Standard Test Sieve perforated plate screen

Monday February-24 2025 16:35:34

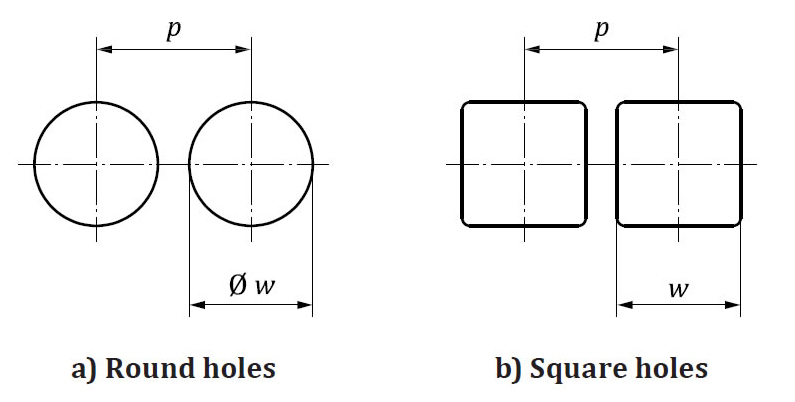

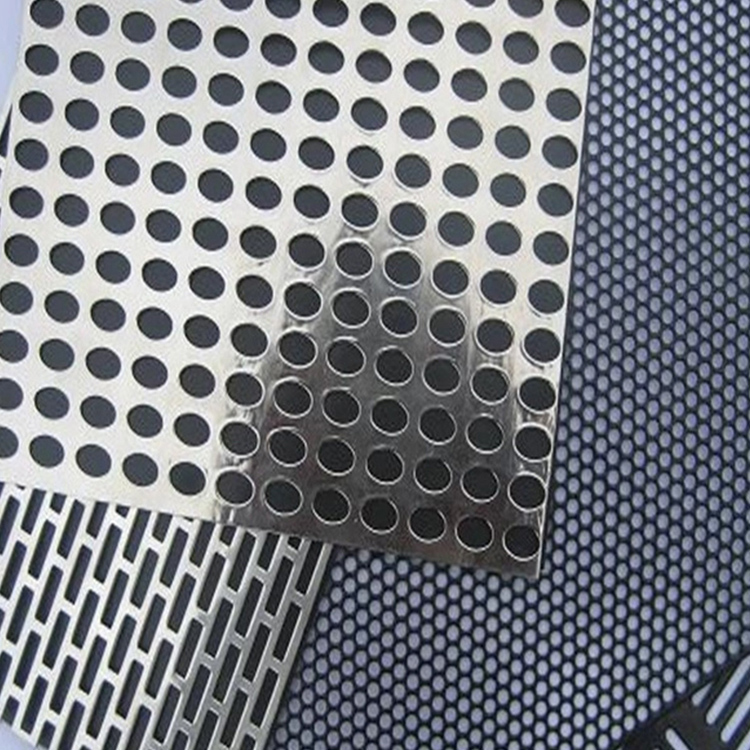

The Standard Test Sieve perforated plate screen is used to handle the analysis of samples with large particles or irregular blocks. The conventional hole types are round, square and rectangular, and various irregular shapes such as trapezoid and diamond can be customized.

Standard test sieves are made of either woven wire mesh or precision slotted metal perforated mesh. Both types of sieves have precise holes for profiling and analysis. The basic mesh of perforated plate sieves is punched metal sheet, made of aluminum, stainless steel, galvanized steel, etc. They are mainly used for screening and filtering granular and powdered materials in industries such as food, chemical, pharmaceutical, laboratory, construction, abrasive, metallurgy, etc.

Square hole sieves range in size from 125mm to 4mm and round hole sieves range in size from 125mm to 1mm.

