Application of test sieve for wet screening of materials

Monday May-12 2025 16:02:11

Test sieve wet for screening is a method commonly used for particle size analysis, especially for feed that is easy to absorb moisture, easy to agglomerate, fine in particle size, or easy to clog the screen in dry screening. It assists screening by adding a diluent liquid (usually water) to improve screening efficiency and accuracy.

Applicable materials for test sieve wet for screening

Viscous materials: such as kaolin, bentonite, talcum powder, etc. These materials are easy to agglomerate and clog on the surface of the sieve, and wet screening can effectively disperse the particles.

Fine powder materials: such as quartz powder, calcium carbonate, wollastonite powder, spodumene powder and other ultra-fine particles, can be flushed with water to prevent the agglomeration of particles caused by static electricity or adsorption.

Samples with solutions: such as some chemicals, slurry samples, and mud materials are already in a wet state, so it is more reasonable to directly perform wet screening.

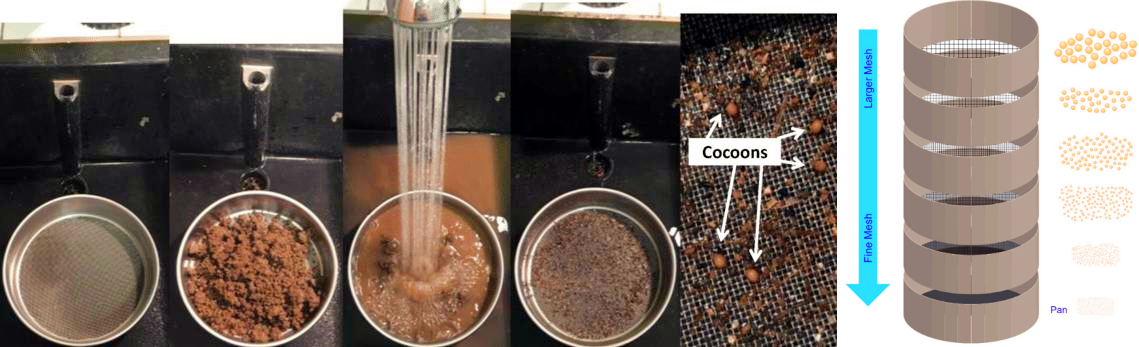

Principle of test sieve wet for screening

Test sieve wet for screening is to put the material into water or liquid, use test sieve wet for screening (such as vibrating screener) to make the material pass through screens of different apertures, and separate materials of different particles according to the dispersion and sedimentation characteristics of wet screening in water. Compared with dry screening, wet screening can better handle sticky materials, fine particles or materials that are easy to agglomerate, and can evaluate the water stability of materials.

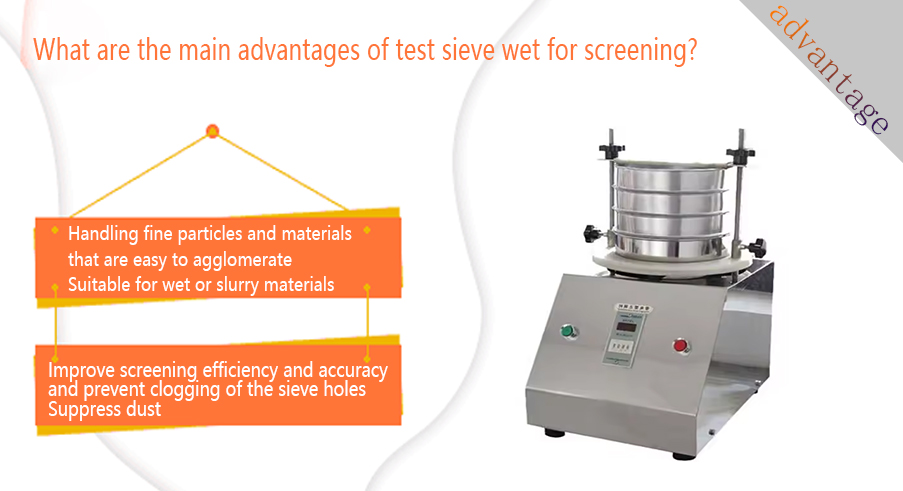

What are the main advantages of test sieve wet for screening?

Handling fine particles and materials that are easy to agglomerate: Many very fine powders tend to agglomerate in the dry state due to static electricity, surface forces or van der Waals forces, forming larger particle agglomerates, which make it impossible to pass through the sieve holes that they should have passed through. During dry screening, these agglomerates will remain on the sieve, making the measurement of fine particle content inaccurate. Test sieve wet for screening can disperse these agglomerates and suspend independent fine particles in the liquid. Through flushing or vibration, fine particles are more likely to pass through the sieve holes with the liquid, thereby achieving effective separation.

Suitable for wet or slurry materials: Some materials are inherently wet, damp, or in the form of slurry/suspension. Direct dry screening is very difficult or impossible. Test sieve wet for screening is the only or more convenient way to handle such materials. The slurry can be poured directly into the sieve and the liquid flow can be used to assist in screening.

Improve screening efficiency and accuracy and prevent clogging of the sieve holes: For some materials containing a large amount of fine powder, the fine powder is easy to embed or adhere to the sieve holes during dry screening, causing clogging and affecting accuracy. Liquid can wash away the fine particles adhering to the sieve, keep the sieve holes unobstructed, and improve the screening speed and thoroughness.

Suppress dust: Many fine dry powders will generate a lot of dust during the screening process, which not only causes material loss, but also has an adverse effect on the health of operators and the environment. Test sieve wet for screening is carried out in a liquid environment, which can effectively suppress the generation of dust, improve the operating environment, and reduce safety risks.

Application of test sieve wet for screening

1. Soil science

Determination of water stability of soil aggregates: Test sieve wet for screening is used to analyze the water stability of large soil aggregates (particle size > 0.25mm). For example, the degree of soil disintegration in water is determined by wet screening, and the water stability of the screened aggregates is calculated to calculate their proportion of soil mass. This is essential for evaluating soil structure, antimicrobial capacity and fertility.

Soil particle size analysis: Wet screening can be used to determine the distribution of fine particles in soil, especially in soils with high mud or silt content.

2. Building materials

Screening of coarse aggregates and mixtures: Test sieve wet for screening is used to analyze the particle size composition of coarse aggregates such as crushed stone, slurry stone, and slag, and evaluate their applicability in cement concrete.

Fine aggregate test: Test sieve wet for screening is used to determine the particle size distribution of sand to ensure the rationality of concrete mix ratio.

3. Pharmaceutical Industry

Pharmaceutical Analysis: Wet sieving is used to determine the particle size distribution of drugs or pharmaceutical excipients to ensure that the quality of the preparation meets the pharmacopoeia standards (such as the Chinese Pharmacopoeia and the European Pharmacopoeia). Sieve meshes of different standards are used to meet specific specifications.

4. Chemical and Powder Materials

Powder Particle Size Detection: Test sieve wet for screening sieving is suitable for particle size analysis in the fields of chemical raw materials, powder metallurgy, etc., and is particularly suitable for processing fine or easily agglomerated output materials. The test sieve equipment achieves efficient screening through high-frequency vibration, with low phase and good repeatability.

The test sieves wet sieving materials are widely used and play an important role in various fields. It can improve product quality, optimize production processes, reduce costs, and provide a good raw material basis for subsequent processing and application.