Screen mesh number and particle size comparison table and related knowledge

Saturday March-08 2025 14:25:58

The particle size of a material is usually expressed in microns or mesh. Here you will find a useful particle size conversion table showing the micron to grid conversion for a quick comparison of particle size between these two units. The chart also allows you to compare screen names and screen openings in inches, millimeters, or microns.

What is Mesh Size?

Mesh size is expressed by the number of mesh holes per square centimeter in Chinese specifications, and is expressed by the number of mesh holes per inch internationally, and is also expressed by the size of each mesh hole (mm). The larger the mesh size, the finer the material particle size and the larger the material particle size. The sieving particle size is the mesh size that the particles can pass through the screen, and the number of meshes in 1 inch (25.4mm) length is called mesh size.

The specifications of standard sieves vary from country to country. The commonly used Taylor system uses the number of holes per inch as the sieve number, which is called mesh. For example, a 100 mesh sieve means there are 100 sieves per inch of screen.

| Particle Size Conversion Chart | |||||

| B.S.S MESH | A.S.T.M. MESH | TYLER MESH | I.S.S MESH | MICRON | IN MM |

| 4 | 5 | 5 | — | 4000 | 4.00 |

| 6 | 7 | 7 | 280 | 2812 | 2.81 |

| 8 | 10 | 9 | 200 | 2057 | 2.05 |

| 10 | 12 | 10 | 170 | 1680 | 1.68 |

| 12 | 14 | 12 | 150 | 1405 | 1.40 |

| 14 | 16 | 14 | 120 | 1240 | 1.20 |

| 16 | 18 | 16 | 100 | 1003 | 1.00 |

| 18 | 20 | 20 | 85 | 850 | 0.85 |

| 22 | 25 | 24 | 70 | 710 | 0.71 |

| 30 | 35 | 32 | 50 | 500 | 0.50 |

| 36 | 40 | 35 | 40 | 420 | 0.42 |

| 44 | 45 | 42 | 35 | 355 | 0.35 |

| 52 | 50 | 48 | 30 | 300 | 0.30 |

| 60 | 60 | 60 | 25 | 250 | 0.25 |

| 72 | 70 | 65 | 20 | 210 | 0.21 |

| 85 | 80 | 80 | 18 | 180 | 0.18 |

| 100 | 100 | 100 | 15 | 150 | 0.15 |

| 120 | 120 | 115 | 12 | 125 | 0.12 |

| 150 | 140 | 150 | 10 | 105 | 0.10 |

| 170 | 170 | 170 | 9 | 90 | 0.09 |

| 200 | 200 | 200 | 8 | 75 | 0.075 |

| 240 | 230 | 250 | 6 | 63 | 0.063 |

| 300 | 270 | 270 | 5 | 53 | 0.053 |

| 350 | 325 | 325 | 4 | 45 | 0.045 |

| 400 | 400 | 400 | — | 37 | 0.037 |

| 500 | 500 | 500 | — | 25 | 0.025 |

| 625 | 625 | 625 | — | 20 | 0.020 |

| British Standard Sieve | American Standard Sieve | Taylor Standard Sieve | International standard sieve | Micron control | Mm control |

It can be seen from this definition that the size of the mesh determines the size of the sieve mesh. The size of the sieve aperture determines the Dmax of the large particles of the sieved powder. Therefore, we can see that the 400 mesh polishing powder may be very fine, such as only 1-2 microns, and it is entirely possible that it is 10 microns or 20 microns. Because the pore size of the screen is about 38 microns. The D50 of our 400 mesh polishing powder is 20 microns.

