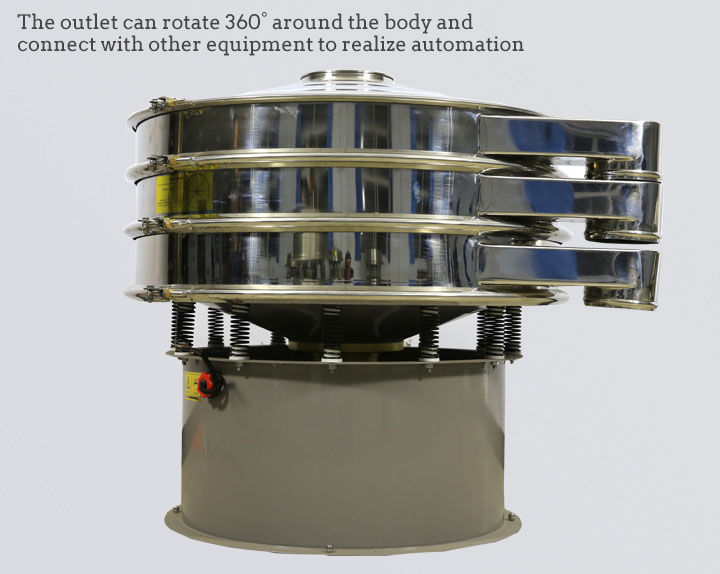

2. Automatic nesting. The fruit juice filter food vibro sifter is a single-layer design. Both the upper and lower layers have outlets. The upper layer can automatically discharge pomace, and the lower layer can automatically discharge juice. The outlet can rotate 360° around the body and connect with other equipment to realize automation. deal with.

3. 500-mesh sieve is equipped with net-cleaning pinballs. The sieve as fine as 500 mesh can filter most of the impurities in the juice, making the filtered juice more delicate. At the same time, for the characteristics of sugar in the juice and easy adhesion of wet impurities, the silica gel cleaning pinball can easily solve it.

Classic Case:

1. Fruit and vegetable juice: The apple juice and peach juice we drink are all blended with the original fruits and vegetables. The actual sieving of the original fruits and vegetables without water is only 40-60 meshes.

2. Fresh jujube juice: Usually, the red jujube juice we drink is made of chemical products. Fresh jujube juice is green in color and has a higher viscosity. There are more jujube meat. Screening purpose: It is necessary to remove part of the jujube meat to affect the taste. Mesh: 40 mesh.

3. Coconut juice: The milky white coconut juice we usually drink is filtered by a sieving machine and then processed and packaged. The purpose of sieving: It is necessary to remove the fine fibers in the coconut juice so as not to affect the taste. Mesh: 80 mesh.