Gypsum for Powder Sieve Equipment

Wednesday February-19 2025 13:45:21

Product overview of gypsum for Powder Sieve Equipment

Gypsum for Powder Sieve Equipment plays an important role in the building materials industry. Gypsum powder is a commonly used building material and is widely used in gypsum boards, gypsum products, architectural coatings and other fields. In order to obtain high-quality gypsum powder, sieve equipment is widely used in the production process of gypsum powder.

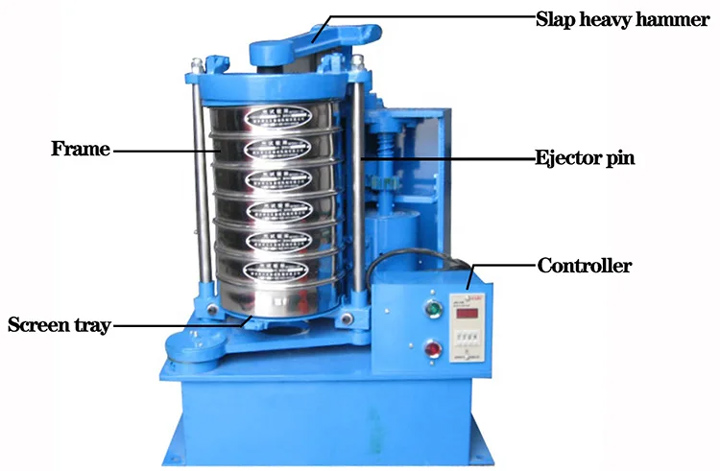

Gypsum for powder sieve equipment mainly grades and screens raw materials through the movement of vibrating screens. It consists of vibration motor, screen, screen box, etc. The gypsum powder enters the screen box through the feed port, and then driven by the vibration motor, the screen box starts to vibrate, so that the gypsum powder is screened on the screen. As needed, screens of different specifications can be set up to achieve screening of gypsum powder of different particle sizes.

The main function of Gypsum for powder sieve equipment is to remove impurities and large particle materials in gypsum powder to ensure the quality and uniformity of gypsum powder. The screened gypsum powder can be directly used in production to improve product quality and performance.

The microporous structure and thermal dehydration properties of gypsum powder and its products give it excellent sound insulation, heat insulation and fire resistance. It is a widely used industrial and building material that can be used as cement retarders, gypsum building products, model making, medical food additives, sulfuric acid production, paper fillers, paint fillers, etc.

| Material characteristics | Production capacity | Application materials | Features of delivery of gypsum powder complete production line |

| Mixture of powder and powder, powder and a small amount of liquid | 1500~30,000 tons/year | Applicable to various gypsum powders used in building materials, chemical industry, mold, food, casting and other industries | The production line consists of raw material storage system, batching system, liquid supply system, mixing system, finished product storage system, packaging system, suction system, steel structure system, control system, and adopts automated production |

What are the advantages of gypsum for powder sieve equipment

Efficient screening: The vibration force of the vibrating screen and the design of the screen enable the gypsum powder to pass quickly during the screening process, improving screening efficiency.

Precise screening: Screen mesh of different specifications can be selected according to needs to achieve precise screening of gypsum powder particle size and ensure product consistency.

Adjustability: The vibration force of the screening equipment and the angle of the screen can be adjusted to suit different screening requirements, providing flexibility and customizability.

Automated operation: Gypsum for powder sieve equipment can be automatically connected with other production equipment to realize automated production processes, improve production efficiency and reduce labor costs.

What is Gypsum for Powder Sieve Equipment used for?

Gypsum board production: Gypsum board is a commonly used decorative material in construction, and gypsum powder is one of the main raw materials of gypsum board. In the gypsum board production process, gypsum for powder sieve equipment is used to screen gypsum powder to remove impurities and large particle materials to ensure the quality and consistency of gypsum boards.

Gypsum product manufacturing: In addition to gypsum boards, gypsum is also widely used in the manufacture of other gypsum products, such as gypsum lines, gypsum sculptures, etc. In these manufacturing processes, gypsum for powder sieve equipment is used to screen and classify gypsum powder to obtain gypsum powder that meets the requirements and ensure the quality and appearance of the product.

Architectural coating production: Gypsum powder is also an important component of some architectural coatings. In the production process of architectural coatings, gypsum for powder sieve equipment is used to screen and classify gypsum powder to obtain fine gypsum powder to ensure the quality and coating effect of the coating.

Gypsum powder packaging: Gypsum for powder sieve equipment can also be used in the packaging process of gypsum powder. Before packaging, the gypsum powder needs to be screened to remove impurities and large particles to ensure the quality and uniformity of the packaged gypsum powder. The screened gypsum powder can be directly used for packaging, improving packaging efficiency and product quality.

Gypsum for Powder Sieve Equipment production line

Raw materials——→unpacking (small bags, ton bags)——→raw materials pre-processing (crushing/screening)——→raw materials storage——→batch system (incremental method, loss-in-weight method)——→mixing system——→finished product processing (crushing/screening)——→finished product storage——→packaging system——→final product.

Technical parameters of gypsum for Powder Sieve Equipment

| System components | functions | optional equipment | comments |

| Raw material handling system | unpacking, feeding | small bag feeding station, ton bag feeding station, ton bag and small bag integrated feeding station, fully automatic small bag feeding station, etc. | optional according to technical requirements |

| crusher | universal crusher, micro-crusher, air flow crusher, etc. | optional according to technical requirements | |

| screening, filtering | rotary vibrating screen, linear vibrating screen, air flow vibrating screen, etc. | optional according to technical requirements | |

| Batching system | feeding | powder part: spiral feeding, vibrating feeding, belt feeding, rotary valve feeding | screw variable frequency speed regulation, valve opening adjustable, feeding first fast and then slow, feeding speed adjustable Control |

| Weighing | Powder part: Weighing bucket, batching generally adopts weighing weight-increasing method, and can also adopt weighing weight-reducing method | Weighing module needs to select modules with different precision | |

| Conveying system | Conveying | Meet the requirements of internal conveying of production line equipment | Select according to capacity design, material characteristics, factory layout, etc. |

| Storage system | Storage | Suitable for intermediate storage of raw materials and finished products | Can shorten the time of mixing machine feeding and discharging, improve the utilization rate of mixer, and reduce production cost |

| Mixing system | Mixing | Horizontal ribbon mixer, horizontal plow mixer, horizontal zero-gravity mixer, vertical cone mixer | Select different mixers according to different material properties and mixing process requirements. |

| Packing system | Packing | Open bag packaging machine, valve bag packaging machine, ton bag packaging machine, etc. | Select the most suitable packaging machine according to packaging specifications, precision requirements, packaging efficiency, material properties, etc. |

In short, gypsum for powder sieve equipment plays an important role in the production, manufacturing and packaging process of gypsum powder. By using gypsum powder screening equipment, you can improve product quality, ensure the consistency of gypsum powder, improve production efficiency, reduce production costs, and meet the demand for high-quality gypsum powder in the building materials industry.