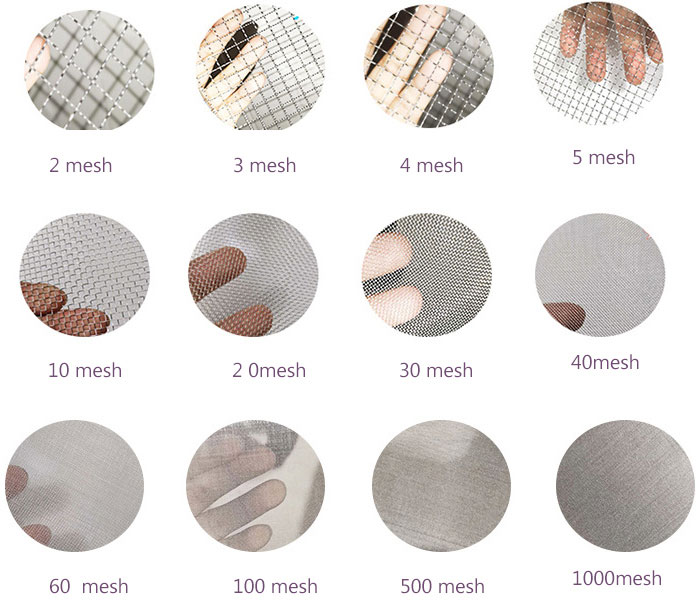

Mesh size comparison

What is a micron?

Microns are the length measure most commonly used to describe the size of tiny particles. The word micron is actually a common shorthand for micron (US spelling) or micron (international spelling). The official symbol for a micrometer or micrometer is μm, sometimes abbreviated to um. A micron is defined as one millionth of a meter, slightly larger than one thousandth of an inch.

Mesh and Micron Sizes Chart

| Mesh (mesh) | Micrometer (μm) | Mesh (mesh) | Micrometer (μm) | Mesh (mesh) | Micrometer (μm) |

| 2 | 8000 | 42 | 355 | 180 | 80 |

| 3 | 6700 | 45 | 325 | 200 | 75 |

| 4 | 4750 | 48 | 300 | 230 | 62 |

| 5 | 4000 | 50 | 270 | 240 | 61 |

| 6 | 3350 | 60 | 250 | 250 | 58 |

| 7 | 2800 | 65 | 230 | 270 | 53 |

| 8 | 2360 | 70 | 212 | 300 | 48 |

| 10 | 1700 | 80 | 180 | 325 | 45 |

| 12 | 1400 | 90 | 160 | 400 | 38 |

| 14 | 1180 | 100 | 150 | 500 | 25 |

| 16 | 1000 | 115 | 125 | 600 | 23 |

| 18 | 880 | 120 | 120 | 800 | 18 |

| 20 | 830 | 125 | 115 | 1000 | 13 |

| 24 | 700 | 130 | 113 | 1340 | 10 |

| 28 | 600 | 140 | 109 | 2000 | 6.5 |

| 30 | 550 | 150 | 106 | 5000 | 2.6 |

| 32 | 500 | 160 | 96 | 8000 | 1.6 |

| 35 | 425 | 170 | 90 | 10000 | 1.3 |

| 40 | 380 | 175 | 86 |

Instead of converting the grid to your official formula, I tried to develop a conversion formula that roughly correctly converts the grid to microns.

Mesh*Micron=14900 (approximately)

Micron=14900/mesh and mesh=14900/micron

It has some errors, but it's still useful to get an approximation when converting between 50 and 400 meshes.

The conversion of grids and inches can be done by adapting the following formula:

Inch = 0.6/mesh

Mesh = 0.6/inch

Standard mesh number:

1. Mesh refers to the number of holes on the screen per square inch

50 mesh means that there are 50 perforations per square inch, and 500 mesh means 500. The higher the mesh, the more perforations. In addition to the perforations of the sieve, it is also used to represent the particle size of the particles that can pass through the sieve. The higher the mesh, the smaller the particle size. The standard sieve needs to be matched with a standard vibrating machine for accurate determination.

