Centrifugal Sifter, also known as rotary sieving machine, is an industrial powder sieving machine, which is used to process powder materials with less impurity content. The ability to attach loosely agglomerated powders together.

Centrifugal Sifter utilizes the characteristics of light weight, fine powder and easy floating of powder to diffuse the powder into the air through wind force, and the powder meeting the fineness requirements is ejected through the screen to achieve the purpose of screening. It has the advantages of high efficiency, large output, non-stick screen, non-blocking screen, and accurate fineness.

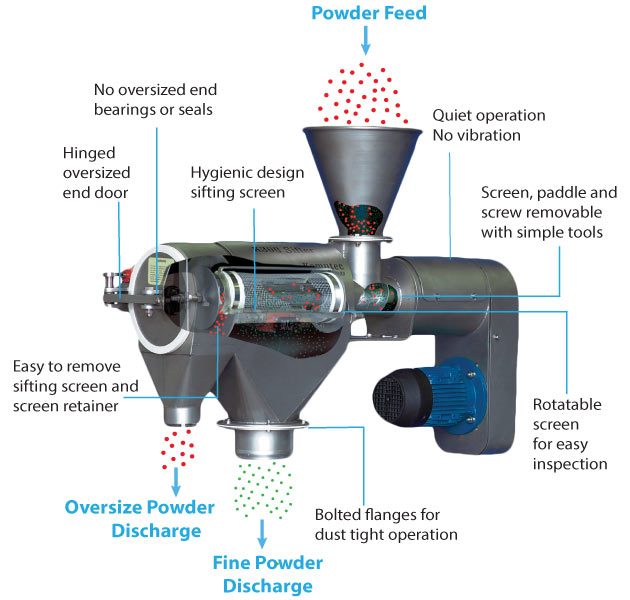

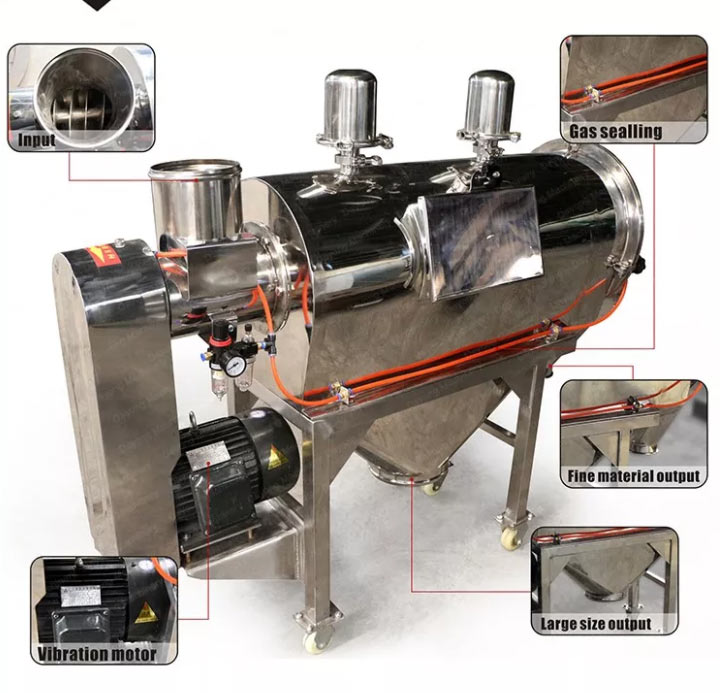

The screen of Centrifugal Sifter is installed in the screen box in a cylindrical shape. The material enters the chamber formed by the screen box and the screen. The central rotor and fan blades are driven by the motor to generate airflow to form wind force. The material is driven by the wind force. hit the screen. The material with large particles is intercepted in the chamber formed by the screen, and the material that meets the specifications passes through the screen to complete the separation of the material

Centrifugal Sifter can use wind power to process small and light powder materials of 80-600 mesh. It has two main functions:

1. Screening function

A layer of sieve is placed in the horizontal sieve box of Centrifugal Sifter, and the wind force generated by the wind wheel blades in the sieve box blows away the powder material entering it, causing it to hit the sieve and be sieved. Because only one layer of screen can be installed, only simple screening or impurity removal can be performed. However, any screen mesh within the mesh size can be replaced as required.

2. Crushing function

The Centrifugal Sifter has a simple screw conveying system structure, and the blades of the wind wheel with strong wind in the screen box are constantly rotating, which can crush the falsely agglomerated materials.