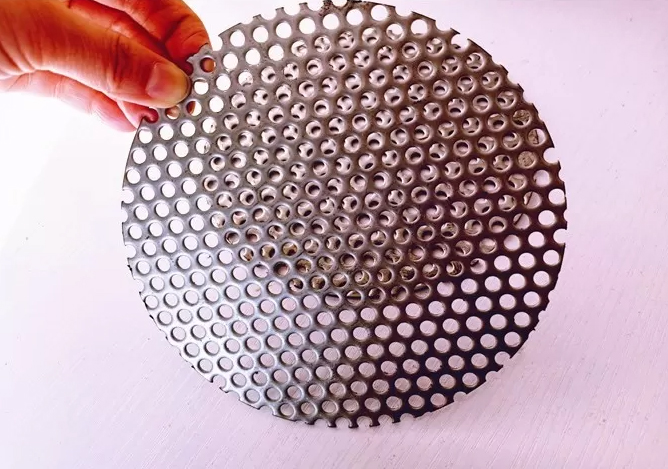

Regular styles are available in stainless steel and brass (200mm, 300mm diameter) and can be customized. In line with ISO international standards.

Product advantages:

1. The opening of mechanical punching is uniform and the opening rate is high;

2. The mesh is consistent, the edge is smooth, and the sample is not damaged;

3. The mesh surface is flat, and the sample can flow freely;

4. The edge of the screen frame is curled for safe operation;

5. Precise framework with consistent nestability.

Product data information:

Punching screen shape: square or round (can be customized)

Diameter: conventional 100, 200, 300mm (can be customized)

Diameter: 125 - 1mm round hole, 125 - 4mm square hole

Material: Stainless Steel / Brass / Plated Steel

Perforated mesh machine: The machine punches holes in metal plates. The punched mesh has different shapes. By changing the mold or punching die, it can meet the different needs of customers.

Function: particle size analysis, testing, measurement, and classification of granular materials

Applicable industries: coal, abrasives, building materials, chemicals, metallurgy and other industries.

Applicable materials for screening: coal, coke, soil, sand, etc.

Features: easy to use, wear-resistant, heat-resistant

What is a perforated plate screen?

Perforated plate screen is a test sieve that consists of a sheet of metal (galvanized or stainless steel) with multiple holes cut into it to screen the particles. The holes are laser cut for accuracy and can be round or square in shape.

Standard testStandard test sieve perforated plate sieve classification

Dahan Machinery's standard test sieve series includes: perforated plate test screen, standard test sieve with a diameter of 200 mm and a depth of 25 mm, various stainless steel wire mesh sieves, 75 micron test sieves, etc.

300mm standard test sieve perforated plate screen

300mm standard test sieve perforated plate screen is produced according to ISO3310-2:1990 standard, the sieve hole size ranges from 3.35mm to 0.038mm, the sieve frame and sieve cover are made of stainless steel, and the sieve mesh is made of brass, bronze, stainless steel, copper and other materials.

75mm standard test sieve perforated plate screen

75mm standard test sieve perforated plate screen aperture ranges from 500 microns to 5 microns, with an error of +2 microns, in line with ISO3310-3:1990 standard. The sieve is made of electroformed material, and its frame and cover are made of high-quality stainless steel. It is mainly used for precise classification of fine particle materials, and is widely used in metallurgy, abrasives, construction and other industries and scientific research laboratories. Other special apertures can be customized.

What are perforated plate standard test sieves made of?

Standard Test Sieve perforated plate screen is composed of a mesh frame and a screen. The mesh frame is made of stainless steel, which is non-magnetic and polished. The screen is divided into round or square hole punching plates, which will not deform after long-term use. The screen and the frame are fixed by welding and can withstand high temperatures of 300 degrees. The screen meets ISO3310, ASTM, BSI, DIN, and JIS standards.

What is the aperture size of the Standard Test Sieve perforated plate screen?

| Plate thicknesses | |||

| Dimensions in millimetres | |||

| Nominal sizes of holesw | Plate thickness | ||

| Permissible range of choice | Preferred thickness | ||

| Max. | Min | ||

| 125 to 50 | 3 | 3.5 | 2 |

| 45 to 16 | 2 | 2.5 | 1.5 |

| 14 to 8 | 1.5 | 2 | 1 |

| 7.1 to 1.7 | 1 | 1.5 | 0.8 |

| 1.6 to 1.0 | 0.6 | 1 | 0.5 |

Perforated metal sieves with round holes, from 1 mm to 125 mm, and perforated metal sieves with square holes, from 4 mm to 125 mm. The round and square holes in the perforated metal shall be arranged in a straight line or staggered. Sieves with a hole diameter of 4 mm and above shall have a non-porous edge. Partial holes are not permitted. The non-porous edge is affected by the hole diameter, spacing and manufacturing method, resulting in different edge widths.