2. The particle size of the powder is called the particle size.

Due to the complexity of the particle shape, there are usually several expression methods such as sieving particle size, sedimentation particle size, equivalent volume particle size, and equivalent surface area particle size. The sieve size is the size of the sieve holes that the particles can pass through the sieve, expressed as the number of sieve holes in a 1 inch (25.4mm) wide sieve, so it is called the "mesh number". At present, there is no unified powder particle size technical standard at home and abroad, and each enterprise has its own definition and expression method of particle size index. In different countries and different industries, the screen specifications have different standards, so the meaning of "mesh" is also difficult to unify. At present, international comparisons use the calculated diameter of particles of equivalent volume to express the particle size. Expressed in μm or mm

Attachment: Conversion relationship: 1 μm = 1 micrometres (micrometers) = 0.001 millimetres (millimeters)

| Common mesh/aperture conversion Specification: 200*50mm | |||||

| Mesh size: mm | Standard mesh number: mesh | Mesh size: mm | Standard mesh number: mesh | Mesh size: mm | Standard mesh number: mesh |

| 4.75 | 4 | 0.106 | 140 | 0.710 | 25 |

| 3.35 | 6 | 0.0750 | 200 | 0.500 | 35 |

| 2.36 | 8 | 0.0530 | 270 | 0.355 | 45 |

| 1.70 | 12 | 0.040 | 363 | 0.250 | 60 |

| 1.18 | 16 | 0.0025 | 500 | 0.180 | 80 |

| 0.0850 | 20 | 4.00 | 5 | 0.125 | 120 |

| 0.600 | 30 | 2.80 | 7 | 0.090 | 170 |

| 0.425 | 40 | 2.00 | 10 | 0.0630 | 230 |

| 0.300 | 50 | 1.70 | 12 | 0.0450 | 325 |

| 0.212 | 70 | 1.00 | 18 | 0.0038 | 400 |

| 0.150 | 100 | 0.0750 | 200 | 0.0020 | 600 |

The empirical formula for the conversion between micron and mesh is as follows, the larger the mesh, the greater the error.

Sieve inner diameter (μm)≈14832.4/sieve mesh

The mesh size of the unit of measurement refers to the size of the raw material particles, which is generally expressed by the large length of the particles. The mesh is the size of the mesh size of the standard sieve. In the Taylor standard sieve, the so-called mesh is the number of sieve openings in a length of 2.54 cm (1 inch), and is referred to as the mesh for short.

Taylor standard sieve system: The division of the Taylor sieve system is based on the 200-mesh sieve size of 0.074mm, multiplied or divided by the main modulus root (1.141) to the nth power (n=1, 2, 3...) , You can get a coarser or finer sieve size of 200. If the n-th power of the fourth root of 2 (1.1892) is multiplied or divided by 0.074mm, a series of finer sieve sizes can be obtained.

The larger the mesh, the finer the particles. Similar to the magnification of the metallographic structure.

The plus or minus sign before the mesh indicates whether the mesh of the mesh can be missed. A negative number means that the mesh can pass through the mesh, that is, the particle size is smaller than the mesh size; while a positive number means that the mesh cannot pass the mesh, that is, the particle size is larger than the mesh size. For example, if the particles are -100 mesh to +200 mesh, it means that these particles can leak through the 100-mesh mesh but cannot leak through the 200-mesh mesh. When selecting particles of this mesh, the mesh number should be large ( 200) is placed under the small mesh (100) screen, and the particles left in the large mesh (200) screen are -100~200 mesh particles.

The number of meshes is the number of holes, which is the number of holes per square inch. The larger the mesh, the smaller the aperture. Generally speaking, the number of meshes × aperture (number of microns) = 15000. For example, the aperture of a 400 mesh screen is about 38 microns; the aperture of a 500 mesh screen is about 30 microns. Due to the problem of opening rate, that is, because of the difference in the thickness of the wire used in weaving the net, the standards of different countries are different. There are currently three types of American standards, British standards and Japanese standards. Among them, the United Kingdom and the United States are similar. , Japan is quite different. Our country uses the American standard, that is, it can be calculated with the formula given above.

It can be seen from this definition that the size of the mesh determines the size of the sieve mesh. The size of the sieve aperture determines the Dmax of the large particles of the sieved powder. Therefore, we can see that the polishing powder of 400 mesh is completely possible to be very fine, such as only 1-2 microns, and it is completely possible to be 10 microns or 20 microns. Because the pore size of the screen is about 38 microns. The D50 of our 400 mesh polishing powder is 20 microns. The attached picture shows the photo of this polishing powder. Note that the scale is 50 microns.

