Optional options for Ultrasonic Sifter

Tuesday February-25 2025 10:37:01

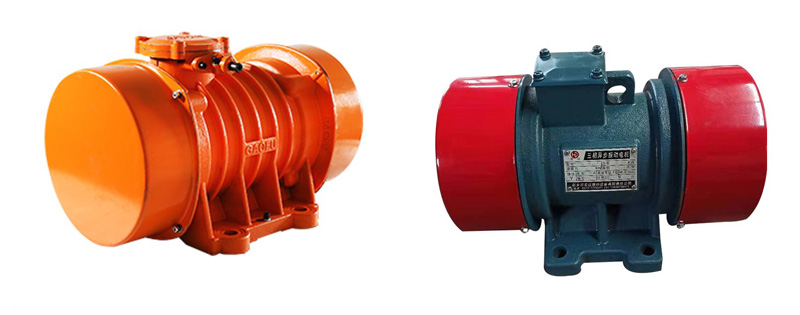

Motor

The conventional motor is a three-phase motor. If the material to be screened is special, it is easy to generate static electricity or even explode, then you can choose an explosion-proof motor with better sealing performance, which will not generate electrical sparks during operation to ensure the safety of screening and the working environment of production personnel security.

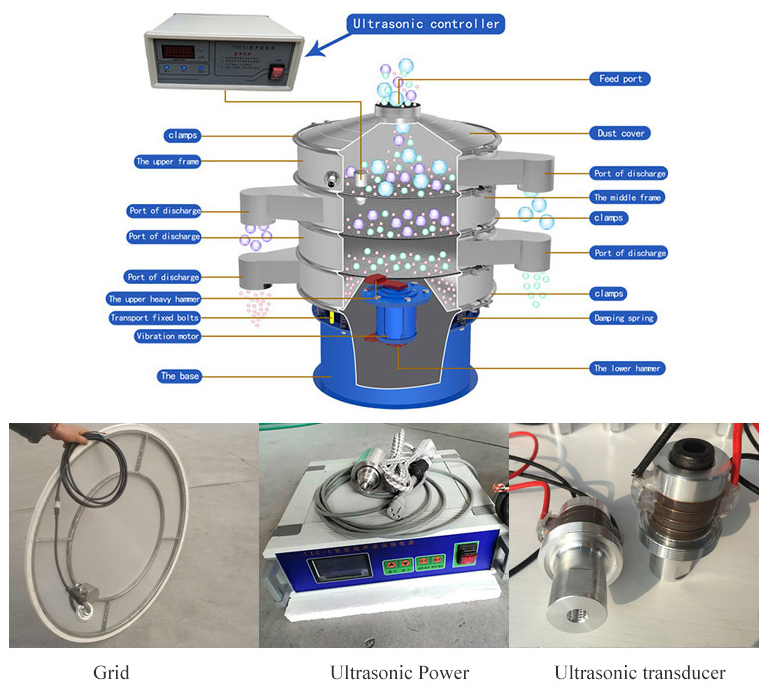

Ultrasonic transducer

Ultrasonic transducers are divided into built-in ultrasonic transducers and external ultrasonic transducers.

Built-in ultrasonic transducer: The ultrasonic transducer connector is placed in the middle of the ultrasonic screen mesh, and can directly contact the material when working. It is low-cost. The price of the built-in system on the market is half that of the external system.

External ultrasonic transducer: The ultrasonic transducer is installed on the outside of the mesh frame and extends to the edge of the mesh frame. Since it avoids direct contact with the material, it avoids material contamination, meets the hygiene standards of the food and pharmaceutical industries, and has a low failure rate, which improves production capacity.

The ultrasonic screening machine can use one generator to excite multiple ultrasonic transducers at the same time. Due to the change in frequency, even screening machines with different resonance characteristics can be excited at the same time.

①For larger screen frames, one generator can be used to excite multiple ultrasonic transducers to process single large or multiple waveguide rings. Ultrasonic sifter can be connected with a single ultrasound, or a single double ultrasound can be connected

②Even a single screen frame (such as a sifter with two or more screen plates) can be started simultaneously. Multiple series connection methods, more comprehensive coverage and more thorough screening

Support grid

According to the screen surface area of Ultrasonic Sifter, the choice of support grid is determined. For small screen surface, annular support grid can be selected, and for large screen surface area, concentric circular support grid can be selected. Compared with the annular mesh frame, the concentric circular mesh frame has a lateral support structure, which has a better support and leveling effect on the screen mesh and avoids damage to the large-area screen mesh.

Sieve Frame Ring

The standard Ultrasonic Sifter upper and lower sieve frame ring is two semi-circular metal rings fixed and tightened by screws, which play a role of stabilizing the sieve box.

You can choose to quickly attach and detach the beam ring, and you only need to open and close the movable buckle to complete the replacement of the screen mesh or to remove the screen frame, which is a faster and more time-saving design.

Ultrasonic transducer

Internal displacement transducer Ultrasonic Sifter: Screening of non-corrosive common powder materials, difficult to clean, high damage rate and low price;

External displacement transducer Ultrasonic Sifter: suitable for all powder material screening situations, not easy to damage, easy to clean, high price.

Sealing Ring

The rubber sealing ring is used in the screening of ordinary materials without special requirements for hygiene.

Silicone sealing ring is cleaner and hygienic, and it is food and medicine grade, non-toxic. When your screening products have strict hygiene requirements, choose silicone seals, and silicone seals are usually used with 304 or 316L Ultrasonic Sifter.

Available options display

Optional options for ultrasonic sifter include vibration motor, outer mesh ring and resonance ring, screen, mesh frame, ultrasonic transducer, sealing ring and other parts.

The transducer adopts a high-performance ultrasonic conversion device with a sealed structure to prevent the entry of fine powder; the ultrasonic grid frame consists of an outer grid frame and a resonant ring, and a variable number of waveguide rings can be inserted into the frame according to the size of the frame.