1. High-precision screening: the screening is as fine as 80-600 mesh, and the screening efficiency is above 95%;

2. Boring is not easy to block: the screen can be cleaned by itself under the impact of the cyclone, and at the same time it has the function of re-breaking the agglomerated materials, reducing the possibility of blockage;

3. Large output and labor saving: it can be used together with various mills and air ducts. After screening and using materials such as rubber additives and light calcium, the measured output is 1 ton/m2/h, which is 5-10 times or higher than ordinary vibrating screen;

4. Closed and dust-free: With closed design, the entire screening environment is free of dust, avoiding cross-contamination of materials caused by mixing materials.

| Model | A | B | C | D | E | F | G | H | I | J |

| WQS18-65 | 1430 | 460 | 420 | 1005 | 135 | 230 | 250 | 330 | 340 | 210 |

| WQS30-100 | 1845 | 655 | 766 | 1240 | 320 | 285 | 300 | 350 | 380 | 290 |

| WQS50-130 | 2230 | 870 | 790 | 1775 | 280 | 515 | 150 | 660 | 400 | 485 |

| Model | Material | Power | Application |

| WQS18-65 | Q235A | 2.2KW | Screening below 500 mesh |

| SUW304 | |||

| WQS30-100 | Q235A | 4KW | |

| SUW304 | |||

| WQS50-130 | Q235A | 5.5KW | |

| SUW304 |

The main part of Centrifugal Sifter is composed of "drive motor, screw conveying system, wind rotor blades, grid frame".

The driving motor is used as the power source to drive the blades of the wind turbine to generate wind energy, which will be sent into the screen box by the screw conveying system. The wind energy generated by the blades makes the light and fine powder materials in a state of flying and impacts through the net to complete the screening of materials.

Centrifugal Sifter has been successfully applied to 120-180 mesh light calcium, 300 mesh heavy calcium, 400 mesh active calcium, 300 mesh hawthorn powder, 320-500 mesh zinc powder, 500 mesh iron oxide black and other materials, and good screening results have been achieved. The measured screen area is about 1 ton per square meter per hour, the screening accuracy is above 95%, and the air dust content is less than 10mg/m3.

Can be used in:

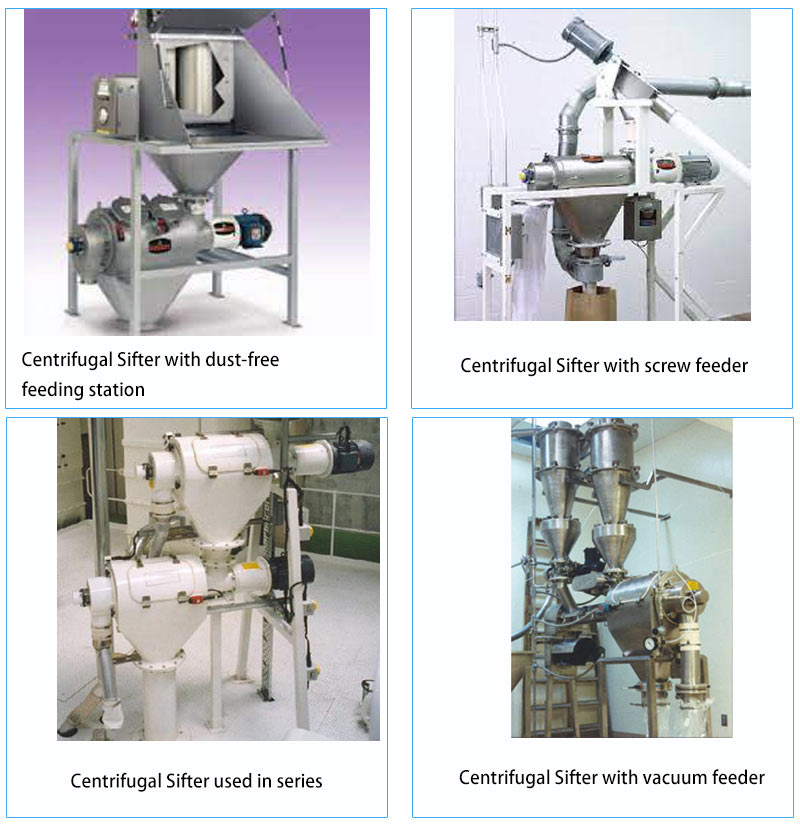

1. Food industry: flour sieving, ingredient inspection and screening, milk powder screening, baking mix de-agglomeration and final dressing

2. Chemical industry: general fine powder classification, nylon fleece depolymerization, powder depolymerization, powder coating inspection and screening

3. Pharmaceutical industry: check the screening of raw materials and the classification of active ingredients of drugs