What is Vibratory Sieve used for?

Saturday March-11 2023 14:51:48

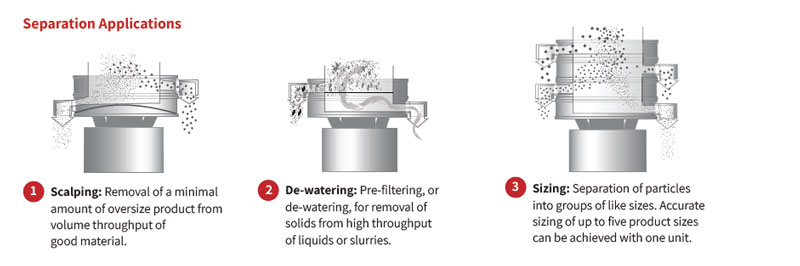

Vibratory Sieve is a widely used sieving machine, suitable for separation and size determination of particles in different forms such as granules, powders, liquids, etc. It can be designed in a variety of ways according to actual needs.

What is Vibratory Sieve used for?

1. Filter and remove impurities

The Vibratory Sieve adopts a detachable screen box design. The single-layer Vibratory Sieve can filter and remove impurities from materials with a lot of impurities. If you need to combine with the production line if you have high requirements for removal efficiency, you can choose to use a straight row sieve.

2. Uniform classification

By adding multiple screen boxes and multi-layer screens, the material can be screened layer by layer, up to 6 levels (5 layers). Vibratory Sieve can evenly sieve the materials in each sieve layer through three-dimensional motion. If you have higher requirements on the uniformity and fineness of material grading, you can choose the edged Vibratory Sieve.

Benefits of Vibratory Sieve

1. Screen 500 mesh fine materials

Vibratory Sieve's sieve can be as fine as 500 mesh (0.028mm), which can meet the screening requirements of powder and liquid materials. If the material is very fine and prone to static electricity and clumping, it is recommended to choose ultrasonic Vibratory Sieve and explosion-proof motor for safer production.

2. The screening output can reach 3t/h

The screening output of Vibratory Sieve is generally about 3-5 tons per hour for large models.

In addition, if you need to sieve corrosive and hygienic high-standard materials, you can use 304/316 stainless steel Vibratory Sieve, which can sieve those materials that are corrosive to acid and alkali and have high hygienic standards (lye coating, chlorine aluminum solution, flour, pharmaceutical preparations, food, etc.).