To judge whether the sample needs dry sieving method or wet sieving method, there are three judgment criteria as follows:

1. The dry sieving method cannot meet the requirements of sample separation

2. There is a small amount of granular agglomeration in the sample

3. It is necessary to remove the silt or clay attached to the sample

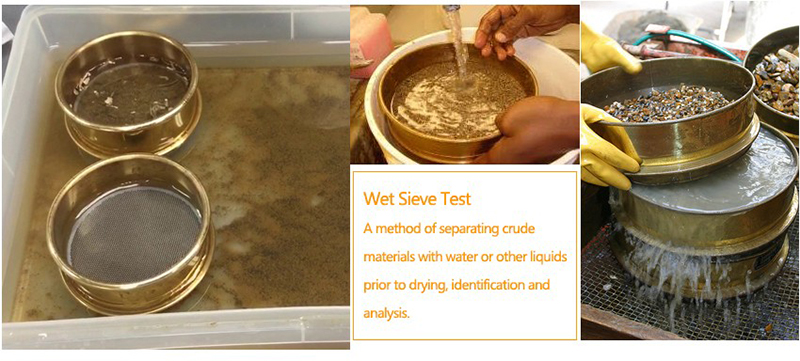

Wet Test Sieve is used in the wet sieving procedure for sample analysis. It can be used to remove fine materials that are difficult to sieve before sample drying and testing. The processed materials need to have the following characteristics:

1. Insoluble in water

2. Does not expand and deform when exposed to water or humidity

3. The material is not sensitive to temperature changes and can maintain its shape at 110°C without changing

| Material type | Example | Characteristics | Mesh number recommendation | Application scenario |

| Soil/geological samples | wet soil, mud | high water content, viscosity | 10-200 mesh | soil particle size analysis |

| Mineral/ore slurry | coal slime, iron ore powder | wet, fine | 50-200 mesh | mineral fineness detection |

| Organic fertilizer/compost | wet compost, manure | high humidity, viscosity | 20-80 mesh | fertilizer particle screening |

| Chemical powder | wet rubber powder, pigment slurry | wet sticky, fine | 80-200 mesh | powder particle size analysis |

| Food/agricultural products | fruit residue, wet flour | wet soft, sticky | 30-120 mesh | food residue screening |

| Environmental samples | sludge, sediment | high water content, complex | 50-150 mesh | environmental monitoring |

| Other wet and sticky materials | wet cement slurry, fly ash | viscous, low fluidity | 40-120 mesh | industrial material classification |

The wet sieve test is also a method for analyzing the particle size distribution of samples, and it is used to remove small sample materials that may be difficult to sieve. The wet sieve test can be performed according to the following tips:

A. Before starting the analysis, weigh the total sample. The sample should be dry at this time.

B. If time permits, soak the sample to make the test analysis easier.

C. Add deflocculants such as sodium hexametaphosphate or Calgon to the soaking solution to decompose the clumped samples and disperse the sample particles.

D. Use a nozzle or sprayer to evenly wet the sample during sieving or stirring.

E. Use gentle, controlled water pressure to prevent accidental sample loss and damage to the screen.

1. Made of non-rusting material, it will not rust or corrode due to long-term use in a humid environment;

2. Meet the ISO6106 standard, and can promise to design the sieve according to the laboratory analysis standard;

3. The Wet Test Sieve of the same model is guaranteed to have consistent nesting;

4. The opening of the mesh surface is uniform and the opening rate is high;

5. The mesh hole is consistent, the mesh surface is smooth, the sample is not damaged and the sample can flow freely;

6. The edge of the screen frame is curled for safe operation.

Wet Test Sieve is applied in wet sieving, and it is an ideal treatment method for fine powder samples that are easy to agglomerate and cause their own particle false changes to affect the accuracy of sieving. include:

