Introduction and product application of Tumbler Screen

Wednesday February-26 2025 11:02:00

Tumbler Screen imitates manual sieving. The material will be shaken and scattered on the screen and slightly thrown upwards and lows. Repeated in the sieve box layer by layer, it will be sieved according to the requirements. The sieving efficiency is generally 93%~95%.

Introduction of Tumbler Screen

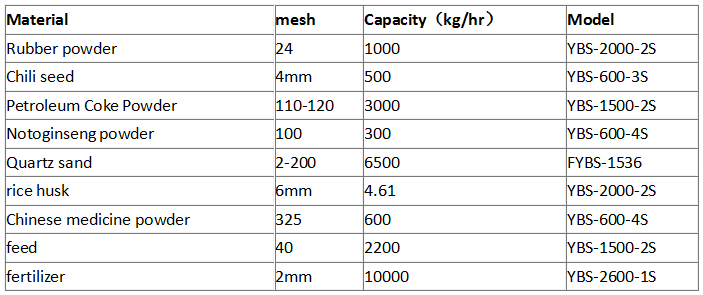

The output of Tumbler Screen is about 6~60t/h, and the output will vary according to different materials. It has obvious advantages in screening materials below 600 mesh.

What is a tumbler screen?

Through the special mechanical structure design, tumbler screen realizes the principle of imitating manual screening. It combines the two forms of horizontal swing and vertical upward throwing movement in manual screening action, and adds tangential throwing movement. Through the adjustment and good combination of the three forms of movement, the uniform distribution of materials on the screen surface and the spiral outward complex movement of three-dimensional space are achieved, effectively and efficiently The entire circumferential screen surface is used to improve the screening efficiency; in view of the difficulties in dry and wet screening of fine-grained materials, through reasonable adjustment of eccentricity, radial deflection angle and tangential deflection angle, predetermined multiple movement modes are achieved, which is suitable for effective screening of different materials in many industries; it can be used as a screening and grading screening of process systems; it is suitable for granular or powdery materials, the finest can reach micron level.

Features of tumbler screen

Screening efficiency up to 99%

No particle destruction in sensitive products

High screening quality results in higher revenues for graded products

Higher specific screen load as compared to vibration systems

Stable screen motion even under full load

Product specific mesh cleaning systems

Quick access to the screen inserts

Modular design permits various machine modifications

No vibration,low speed and longer service life

Noise less than 75dB, easy to maintain

Structure of tumbler screen

Application of tumbler screen

1、Food industry: sugar, spices, starch, soybeans, salt, instant potatoes, animal feed, powdered milk, cereals and grains, tobacco, teff, instant coffee granules, chocolate powder, soybean flour, broth concentrate, potato granules, sugar beets, ice cream, fruit juices, vegetable and pickle canneries, soybean oil.

2、Construction Industry: sand, glass beads, plaster, abrasives Grit/shot, borax.

3、Chemical Industry: fertilizer, rubber, polystyrene beads, paint, detergents, latex, catalyst, casein.

4、Recycle: animal blood, paper effluent, brewer yeast, sewage, manure, brewery waste, laundry waste, potato peelings and waste, tallow.

Tumbler Screen is very suitable for the separation and dedusting of dry, powdery and granular products, especially for multi-layer separation of high-yield and fine, light and difficult-to-screen products, widely used in food, medicine, chemical industry and high-performance materials (plastics ) and minerals for feed rates from 10 kg/h to 40 t/h.

Tumbler Screen motion is similar to simple manual sieving, combining sieving (circular motion) and hand sieving (parabolic motion), the sieving trajectory is a 3D ellipse, which can be used for the separation and dust removal of powdery and granular products, and the screening accuracy It can reach more than 95%, and the processing capacity is 3-5 times that of ordinary screening machines. It is especially suitable for fine, light and difficult materials with high feed rate (10kg/h-40t/h) and multi-layer separation (1-6 grades). Filtered products.