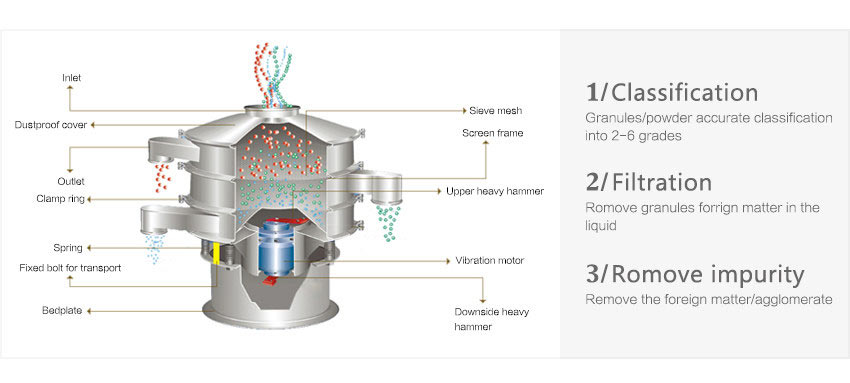

1. 1-5 layers of detachable screens can realize multiple functions such as impurity removal, separation, and filtration, and can be adjusted in time according to the processing requirements of different materials;

2. The 2-500 mesh screen can handle materials in various states from particles to liquids, and has a wide range of applications;

3. The screen is flat and smooth, with a variety of options to ensure that the materials to be separated can be evenly dispersed on the screen and selected according to requirements;

4. It can be connected to the feeding and discharging device, which can realize assembly line production and automatic feeding and discharging.

Vibratory Separator usually has 3 types of wire mesh, perforated plate mesh and nylon mesh.

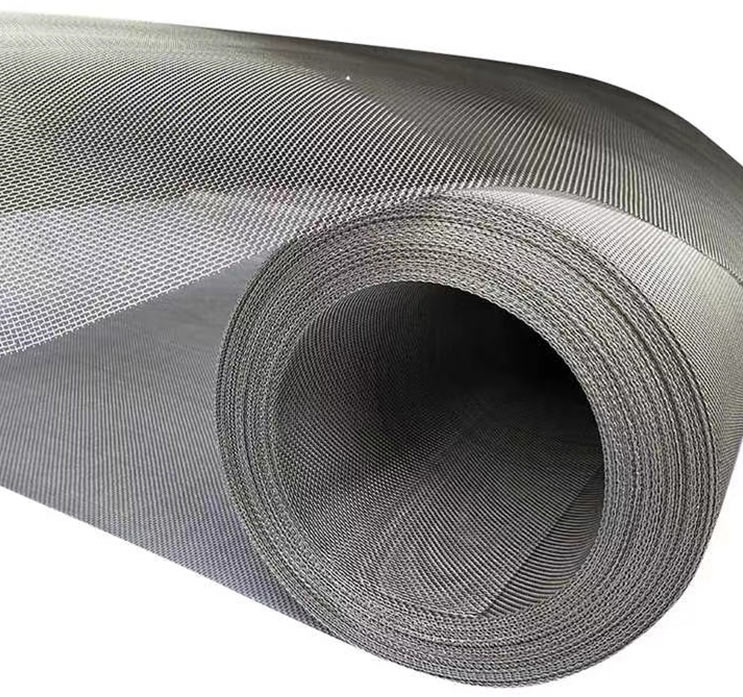

1. Metal wire woven screen

The common Vibratory Separator screen type is used in the screening of light and fine particles, powder or liquid, and is usually supported by a grid to ensure the smoothness and service life of the screen.

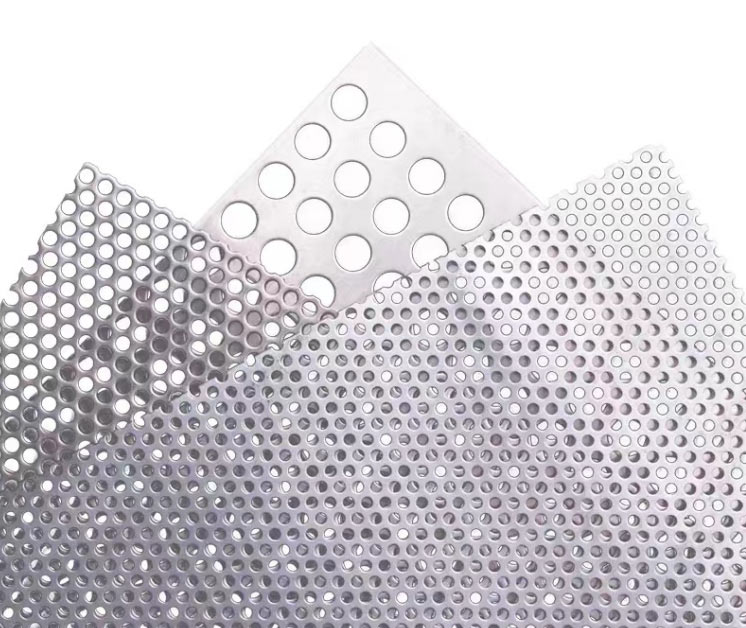

2. Perforated plate screen

Mechanical punching is used for the removal and classification of particles or small pieces of materials with strong abrasiveness. The edge of the mesh is smooth, the opening is uniform and the opening rate is high, and the screening efficiency is high.