Therefore, it is not appropriate to use the mesh number to determine the particle size of the polishing powder. The correct way is to use the particle size (D10, median diameter D50, D90) to express the particle size, and use the mesh number to convert the larger particle size. If you have read the Japanese standard for abrasives, JIS, you will think it is very scientific. Each of their abrasives has the requirements of D3, D50, D97, and the data when using different principle particle size analyzers are different. The requirements are very strict. For example, D50 is 2 microns powder, D3 is approximately 0.9 microns, and D97 is 4 microns. What does that mean? In the powder that is claimed to be 2 microns, less than 0.9 microns cannot exceed 3%, and those greater than 4 microns cannot exceed 3%. This is very strict, and most of the polishing powders (including foreign ones) seen on the market cannot meet this requirement, especially the fine powder that exceeds the standard.

There is a reason why the mesh number is used to characterize the particle size of the polishing powder. The old polishing powder factory uses the process of dry ball milling and dry sieving, so the D50 of 300 mesh powder is about 9 microns, and the D50 of 500 mesh is about 2 microns. Everyone has been using it in this way, and can basically guide the production and use. However, with the emergence of new production processes and the demand for polishing with higher precision, this method should also be improved.

| Mesh | Aperture ﹙㎜﹚ | Mesh | Aperture ﹙㎜﹚ | Mesh | Aperture ﹙㎜﹚ | Mesh | Aperture ﹙㎜﹚ | ||

| 2 | 13 | 24 | 0.8 | 80 | 0.18 | 220 | 0.07 | ||

| 3 | 6.5 | 26 | 0.7 | 85 | 0.17 | 240 | 0.065 | ||

| 4 | 5 | 28 | 0.63 | 90 | 0.16 | 250 | 0.063 | ||

| 5 | 4 | 30 | 0.6 | 100 | 0.154 | 260 | 0.06 | ||

| 6 | 3.2 | 32 | 0.55 | 110 | 0.14 | 280 | 0.055 | ||

| 7 | 2.8 | 36 | 0.5 | 115 | 0.13 | 300 | 0.054 | ||

| 8 | 2.5 | 40 | 0.45 | 120 | 0.125 | 320 | 0.048 | ||

| 9 | 2.2 | 45 | 0.4 | 130 | 0.111 | 325 | 0.045 | ||

| 10 | 2.0 | 50 | 0.335 | 140 | 0.105 | 350 | 0.041 | ||

| 12 | 1.6 | 55 | 0.315 | 150 | 0.10 | 360 | 0.040 | ||

| 14 | 1.43 | 60 | 0.3 | 160 | 0.098 | 400 | 0.0385 | ||

| 16 | 1.25 | 65 | 0.25 | 180 | 0.09 | 500 | 0.030 | ||

| 18 | 1.0 | 70 | 0.22 | 190 | 0.080 | 600 | 0.025 | ||

| 20 | 0.9 | 75 | 0.2 | 200 | 0.075 | 800 | 0.020 | ||

| 1000 | 0.015 | 1250 | 0.010 | ||||||

| Test sieve specifications, if you need special specifications, please contact online customer service for consultation | |||||||||

Determine of mesh size of any screen

This is a very easy way to determine the mesh size of any sieve. Carefully mark the sieve 1 inch using permanent edits and graduations. The measurement should start at the center of the wire to make it more accurate, count the number of holes in this area, the number of holes in an inch becomes the grid. Example: If 60 holes are found within an inch, the sieve has a mesh size of 60.

Screen mesh manufacturer

Dahan Manufacturer specializes in producing test sieves of various specifications to meet different needs. If you are interested in our products or have any questions, please feel free to contact us. You can contact us via WhatsApp or email us.

My whatsapp: +86 15236742901

e-mail: sale@xxdahan.com

We will send you details and quotation

Our team is always here to provide you with detailed information and support, and we look forward to working with you!