Soil and mineral aggregates with high fines content

Fragile but insoluble materials such as coal or other minerals

light powder

Sludges and Glazes

Kaolin and fillers

Abrasives

microparticles

| NO. | Name | Unit | Parameter |

| 1 | frame diameter | mm | φ200 |

| 2 | the number of layer | s | 1~8 |

| 3 | sieve size | mm | 0.025-3 |

| 4 | vibrating amplitube | mm | 1~4 |

| 5 | vibration frequency | n/min | 1440 |

| 6 | power supply | V;HZ;KW | 220;50;0.12 |

| 7 | outside dimension | LWH | 350*350*(300+n*56) |

| 8 | machine weight | kg | 36 |

| 9 | time alarm | s | 999 |

| 10 | noise | db | Less than 50 |

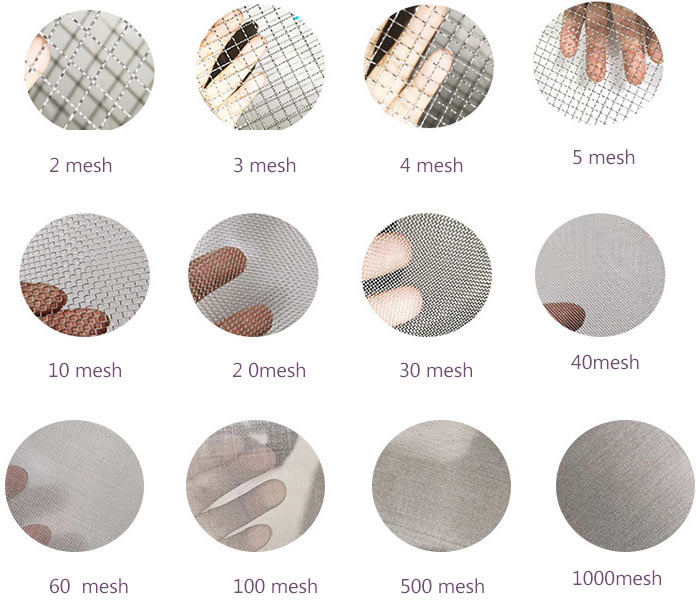

Wet Test Sieve screens are available in three forms: metal perforated plate screens, wire woven screens, and electroformed screens.

The punching plate screen has the largest opening, and the punching machine punches uniform and standard screen holes on the stainless steel metal plate. It is the most solid screen form and is suitable for the analysis of large particles, blocks, and abrasive samples, such as Rocks, abrasives, etc.

The wire woven screen has small openings and is suitable for the analysis of particles and powder samples. The pressure bearing capacity is weak, and strong impact screening should be avoided.

The electroforming screen is suitable for the precise sample analysis of the machine. The mesh is the most dense, but the screen is also the most fragile. It is only suitable for a small amount of sample analysis and is easy to break. Generally, the screen surface is supported by a grid.

The screen mesh sizes shown here are for wire woven screens and electroformed screens only.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

| Features | Wet screening | Dry screening |

| picture |  |

|

| Applicable materials | Materials with high moisture content, high viscosity or easy to agglomerate | Dry materials with good fluidity |

| Screening method | Screening in water or liquid medium | Screening directly in the air |

| Applicable particle size | 5μm ~ 2mm (applicable to ultrafine powder) | 40μm ~ 100mm (applicable to larger particles) |

| Whether to dry | Generally, the sample needs to be dried before weighing | No additional drying treatment is required |

| Screening accuracy | Higher, can prevent fine powder from agglomerating and improve classification accuracy | Low accuracy, prone to blockage and misscreening |

| Applicable industries | Chemical, pharmaceutical, food, ceramics, metallurgy, mineral processing | Construction, ore, sand and gravel, grain, plastic particles |

1. Solve the limitations of dry screening and improve the screening efficiency and accuracy of fine particle materials.

2. Liquid media can disperse particles, reduce interactions between particles, and improve screening accuracy

3. Screen suspensions to determine the particle size distribution of solid particles and expand the scope of application

4. Reduce particle aggregation and static electricity, provide accurate particle size distribution results, andaccuracy

bismuth tungstate--500 mesh

sieve shaker for testing soil

how to use sieve shaker