Standard Test Sieve metal braided wire mesh

Friday February-21 2025 17:27:18

Standard test sieve metal braided wire mesh is the core component of the test sieve, which is mainly used for particle size analysis and screening of granular materials. It is woven from metal wires, usually stainless steel wires, copper wires, and other metal materials if the sample is special. It has the characteristics of high precision, wear resistance, and corrosion resistance, and is widely used in quality control and scientific research experiments in the pharmaceutical, chemical, food, metallurgical and other industries.

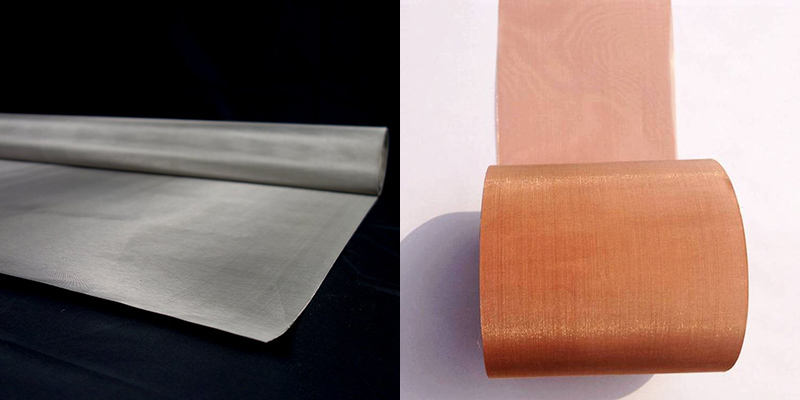

Metal braided wire mesh is woven from metal wire, usually stainless steel wire, copper wire can also be used, if the sample is special, other metal materials can also be selected.

What type of mesh is used in Standard test sieve metal braided wire meshes?

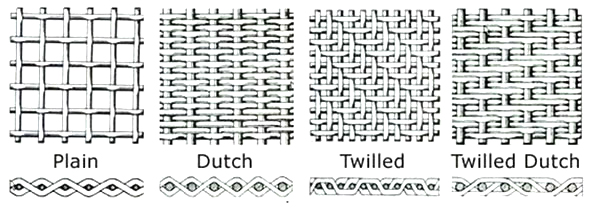

The mesh number of standard test sieve metal braided wire mesh is 2 mesh-635 mesh. The main weaving methods include plain weave, twill weave, Dutch weave, etc. It is acid-resistant, alkali-resistant, heat-resistant, and wear-resistant. The main material is SS304, 304L, 316, 316L stainless steel wire. The standard roll width of stainless steel wire mesh is 2'' to 8'', and the standard roll length of stainless steel wire mesh is 50'' to 100". We can also provide other specifications of stainless steel wire mesh, wrapped in moisture-proof paper and packed in wooden boxes. Stainless steel mesh is widely used in chemical, environmental protection, mining, aerospace, papermaking, electronics, metallurgy, food, pharmaceutical and other industries.

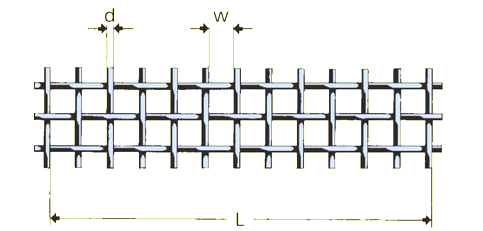

The diameter of metal braided wire can be selected from 10 mesh to 500 mesh, and the wire diameter varies according to the size of the mesh, and strictly follows the ISO9002 quality standard.

Metal woven wire mesh has plain weave, twill weave, plain Dutch weave, twill Dutch weave, reverse Dutch weave and other processes.

Main features of standard test sieve metal braided wire mesh

1. The mesh surface is smooth and smooth, and the sample flows freely without affecting the sieving;

2. Acid and alkali corrosion resistance, no rust, no contamination of samples;

3. The temperature resistance reaches 326℃, which can handle high temperature and low temperature materials;

4. The mesh is uniform and the aperture is accurate to ensure the accuracy of analysis;

5, a variety of specifications, accept customization.

Product Description of Standard test sieve metal braided wire mesh

Product Category: Metal Woven Wire Mesh

Aperture: 10-500 mesh, can be customized

Wire diameter: according to the hole diameter, can be customized

Material: 304/316L stainless steel, copper, etc.

Production process: cold drawn wire / precision welding

Application areas: food/mining/chemical/pharmaceutical/petroleum/paint, etc.

Standard test sieve metal braided wire meshes are available in a variety of configurations for use in a number of different particle size measurement applications. Some meet specific requirements of specific SATM or ISO specifications. Most Standard test sieve metal braided wire meshes are stacked or nested with other Standard Test Sieve Woven Wire Meshes of similar construction to achieve efficient, continuous separation. Traditional test sieves have a stainless steel or brass round metal frame with a mesh made of woven stainless steel or brass wire.

| Standard sizes of Standard test sieve metal braided wire mesh | |

| Material | 304 316 316L stainless steel, red copper,brass etc |

| Diameter | 10-600mm, available customized |

| Micron | 1-2000 micron, according to customer's requires |

| Hole shape | Round, square and rectangular |

| Height | 3.5-10cm, available customized |

| Application | Standard test sieve metal braided wire mesh is suitable for accurate screening and analysis, testing, measurement and classification of powdered materials in laboratories, hospitals, pharmaceuticals, food, metallurgy, construction and other departments. |

What is the standard test sieve metal braided wire mesh?

