Application of Powder Sieving Machine in Metal Powder Processing

Tuesday March-11 2025 14:30:10

There are various types of metal powders, which generally refer to the group of metal particles with a size less than 1mm, and belong to loose powder substances.

What is the purpose of powder sieving machine in metal powder processing?

The impurities in the metal powder are removed and finely classified by the vibration of the sieve machine.

Processing materials: iron powder, alloy powder, zinc powder, metal powder, copper powder, tungsten powder, molybdenum powder, titanium powder, zirconia and other metal powder

Screening mesh: 2 mesh - 500 mesh

What is a powder sieving machine?

The Powder Sieving Machine performs separation and size determination of particles on the metal powder through the mutual cooperation of the vertical motor and the upper and lower eccentric weights. The amplitude of the sieve machine and the movement trajectory of the metal powder can be changed by adjusting the motor, and the discharge port can be set arbitrarily at 360°. With the arrangement of supporting equipment, it can be used in single or multiple layers according to actual production needs. Dust overflow, low noise (<75 decibels), low energy consumption.

Advantages of Powder Sieving Machine:

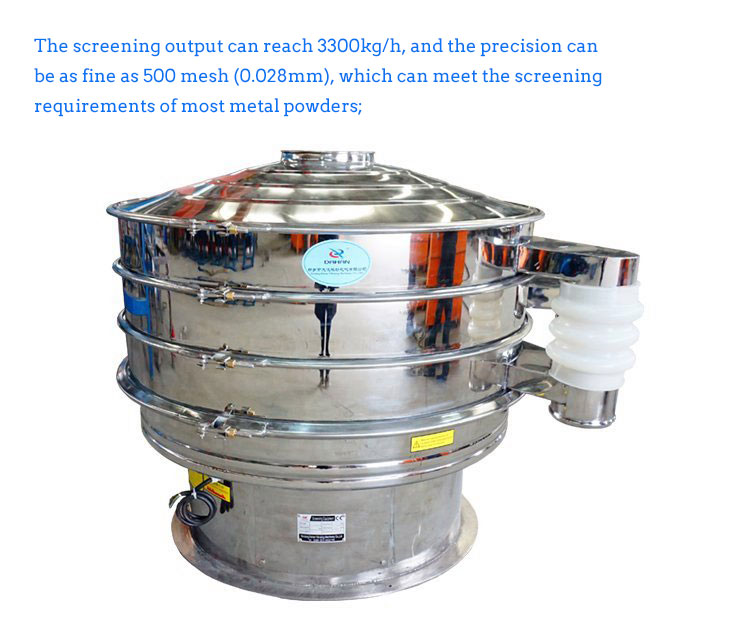

1. The screening output can reach 3300kg/h, and the precision can be as fine as 500 mesh (0.028mm), which can meet the screening requirements of most metal powders;

2. Each layer of sieve box is independent, easy to disassemble and assemble, and can clean up the hygienic corner where metal powder is easy to accumulate at any time;

3. Single-layer and multi-layer switching use, one machine meets the dual requirements of "separation and size determination of particles";

4. There are various cleaning devices to avoid metal powder blocking the screen and affecting the screening efficiency;

5. According to the characteristics of metal powder, edge design can be carried out to prevent powder from flying, or explosion-proof motor can be selected for safe production.

Applicable materials for powder sieving machine in metal powder processing

Aluminum powder: Commonly known as "silver powder", it has the characteristics of light powder, high buoyancy and strong hiding power. It is recommended to use airflow sieve or ultrasonic Powder Sieving Machine for sieving.

Magnetic material: It has the characteristics of high hardness, strong viscosity, easy clumping and easy flying, but the particle size of the product is relatively coarse (40-180 mesh), so it is difficult to use an ultrasonic rotary vibrating screen to achieve a good screening effect. It is recommended to use air flow Sieve for sieving.

If the metal powder to be sieved is prone to chemical reactions with various metal materials, there is also a Plastic Powder Sieving Machine that can be customized.

What is the use of powder sieving machine in metal powder processing ?

1. Particle size classification: The screening machine can classify the metal powder through screens with different apertures to ensure that the powder has a uniform particle size. It can also separate coarse particles from fine particles to ensure that the metal powder meets the requirements of use.

2. Remove impurities: There may be impure impurities in the metal powder, such as debris, contaminants, and oversized particles. The screening machine can effectively remove impurities and ensure the purity of the powder.

3. Improve powder fluidity: The metal powder particles after screening are more uniform, which helps to improve the fluidity of the powder. In some applications, such as powder metallurgy or 3D printing, good powder fluidity can improve the forming accuracy and product consistency.

4. Uniform distribution of metal powder particles: The screening machine can ensure that the metal powder has a uniform particle distribution during the processing process. This is particularly important for many applications such as powder metallurgy and 3D printing. Uniform particle distribution can improve the density and strength of the material.

5. Powder recovery and reuse: The screening machine can help recycle the wasted powder and reuse it. Through fine screening, metal powder that meets the particle size requirements can be effectively recovered, reducing resource waste and improving economic benefits.

6. Ensure product consistency: The precise screening of the sieving machine can ensure the quality stability of each batch of metal powder. For products that require high consistency (such as high-performance metal materials, precision parts, etc.), the sieving machine can effectively ensure the consistency of particle size, purity and distribution of each batch of powder to avoid batch differences.