1. The circular sieve box, the discharge port can be freely rotated 360°, which can flexibly adapt to the layout of production equipment;

2. Compact structure, occupy less factory area, and achieve greater production efficiency;

3. The sealing ring made of rubber or silicone material ensures good sealing performance, without material loss or production environment pollution;

4. The circular design can make the entry and exit of materials more smooth, and avoid the situation of material accumulation caused by the existence of angles.

The Circular Sieve is available in different models, suitable for the home, small workshop or large processing plant. It can be used for solid-liquid separation, particle size classification, and particle homogenization, etc.

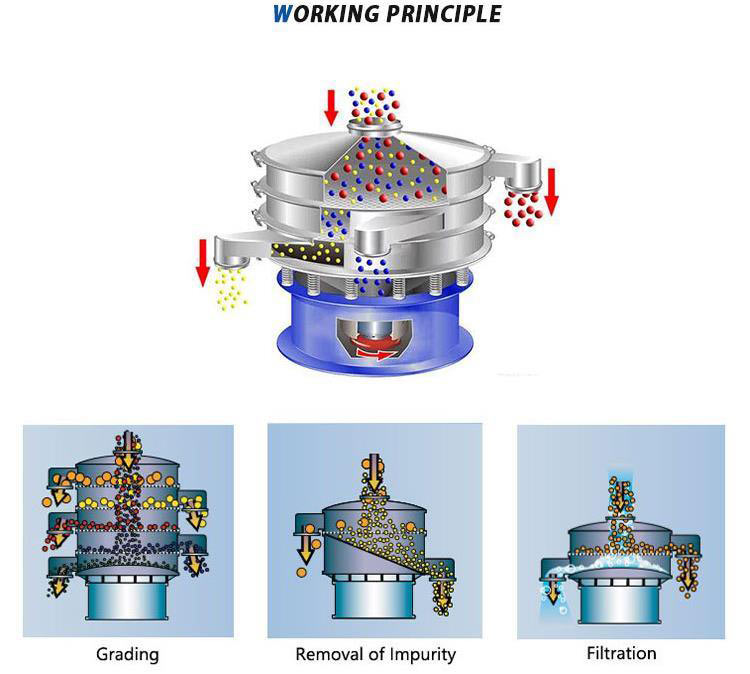

Impurity removal: It can remove large particles and foreign matter in powder or granular products, such as flour, medicinal powder, condiments, etc., which is the guarantee for the final quality inspection of products before fine processing or packaging.

Grading: 1-5 layers of sieves can obtain 2-6 kinds of products with different particle sizes.

Filtration: Quickly remove insoluble solid particles or suspended matter in the slurry.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

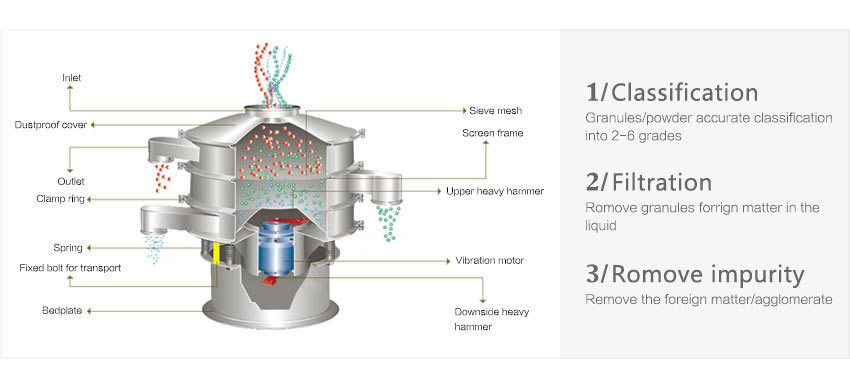

Dust cover: It is composed of a feed inlet and an inclined cone, and the lower end is connected with the screen frame to prevent the dust in the workshop from falling into the material when the vibrating screen is working. Commonly used materials are stainless steel, carbon steel and plastic. And so on 3 kinds of materials.

Screen frame: It is rolled and welded by steel plate, with load-bearing rings at the upper and lower ends, and flange rings at the lower part, which are used to fix the structure of the screen components.

Vibration motor: vertical vibration motor, divided into four specifications: 2, 4, 6, 8, and grades, the vibration times are 2870, 1460, 980, 740RPM respectively, and can be designed as explosion-proof type (inflammable and explosive occasions)

Screen mesh: models include φ600, 800, 1000, 1200, 1500, 1800, etc., and materials include stainless steel, carbon steel, and plastic.

Screen cleaning device: clean up the clogged materials in the screen holes to increase the output. It is made of silicone and rubber. An ultrasonic cleaning device (635 mesh) can also be selected.

Damping springs: There are 12-20 vibration isolation springs along the vibration transmission body. The base is welded from steel coils. There are inspection doors and electrical switch holders on the bottom wall. An annular flange is welded on the upper part of the base wall, and the flange is connected with the vibration transmitting body through a vibration isolation spring.

| Special design | Feature | Effect | Picture |

| edge type | Feed inlet heightened | Reduce powder and liquid splashing |  |

| observation window | Sealed sieve cover with observation window | Keep abreast of material screening |  |

| gate type | Add a movable gate to the discharge port | Extend the screening time for difficult screening materials |  |

| Anti-corrosion plastic | Polypropylene material | Screens corrosive and metal-reactive materials |  |

| Explosion-proof | Enhanced sealing, BZDL explosion-proof vertical vibration motor | Special industries, explosive materials screening use |  |

| feed bin | Add material storage bin with valve | No manual feeding is required, and the material flow is controllable |  |

| special coating | Teflon coating is sprayed inside the screen frame | More wear-resistant, special materials are used for screening |  |

| Ultrasonic system | Add ultrasonic device | Light and fine, electrostatic powder screening |  |

Circular Sieve is widely used in mining, building materials, metallurgy, casting, abrasives, cement, chemical industry, medicine, light industry, glass and coating industries for dry and wet screening of materials and separation and recovery of solids in liquids. It can also be used for waste water screening Filtration recovery and other operations.

Chemical industry: resin, paint, pigment, medicine, cosmetics, fire extinguishing agent, plastic powder, etc.

Abrasives: glass, ceramic industry abrasives, alumina, porcelain slurry, clay slurry, glass powder, refractory materials, quartz sand, etc.

Food industry: sugar, monosodium glutamate powder, salt, fruit juice, starch, milk powder, grain, soybean milk, egg powder, etc.

Metallurgical industry: ore, zinc oxide, zinc oxide, foundry sand, metallurgical powder, superhard alloy, aluminum powder, various metal powders, etc.

Others: carbon black powder, co-solvent, activated carbon, electromagnetic materials, pearls, etc.