ANSI: The AWCI 01 standard was developed by the American National Standards Institute and covers wire mesh manufactured in the United States. This standard establishes the use of wire mesh in industrial and screening environments.

ASTM E11: The American Society for Testing and Materials (ASTM) developed the E11 standard, which outlines the manufacturing process for test screens. The E11 guidelines address screen cloth opening size, diameter of the individual wires in the screen cloth, screen frame height, screen frame diameter, and screen cloth installation.

ASTM E2016: The American Society for Testing and Materials developed the ASTM E2016 standard, which specifies the use of industrial wire mesh when screening materials to measure particle size. This includes various wire mesh screens, methods, and other various screening media used to separate particles based on size.

ASTM E437 is an industrial wire mesh standard that specifically regulates square mesh. This standard is designed to cover basic square mesh applications. Four different grades of square mesh are established based on mesh count and wire diameter. The overall mesh tolerances shown in the standard are based on the aperture width.

What sizes of Standard test sieve metal braided wire mesh are available?

| Number |

Mesh (mm) |

Number |

Mesh (mm) |

Number |

Mesh (mm) |

Number |

Mesh (mm) |

| 2 | 13 | 26 | 0.71 | 90 | 0.16 | 260 | 0.06 |

| 3 | 6.5 | 28 | 0.63 | 100 | 0.154 | 280 | 0.055 |

| 4 | 5 | 30 | 0.6 | 110 | 0.14 | 300 | 0.054 |

| 5 | 4 | 32 | 0.55 | 115 | 0.13 | 320 | 0.048 |

| 6 | 3.2 | 36 | 0.5 | 120 | 0.125 | 325 | 0.045 |

| 7 | 2.8 | 40 | 0.45 | 130 | 0.111 | 350 | 0.041 |

| 8 | 2.5 | 45 | 0.4 | 140 | 0.105 | 360 | 0.4 |

| 9 | 2.2 | 50 | 0.355 | 150 | 0.1 | 400 | 0.0385 |

| 10 | 2 | 55 | 0.315 | 160 | 0.098 | 500 | 0.03 |

| 12 | 1.6 | 60 | 0.3 | 180 | 0.09 | ||

| 14 | 1.43 | 65 | 0.25 | 190 | 0.08 | ||

| 16 | 1.25 | 70 | 0.22 | 200 | 0.075 | ||

| 18 | 1 | 75 | 0.2 | 220 | 0.07 | ||

| 20 | 0.9 | 80 | 0.18 | 240 | 0.065 | ||

| 24 | 0.8 | 85 | 0.17 | 250 | 0.063 | ||

| Standard test sieve metal braided wire mesh specifications, if you need special specifications, you can contact online customer service consultation. | |||||||

FAQs for Standard test sieve metal braided wire mesh

1. Are you a factory/manufacturer or trader?

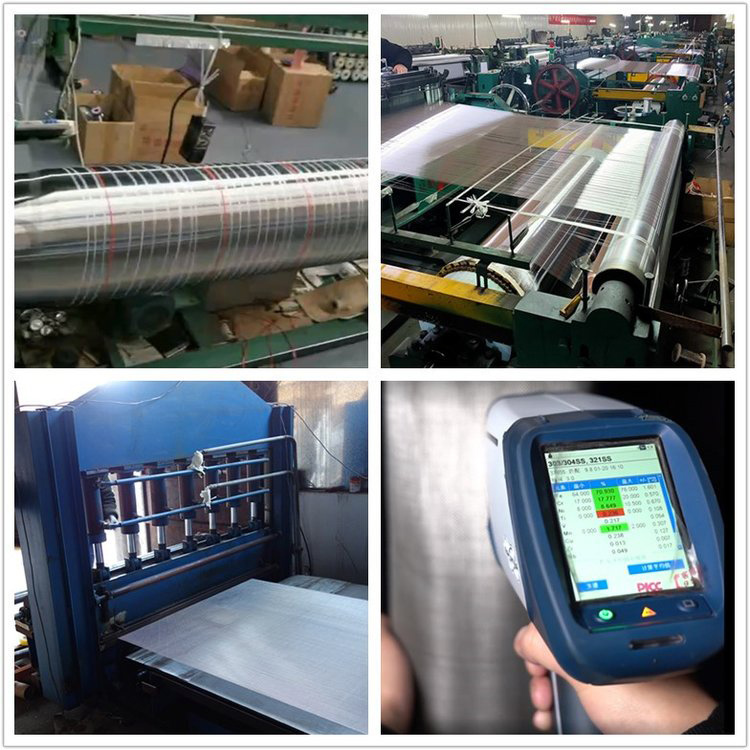

We are a direct sales factory with production lines and workers. Everything is flexible, no need to worry about extra costs from middlemen or traders.

2. Can I get free samples?

Yes, you can get samples for free, and special specifications can be customized according to your requirements if needed.

3. What is your minimum order quantity?

Actually there is no MOQ for our products. But usually we will recommend a suitable quantity based on a favorable price that is easily acceptable (low shipping and production cost).

4. How long is the delivery time after payment?

Usually the delivery time is 7-15 days (in stock), 30 days for customized products.

Why choose us?

Professional and experienced factory (15 years)

Professional quality control and design team for your products

Fast delivery and good quality

Made in China, certified Chinese supplier and manufacturer

Multiple transportation methods are available for you to choose (train, sea, air) to meet your requirements and the size and volume of your goods.