Introduction and demonstration of the working principle of Ultrasonic Vibrating Screen

Wednesday February-26 2025 10:31:35

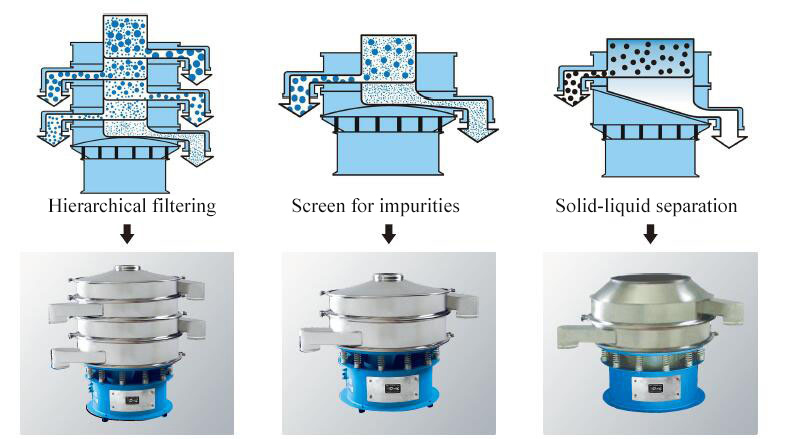

The Ultrasonic Vibrating Screen uses ultrasonic frequencies to vibrate the screen, making the mesh unclogged and making it easier to screen powders. The system increases screening capacity by a factor of 10, increasing productivity while allowing separations down to 20m (#635 mesh). This article will introduce the working principle of Ultrasonic Vibrating Screen in detail.

Ultrasonic vibrating screen is based on ordinary vibrating screen with ultrasonic screening system, which solves the screening problems of materials with strong adsorption, easy agglomeration, high static electricity, high precision, high density and light specific gravity, so as to improve the screening effect of ultrafine particles. The equipment increases the screening capacity by 10 times, improves productivity, and allows the separation of materials as low as 20m (#635 mesh).

What is the working principle of ultrasonic vibrating screen?

Ultrasonic Vibrating Screen is an ultrasonic screening system added on the basis of ordinary vibrating screens. It can input 220V, 50Hz or 110V, 60Hz electric energy into the ultrasonic transducer and convert it into 36KHz mechanical vibration. The generated ultrasonic waves make the screen mesh With high-frequency vibration, the vibration frequency can reach 36,000 times per second, which can make the fine powder material form a micro-suspension state on the screen, and can pass through the screen faster without generating static electricity and sticking to the screen, while achieving screening and cleaning. net effect.

The working principle of ultrasonic vibrating screen is the combination of ultrasonic technology and mechanical vibration.

1. The ultrasonic generator converts 220V 50Hz or 110V 60Hz electrical energy into high-frequency electrical energy of 36kHz to 40kHz.

2. These high-frequency electrical energies are input into the ultrasonic transducer and converted into mechanical vibration.

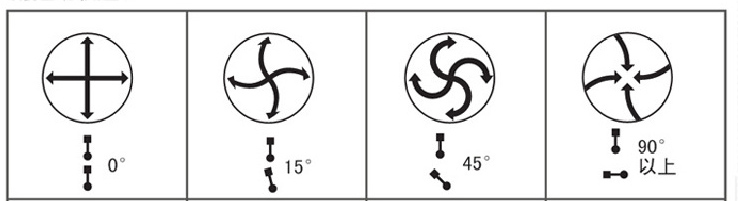

3. Mechanical vibration is used to generate high-frequency vibration on the screen, so that the material on the screen performs low-frequency oscillation while being excited by ultrasonic waves.

4. Due to the high-frequency vibration and compression of ultrasonic waves, it is easier for the material to pass through the sieve holes. At the same time, the vibration force causes the material to vibrate and impact on the screen surface, achieving an efficient screening process.

5. Ultrasonic vibrating screen can also effectively remove blockage problems such as adhesion, agglomeration, and static electricity on the screen, thereby maintaining the continuity and efficiency of screening.

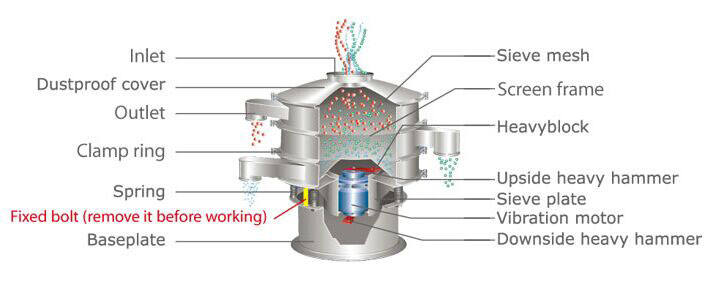

What are the parts of ultrasonic vibrating screen?

1. Ultrasonic resonance power supply: 38KHz high-frequency and high-power ultrasonic resonance power supply, with built-in microcomputer chip, which can automatically track all-digital frequencies according to different states of ultrasonic waves, without manual adjustment, and is simple and convenient to operate. The oscillator generates less heat when working for a long time and the working condition is stable.

2. High-frequency connecting line: The ultrasonic oscillator and the ultrasonic resonant power supply are connected through cables.

3. Connector: aviation connection plug-in.

4. Oscillator: high-performance ultrasonic conversion device.

5. Ultrasonic grid: composed of outer grid and resonance ring.

6. Ultrasonic vibrating screen: suitable for 10 mesh to 635 mesh.

Due to the unique sieving principle of Ultrasonic Vibrating Screen, it is easy to sieve fine powder materials under low-amplitude and high-frequency vibration conditions. Throughput, it can effectively screen 600 mesh ultrafine powder.

Ultrasonic Vibrating Screen manufacturers

| Model | Test Material | Mesh Size | Test Results | |

| Vibrating Screen | Ultrasonic Vibrating Screen | |||

| φ1000 | Silicon carbide | 500 mesh | Cannot be sieved | 1500kg/h |

| φ1000 | Tungsten powder | 600 mesh | 15 minutes without sifting out fine powder | 30kg/h |

| φ1000 | Cobalt powder | 400 mesh | 10kg/h | 300kg/h |

| φ1000 | NdFeB powder | 300 mesh | 32.2% sieve residue in 30 minutes | 6.9% sieve residue in 30 minutes |

| φ1000 | Gold steel sand powder | 300 mesh | Cannot be sieved | 1300kg/h |

| φ1200 | Antimony trioxide | 80 mesh | 700kg/h | 2000kg/h |