3. Nylon mesh

The special screen material is generally used for the screening of chemical additives that cannot be in contact with metals, and is usually used together with a nylon vibrating screen.

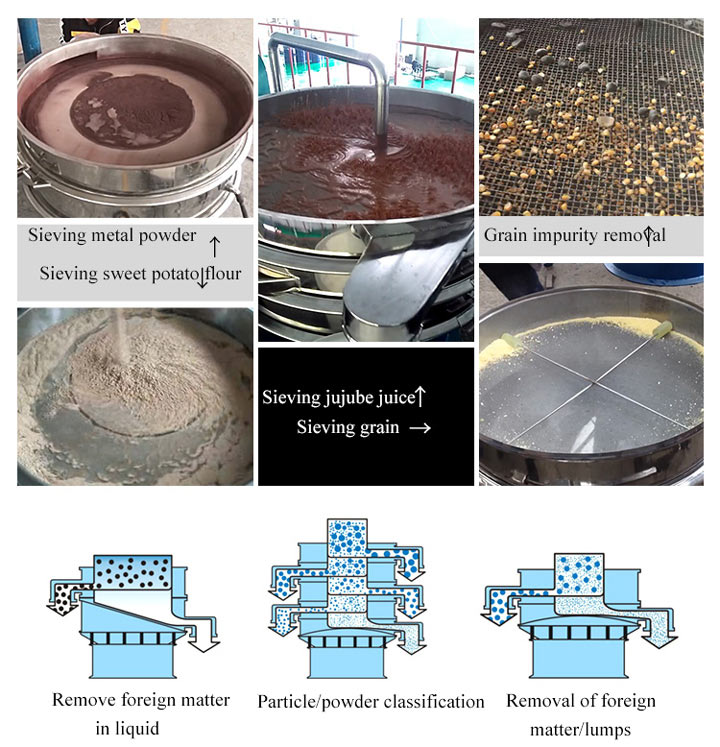

Vibratory Separator can be used for solid-liquid separation, particle size classification, and particle homogenization.

Impurity removal: It can remove large particles and foreign matter in powder or granular products, as a guarantee for fine processing of products or final quality inspection before packaging.

Grading: 1-5 layers of sieves can obtain 2-6 kinds of products with different particle sizes.

Filtration: Quickly remove insoluble solid particles or suspended matter in the slurry.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

The key structure of the Vibratory Separator is that different mesh screens separate materials with different specifications.

The number of screen layers required for installation, through the exciting force generated by the motor, the materials are evenly dispersed on the screen surface and the materials that meet the specifications fall into the lower screen for further separation, completely eliminating the steps of manual processing.

| Special design | Feature | Effect | Picture |

| edge type | Feed inlet heightened | Reduce powder and liquid splashing |  |

| observation window | Sealed sieve cover with observation window | Keep abreast of material screening |  |

| gate type | Add a movable gate to the discharge port | Extend the screening time for difficult screening materials |  |

| Anti-corrosion plastic | Polypropylene material | Screens corrosive and metal-reactive materials |  |

| Explosion-proof | Enhanced sealing, BZDL explosion-proof vertical vibration motor | Special industries, explosive materials screening use |  |

| feed bin | Add material storage bin with valve | No manual feeding is required, and the material flow is controllable |  |

| special coating | Teflon coating is sprayed inside the screen frame | More wear-resistant, special materials are used for screening |  |

| Ultrasonic system | Add ultrasonic device | Light and fine, electrostatic powder screening |  |

Vibratory Separator is an automatic material separation machine. Its function is to perform screening, impurity removal and filtration with high efficiency and large output. It is used in conjunction with the factory's production line to save time and a lot of labor costs.

1. Food separation

It is an extremely wise choice to use Vibratory Separator for food separation. In fact, many factories have done this. The Vibratory Separator made of 304 or 316L stainless steel can provide you with the screening and removal of food raw materials, such as soybeans, corn, nuts, etc., under the premise of ensuring food safety; or for powdered foods, such as coffee, cocoa powder, spices, Flour, etc. for impurity removal or packaging grading; it is also a good choice for processing a small amount of fruit juice.

2. Industrial screening<

In the industrial field, the Vibratory Separator still has a broad market, such as the initial treatment of plastic granules, feed, sand and gravel, and even industrial wastewater in environmental protection. It can separate industrial granular solids according to the specifications of the application requirements, and further flocculants are required. The added industrial wastewater is treated with impurity removal and filtration, which can be perfectly integrated into the production line. The sealed design does not need to worry about dust pollution or liquid leakage.